MODEL: UFGG – UNIVERSAL FLUTE AND GUNNOSE GRINDER

FLUTE SERIES

ITM holds over 30 patented machine designs

ECONOMICAL SOLUTION FOR HIGH PRODUCTIVITY FLUTE GRINDING

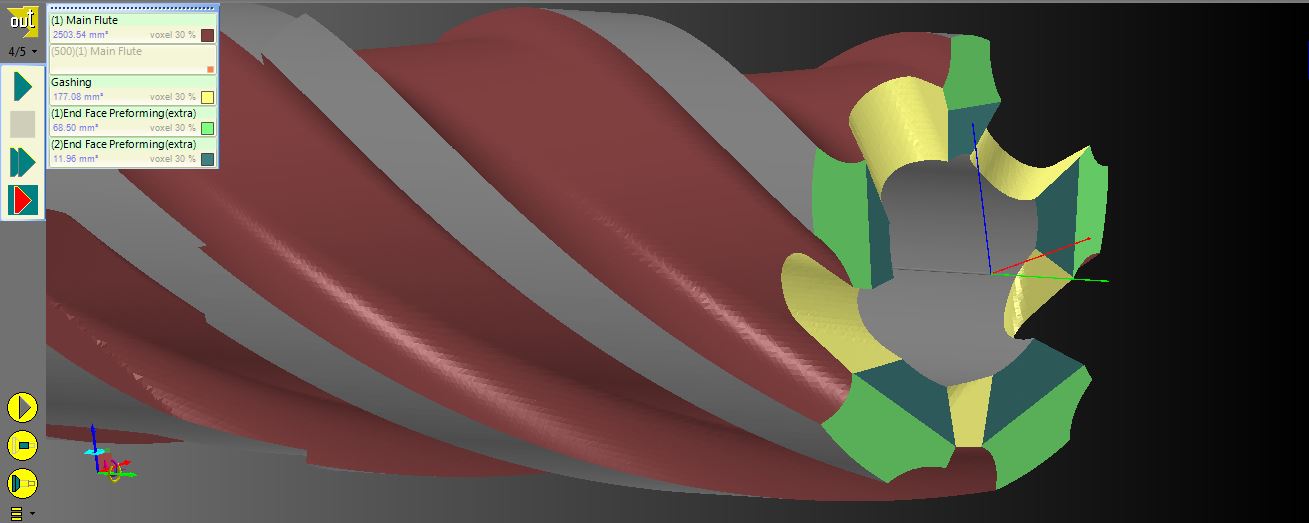

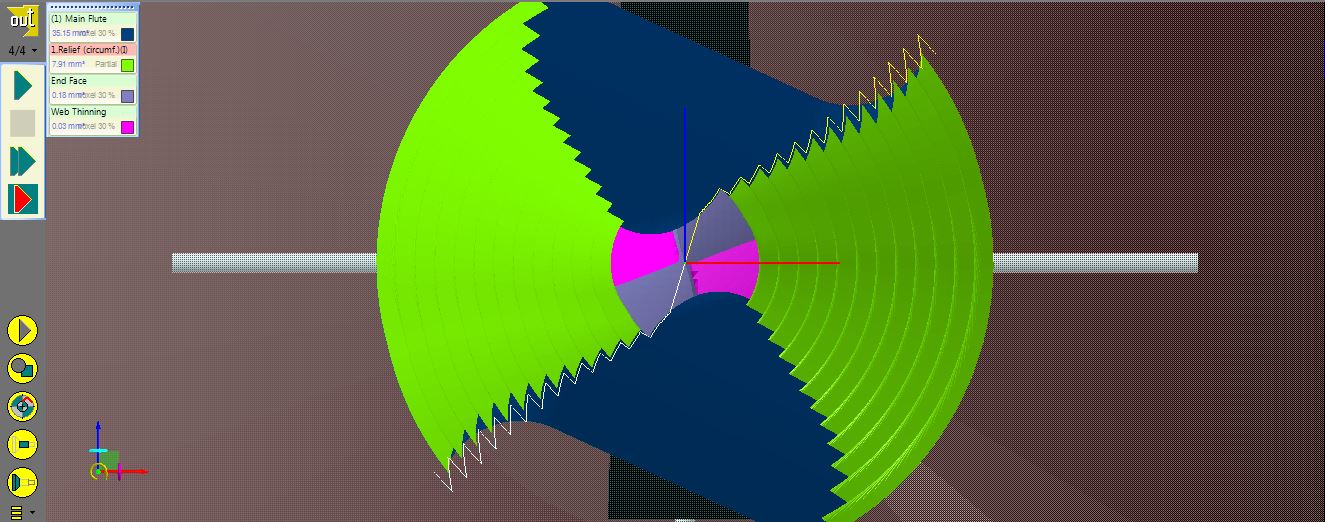

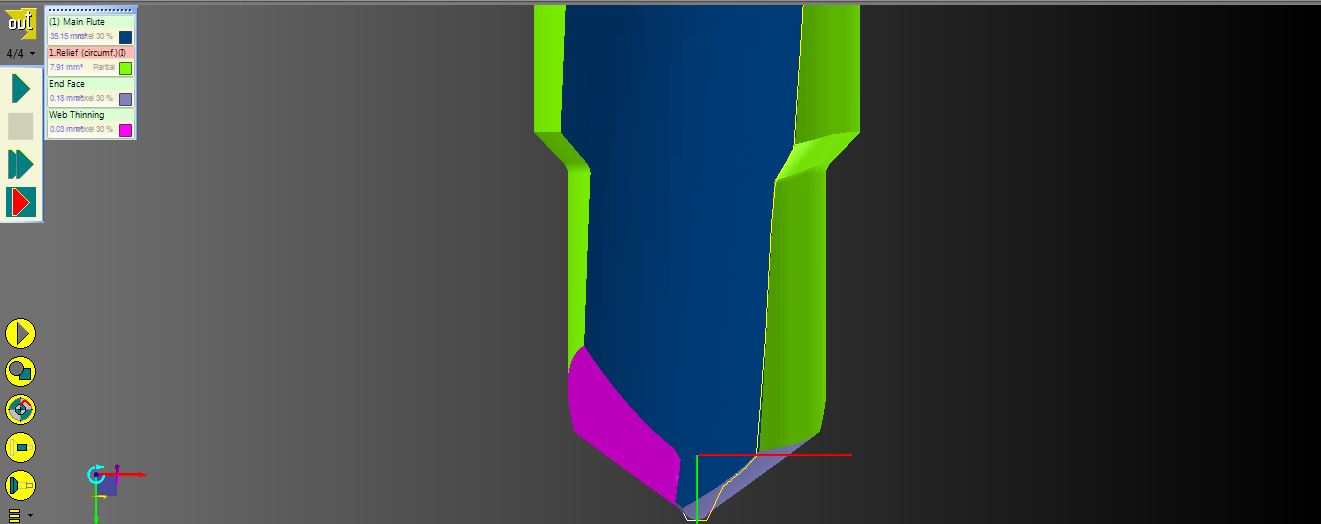

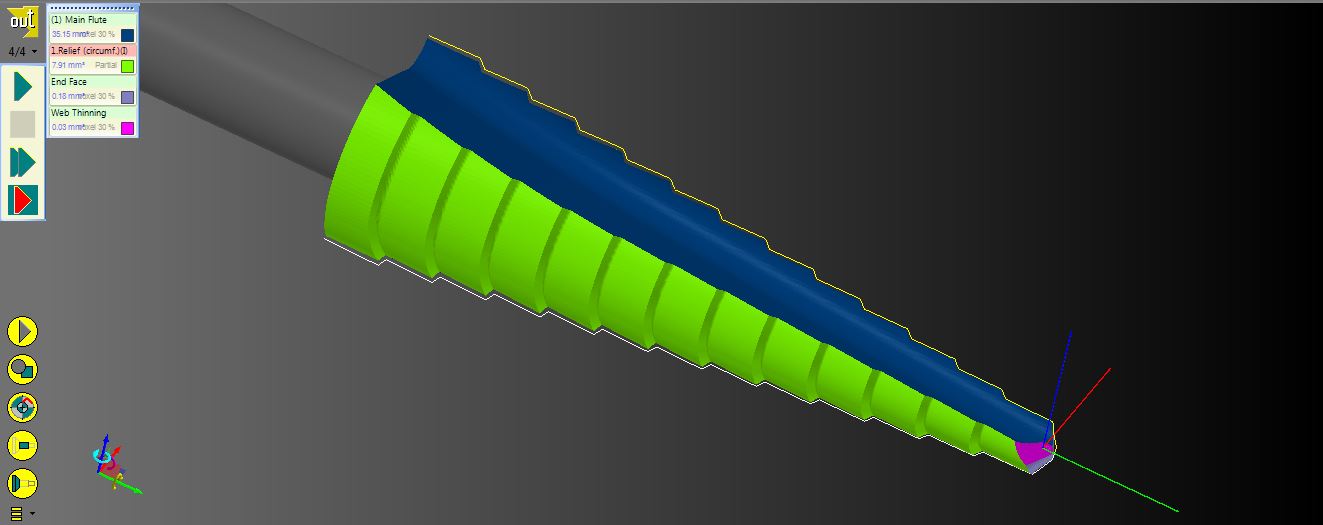

Precision Flute Grinding

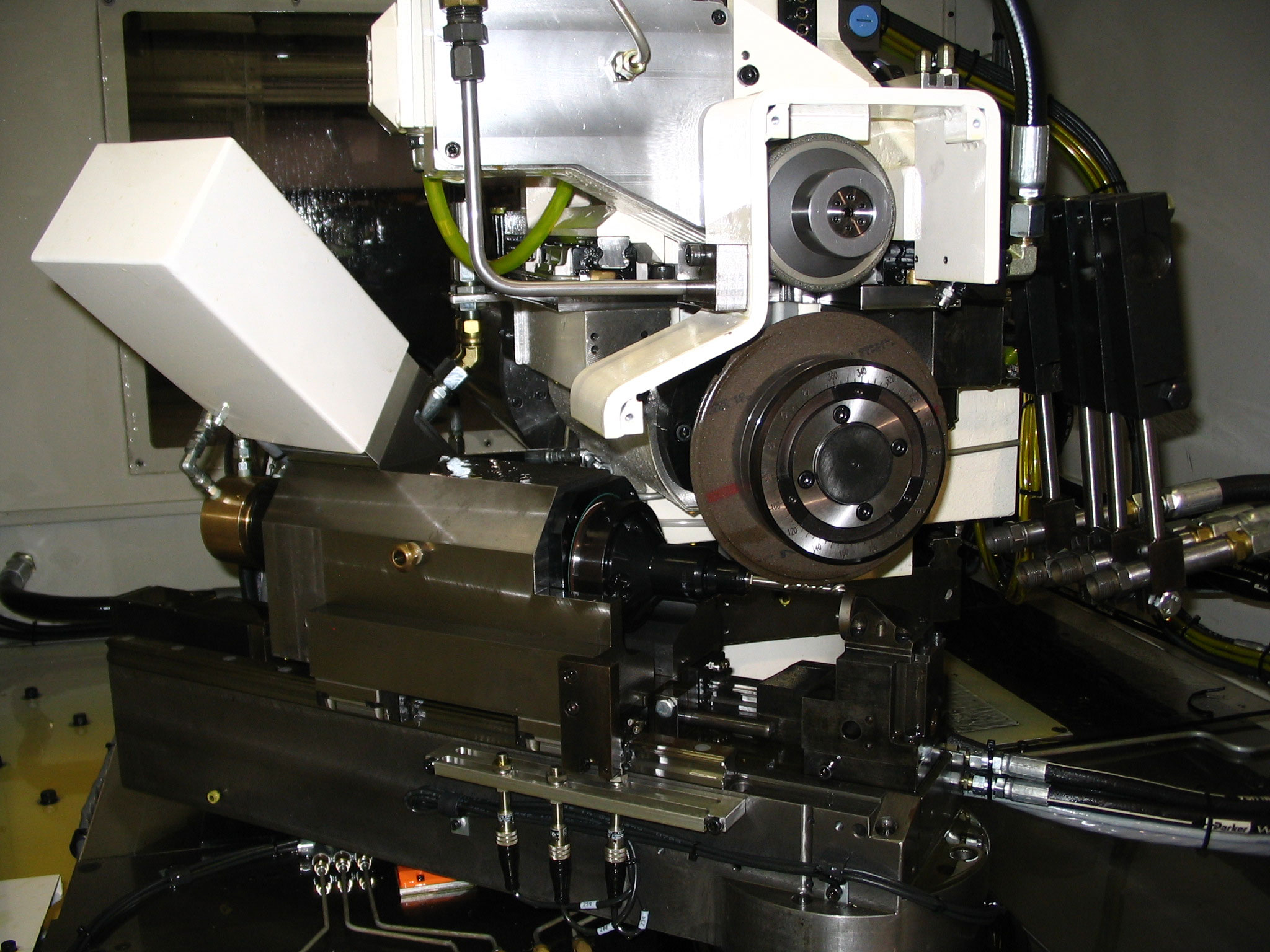

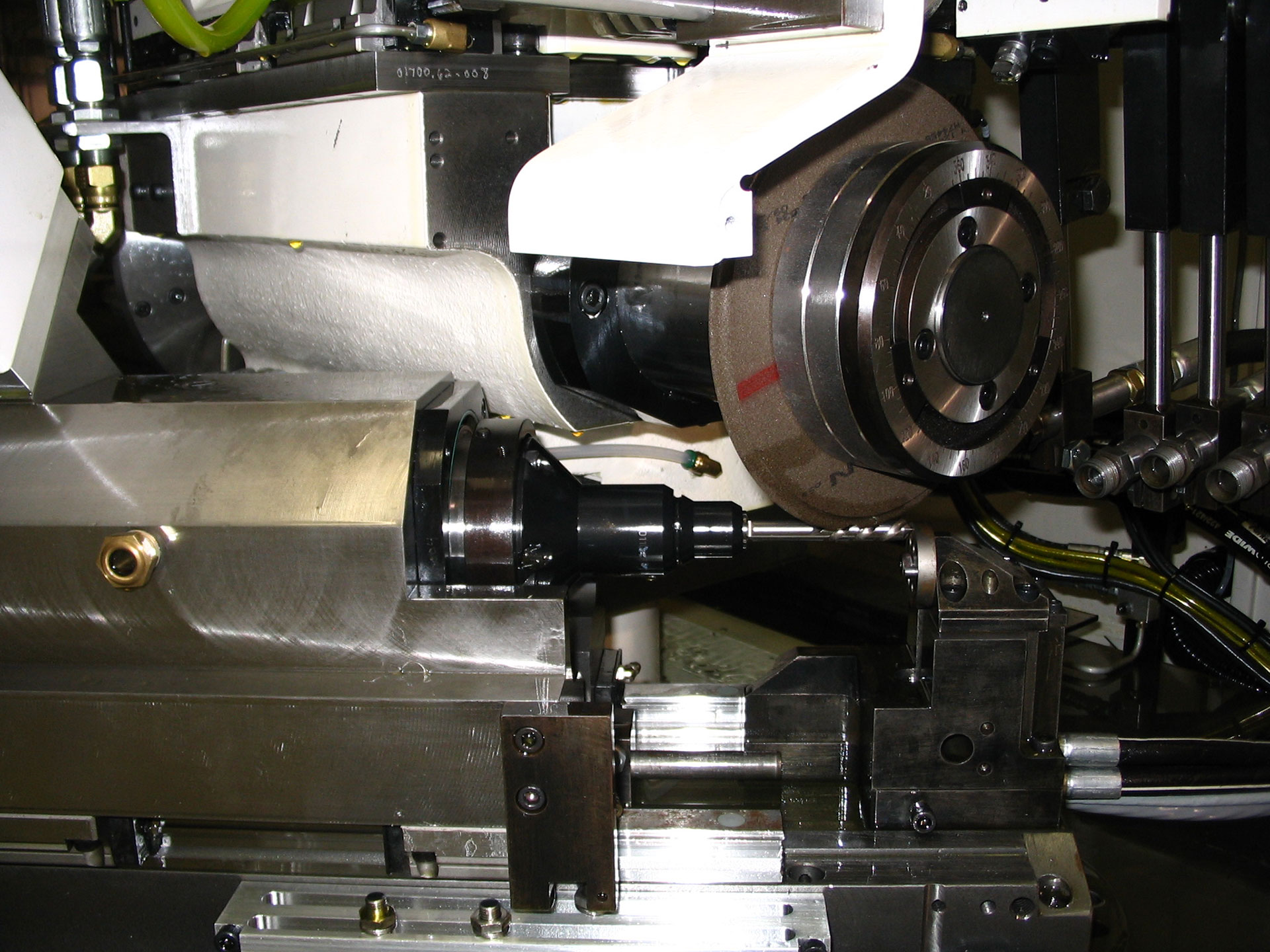

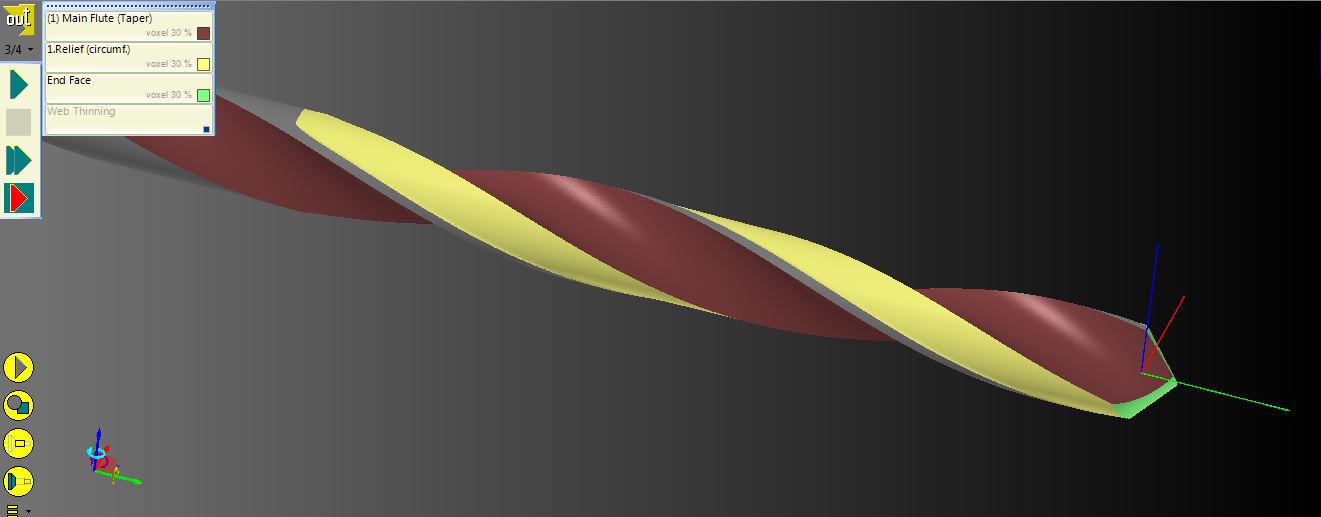

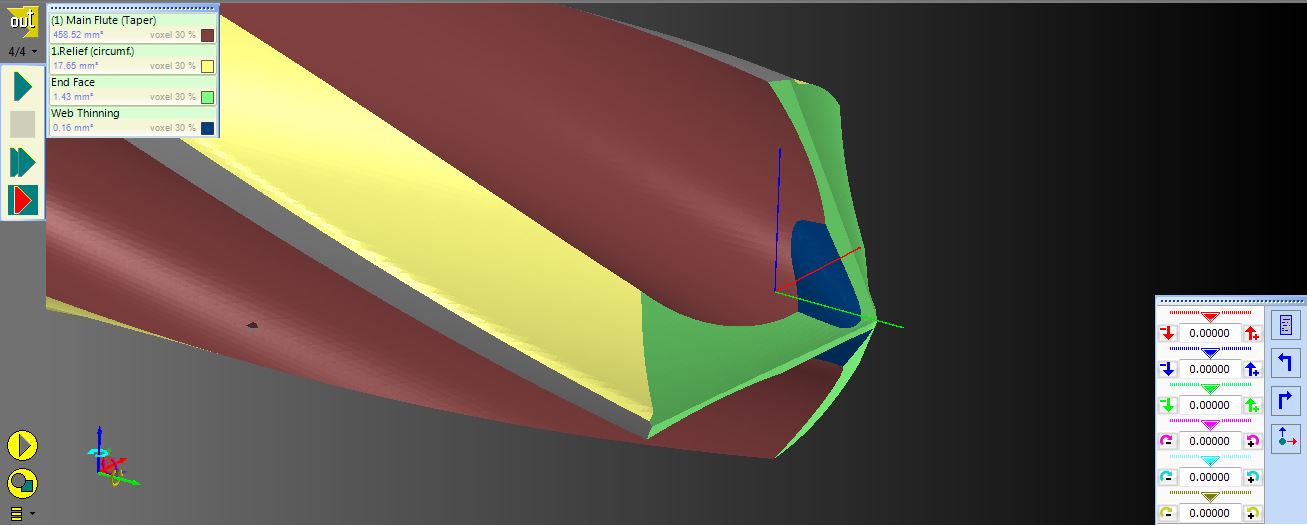

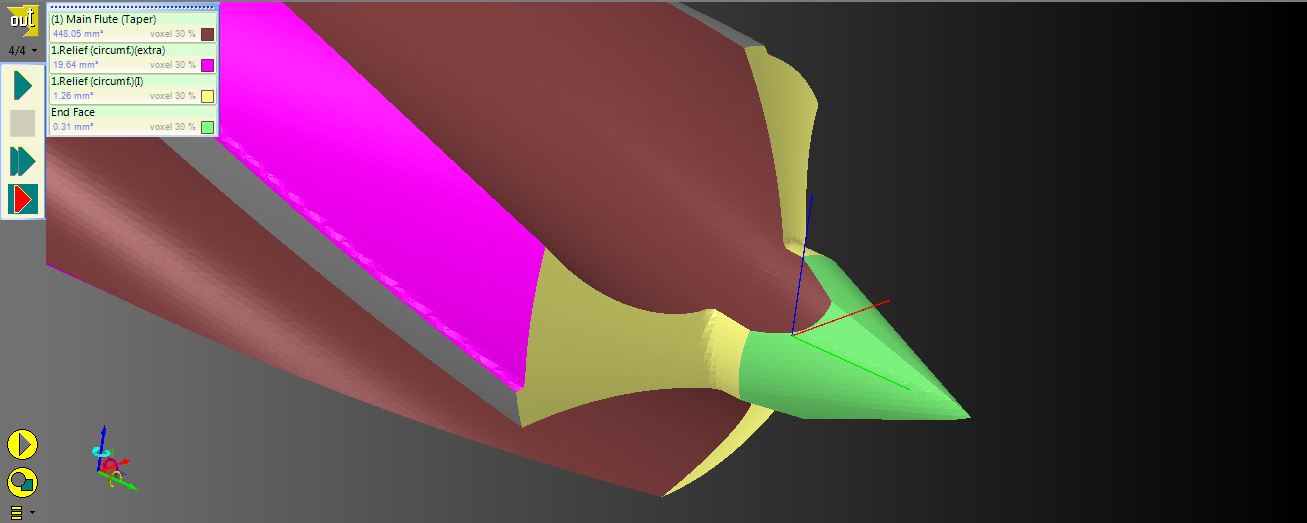

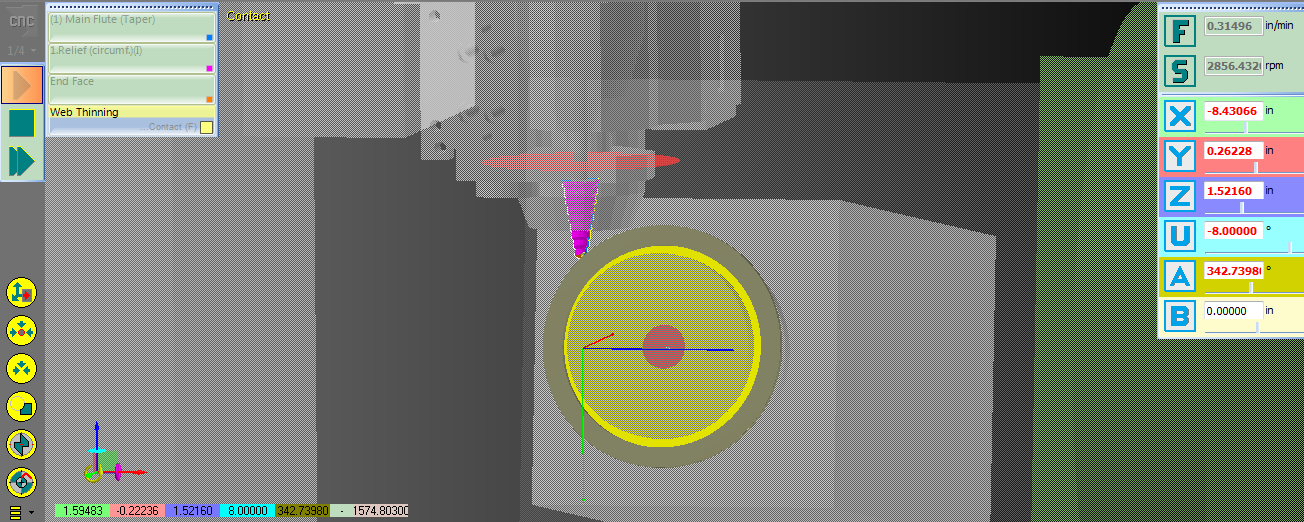

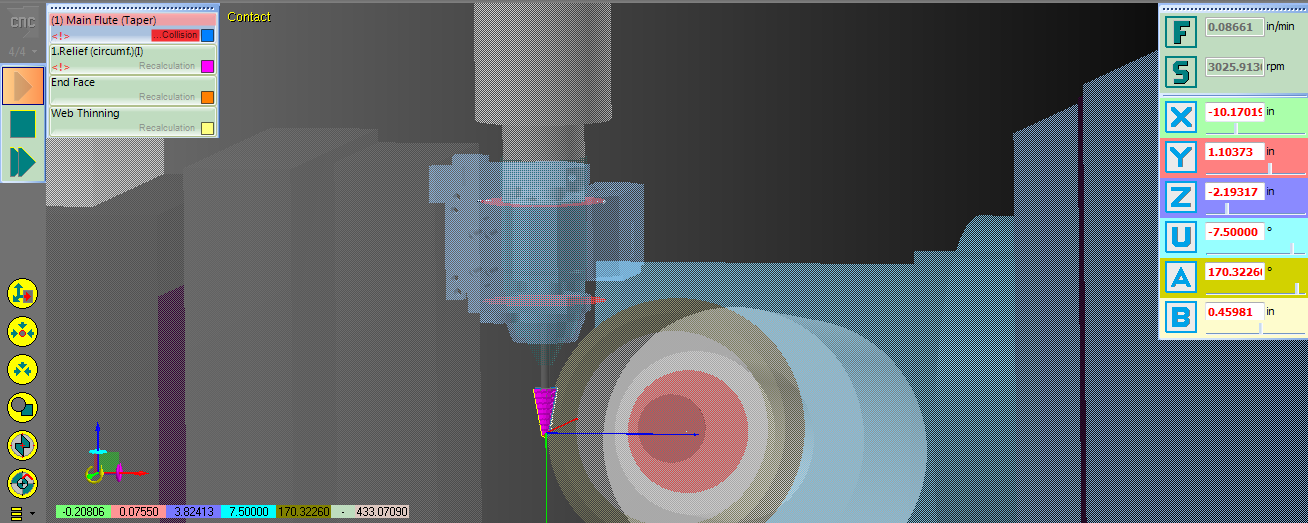

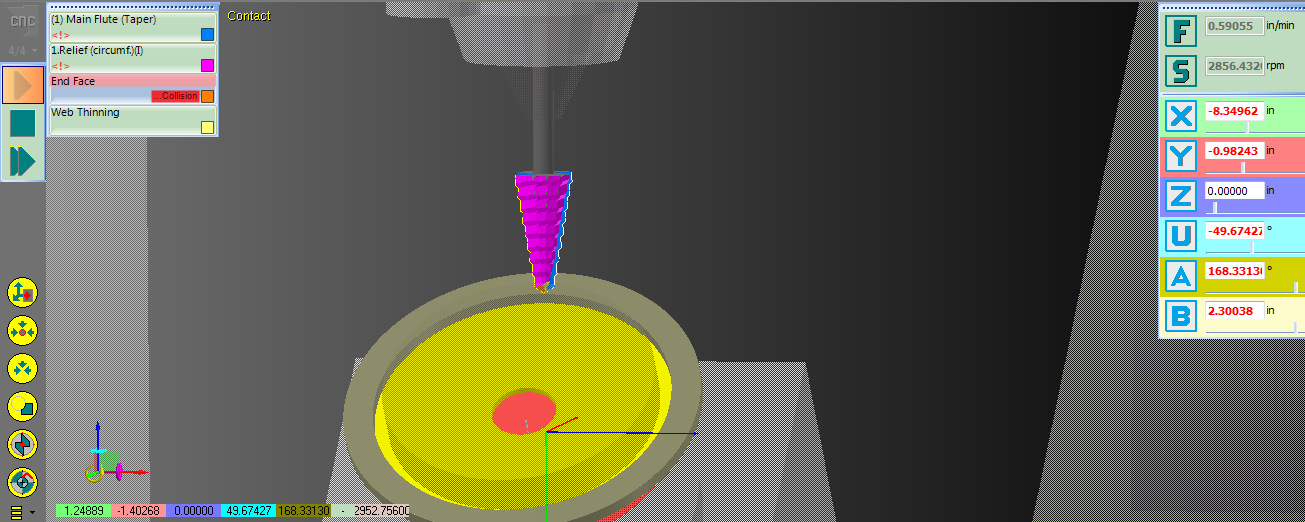

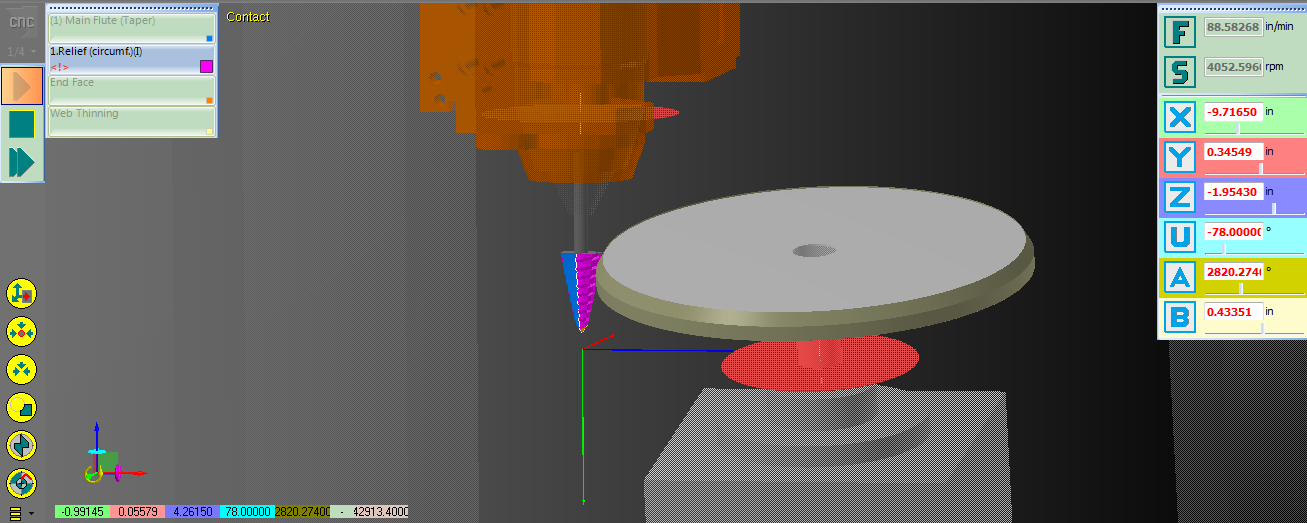

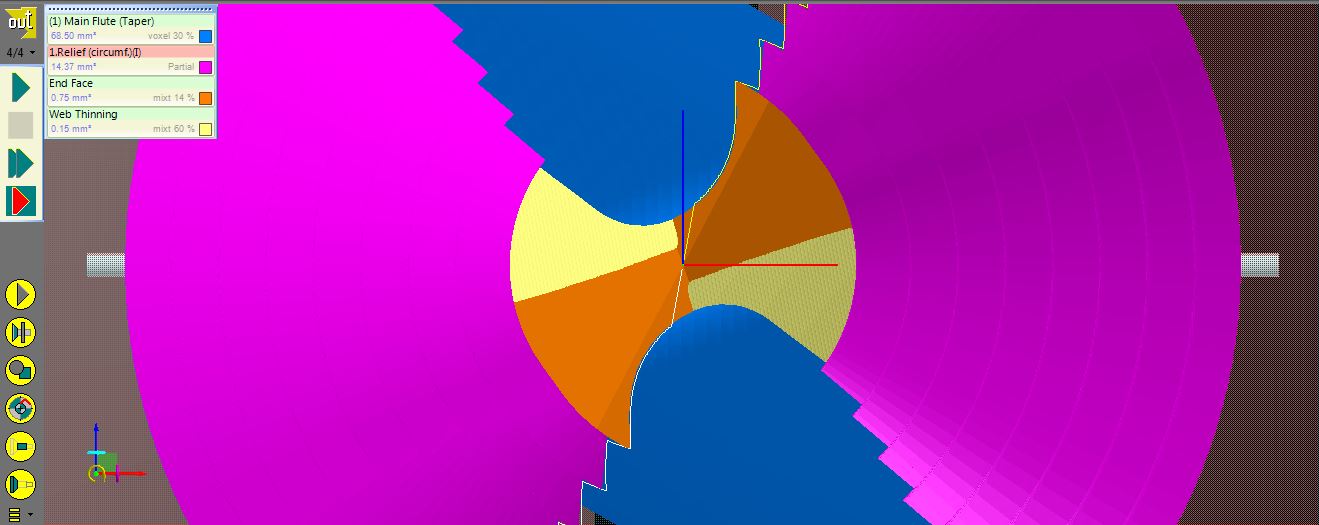

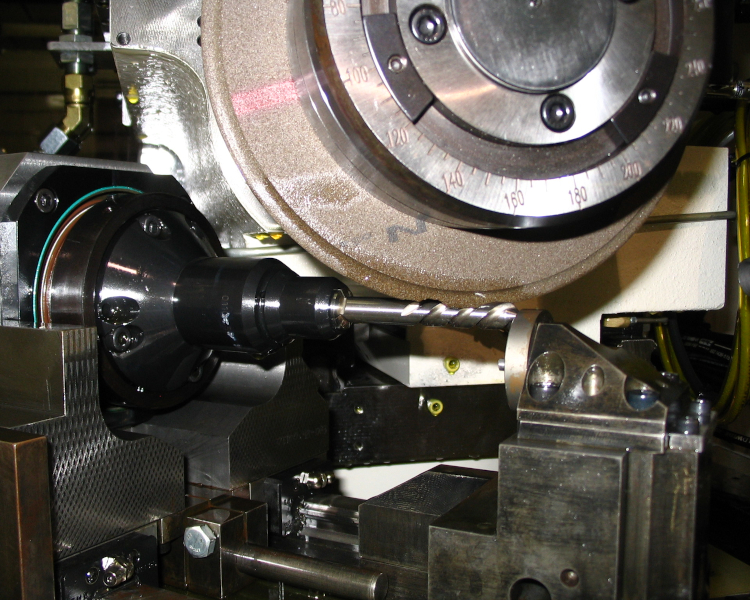

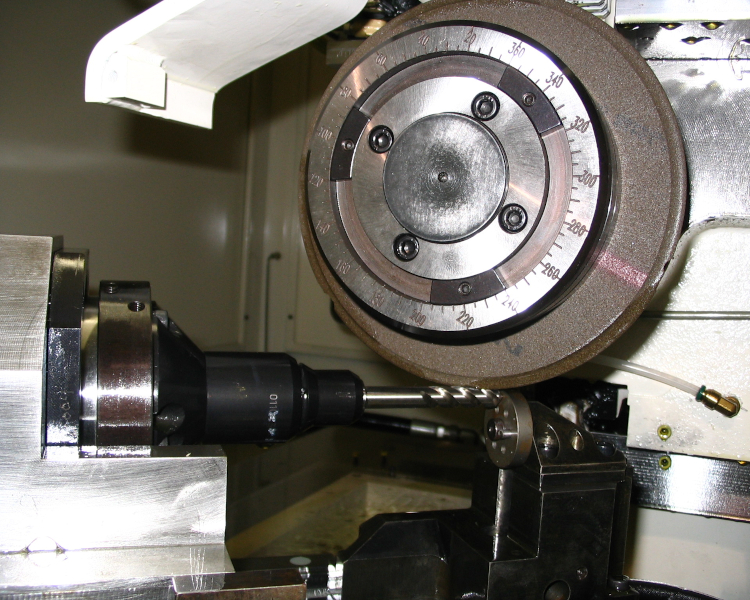

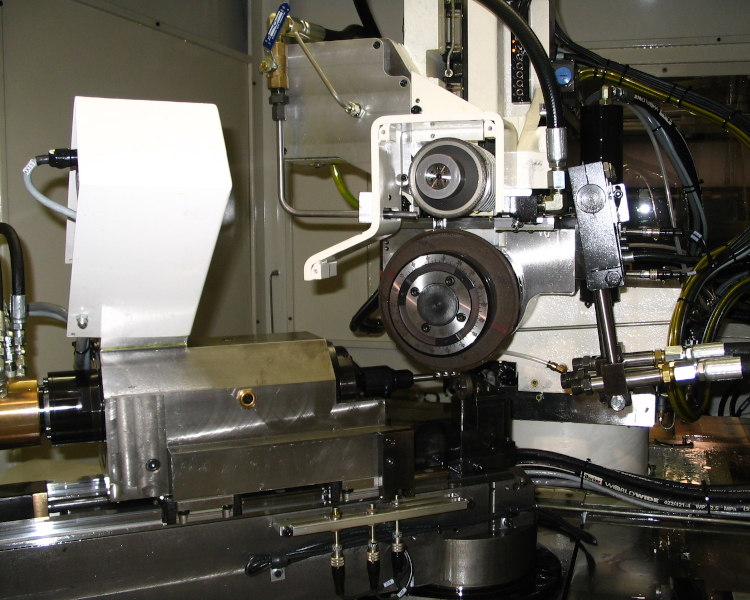

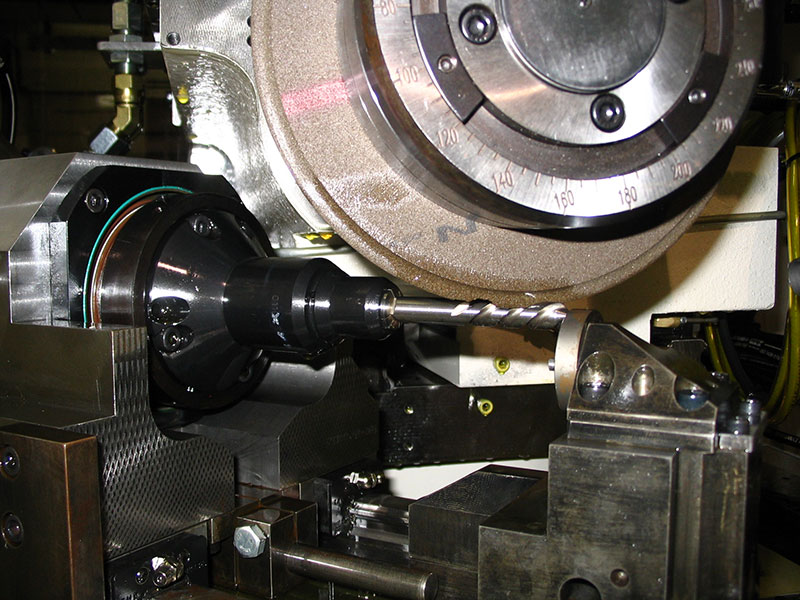

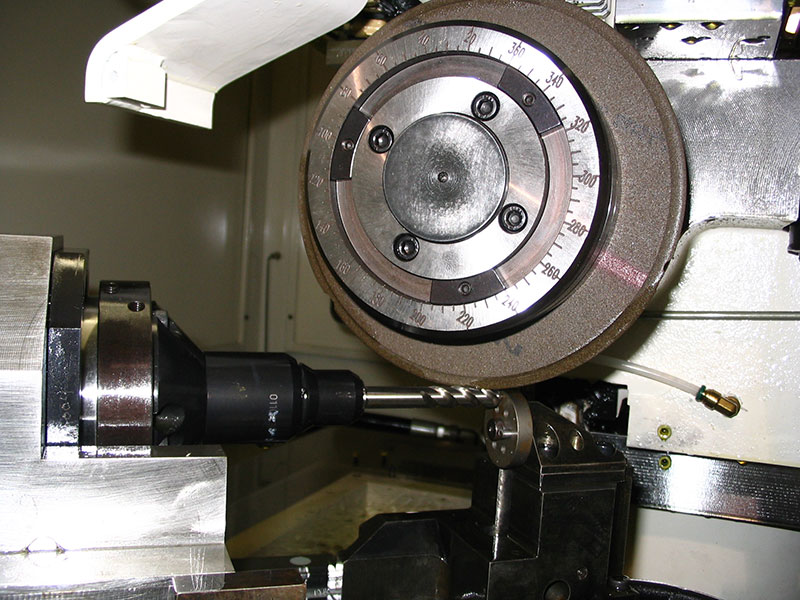

ITM’s UFGG is a high production flute grinding machine with a heavy welded and stress-relieved base, grinding spiral and straight flute, fast helix, or gun-nose in one clamping. The workhead (A axis), rotary table (U axis), cross slide (X axis),

longitudinal slide (Y axis) and vertical supported column (Z axis) are CNC controlled. The X, Y and Z axes have an incremental movement of 0.00004in with a rapid traverse rate up to 98.4in/min. The resolution of the A, and U axes is 0.001°. The inprocess dresser uses 2 CNC axes, vertical slide (V axis) and horizontal slide (W axis).

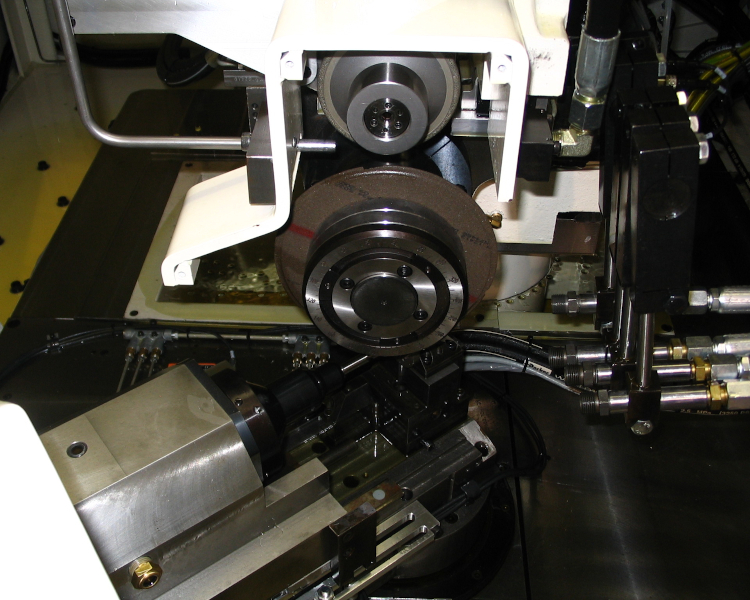

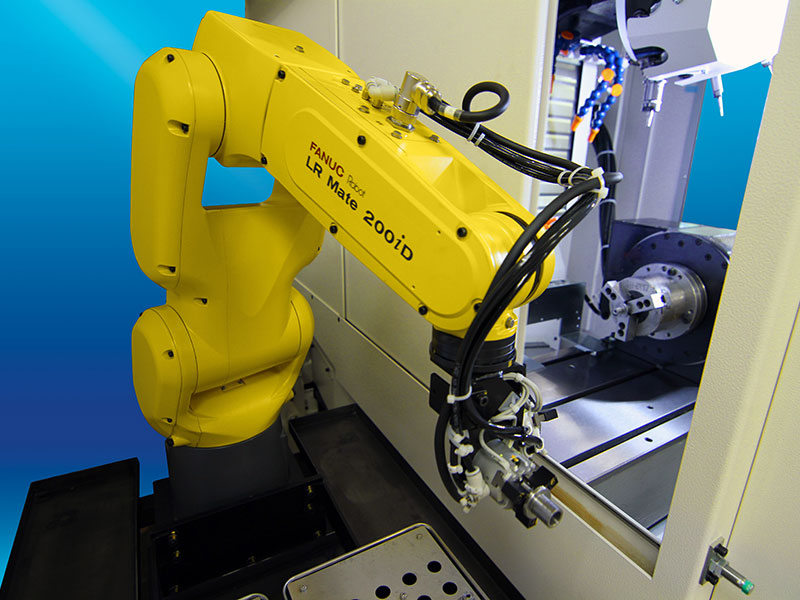

With 7 CNC controlled axes plus a 2 axes CNC loader or 6 axes Fanuc™ robot loader, setup time is usually 25 minutes or less, making this machine economical for both large and small production runs. Due to the rigidity of the machine, along with programming capability, standard resinoid, plated CBN, dress-able CBN or diamond coated wheels can be utilized. When the correct grinding wheels are used, the machine can be operated with wheel speed up to 262ft/s.

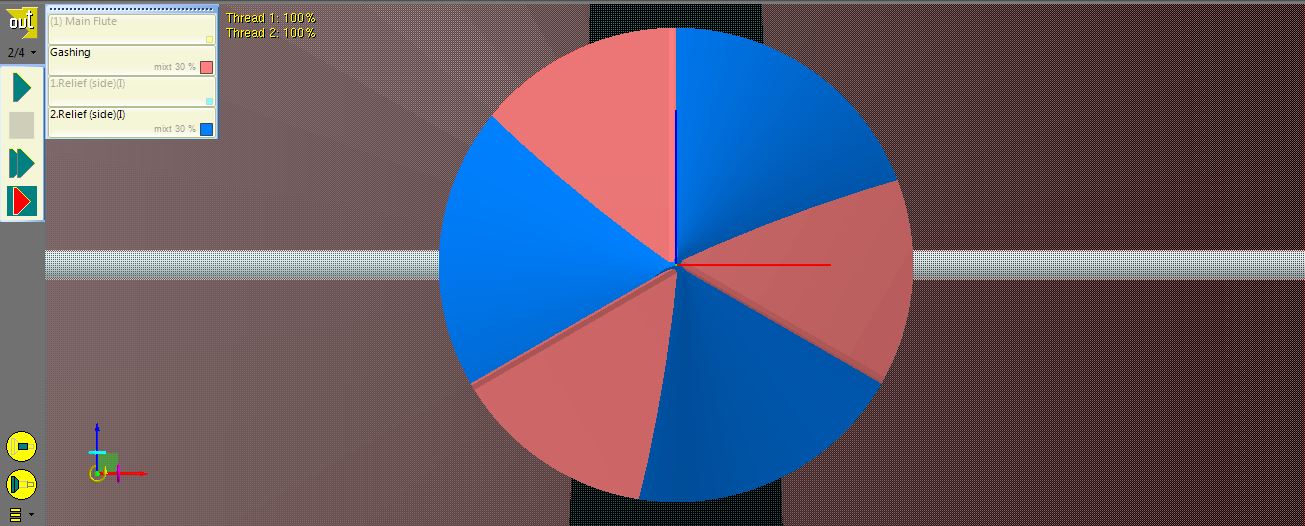

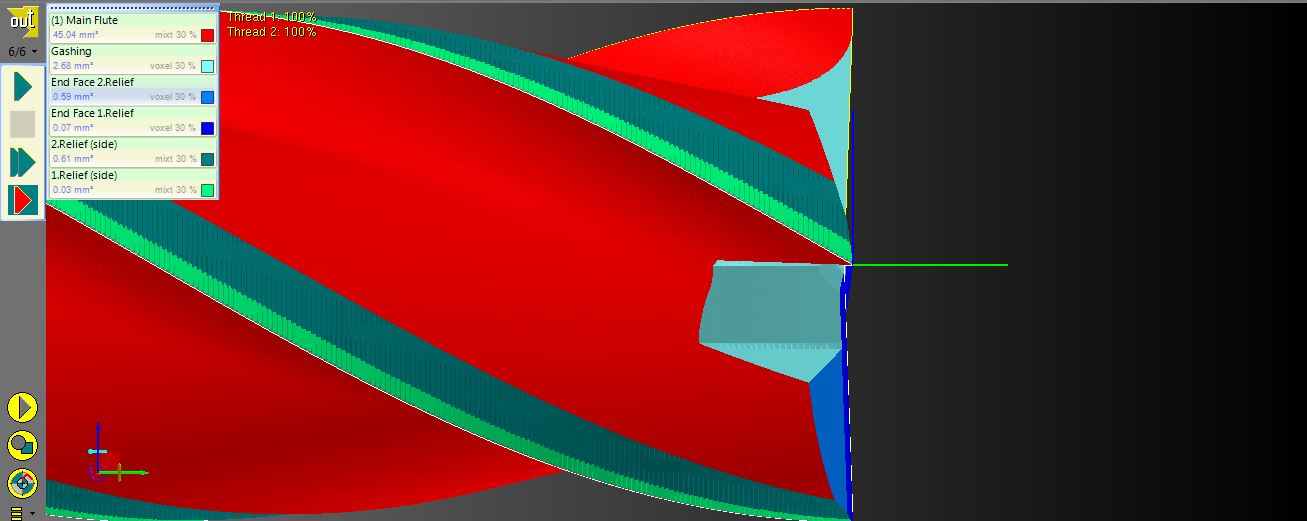

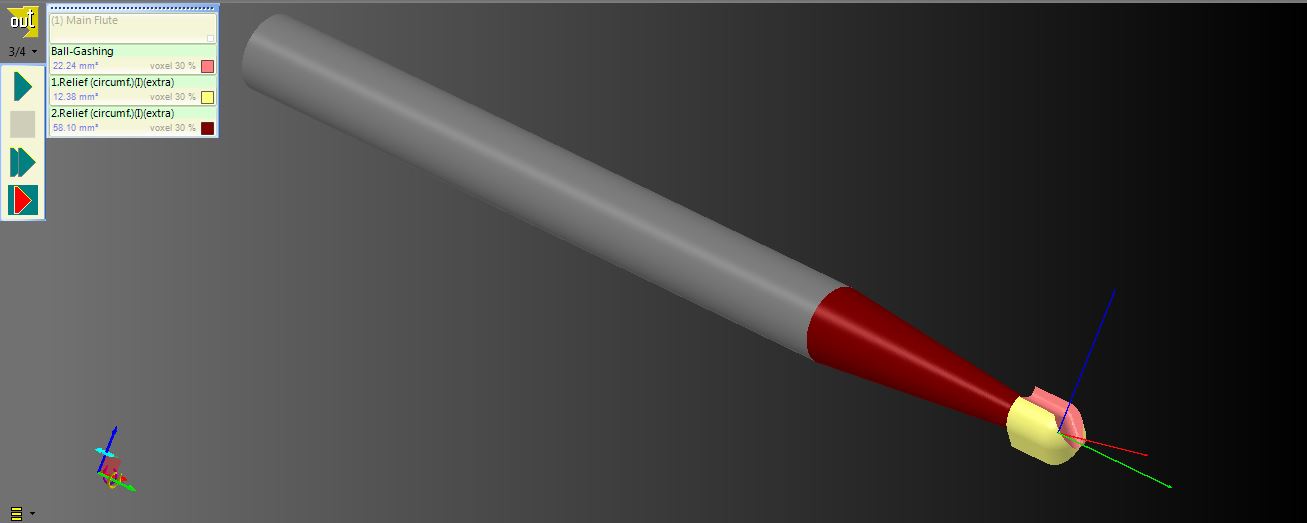

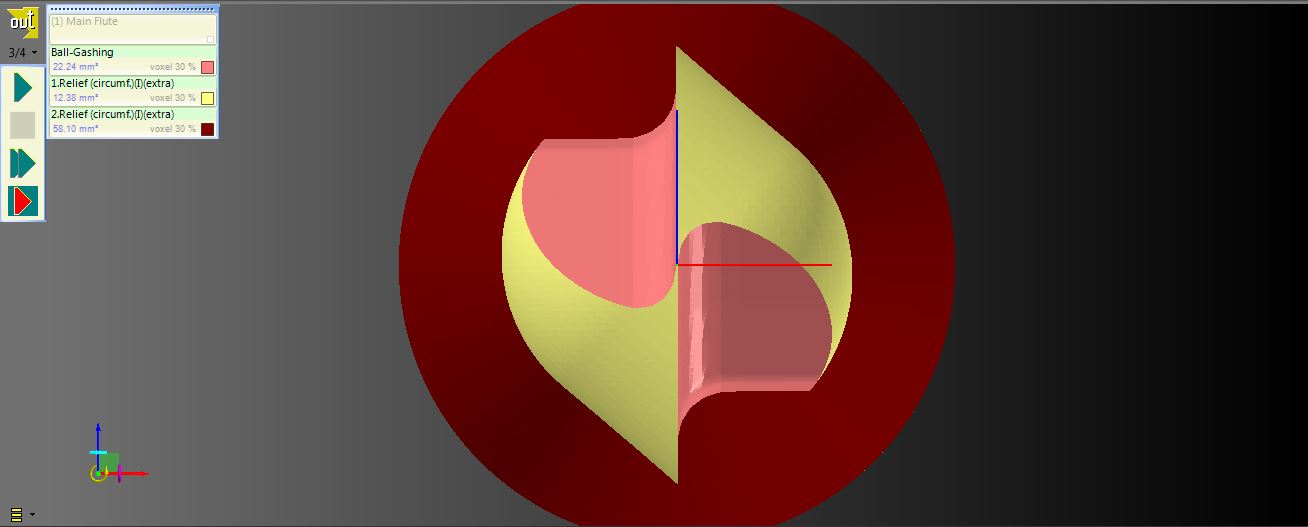

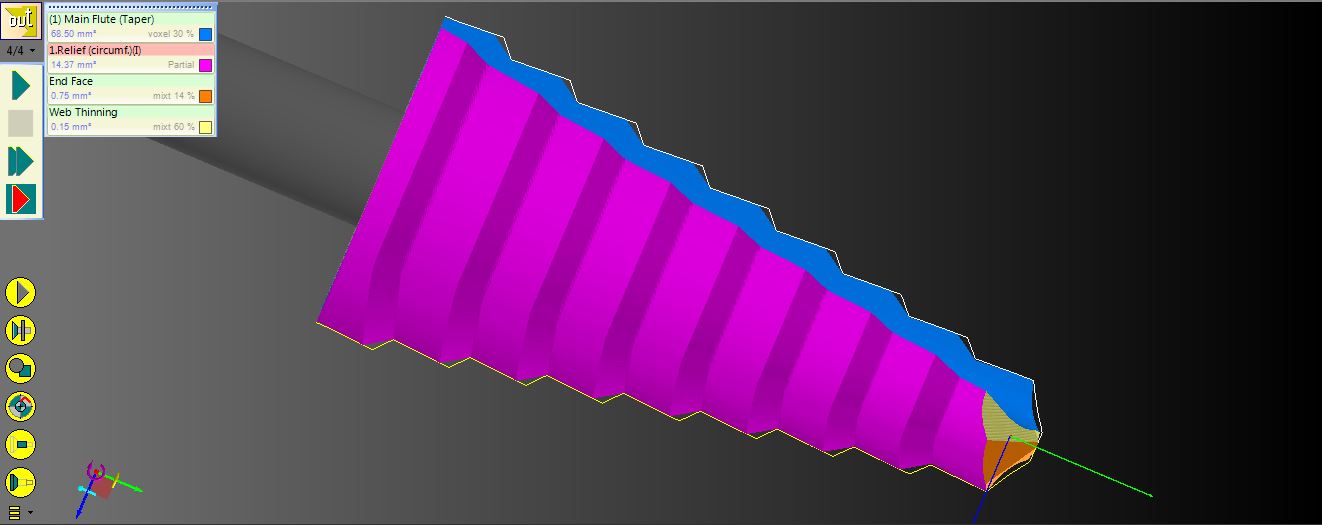

UFGG grinding straight and spiral flutes

Fanuc robot loads/unloads for 24/7 non-stop production

HOW IT WORKS

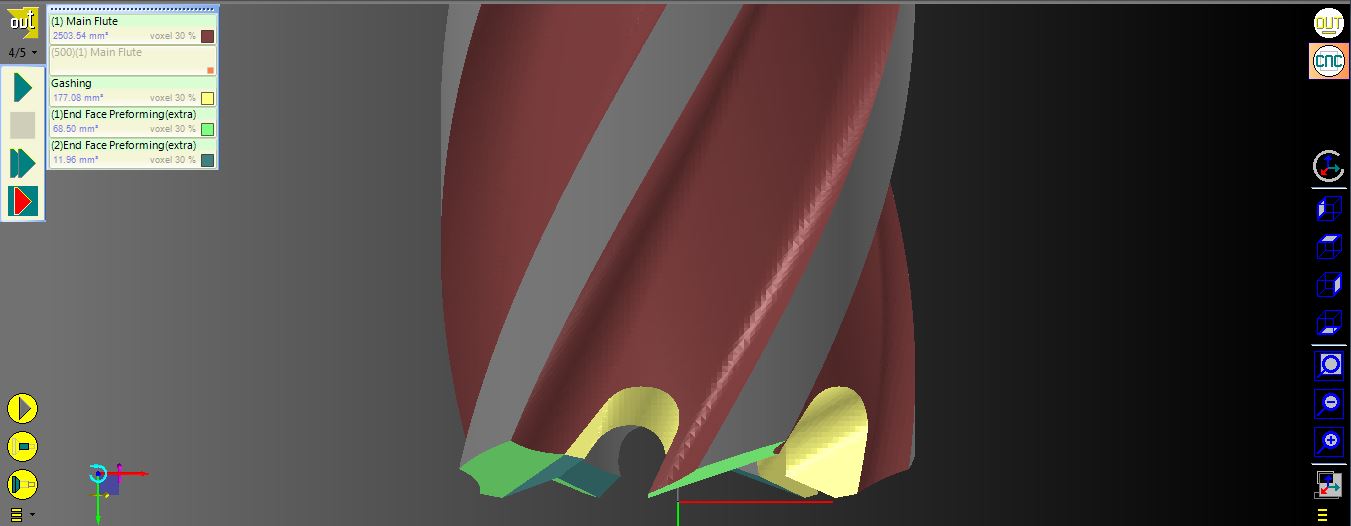

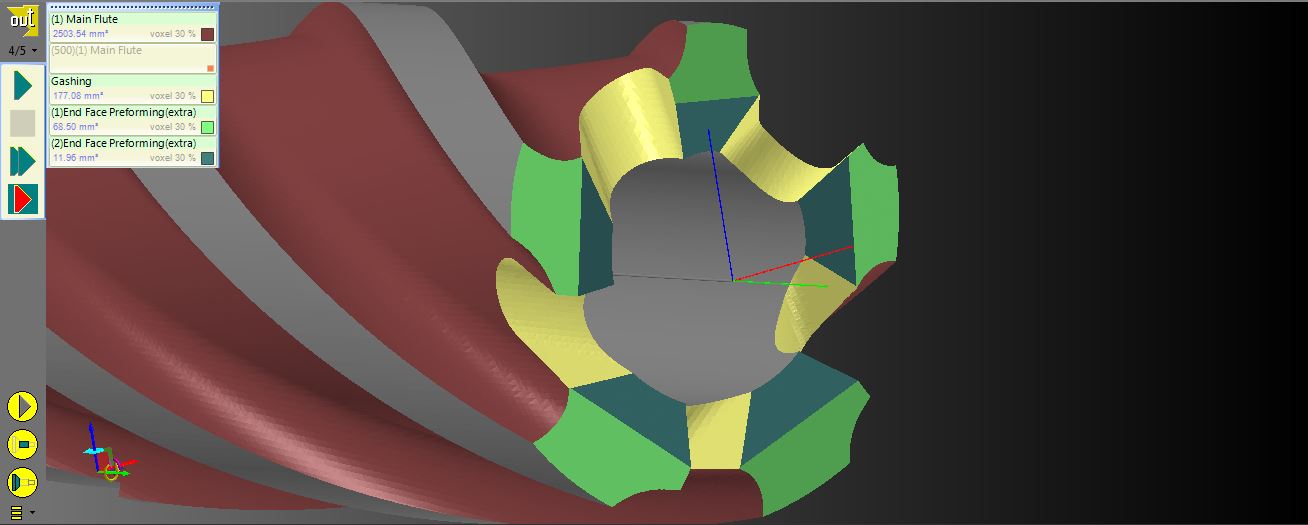

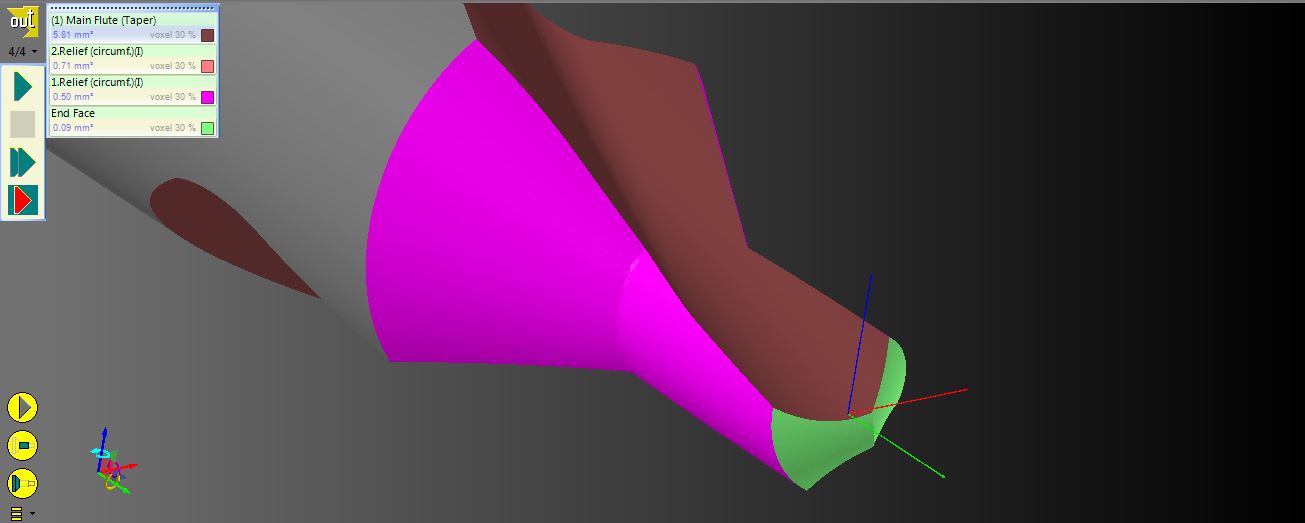

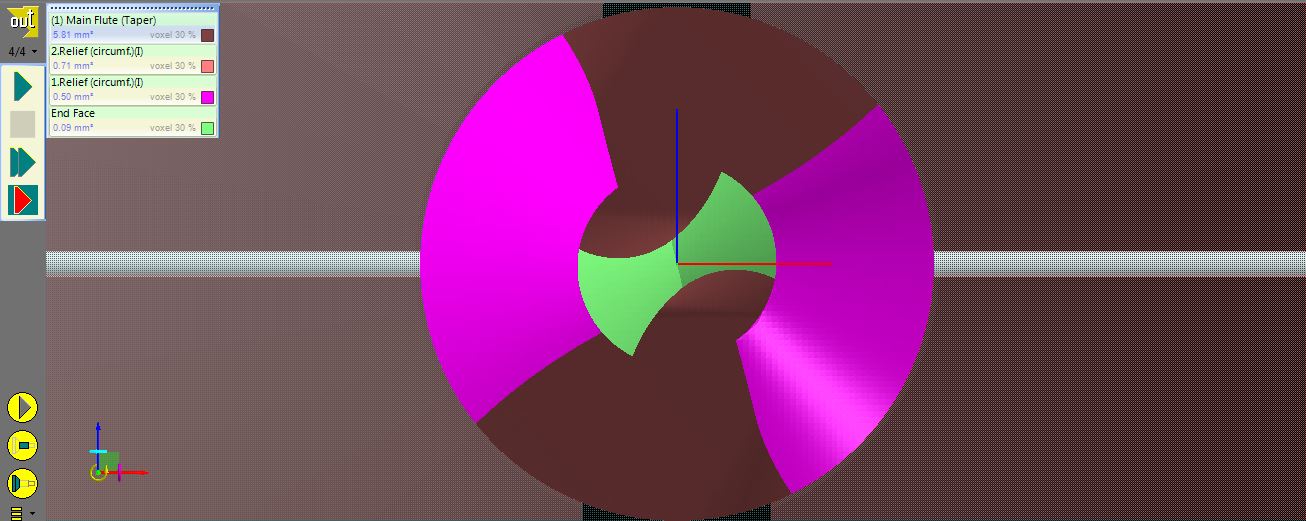

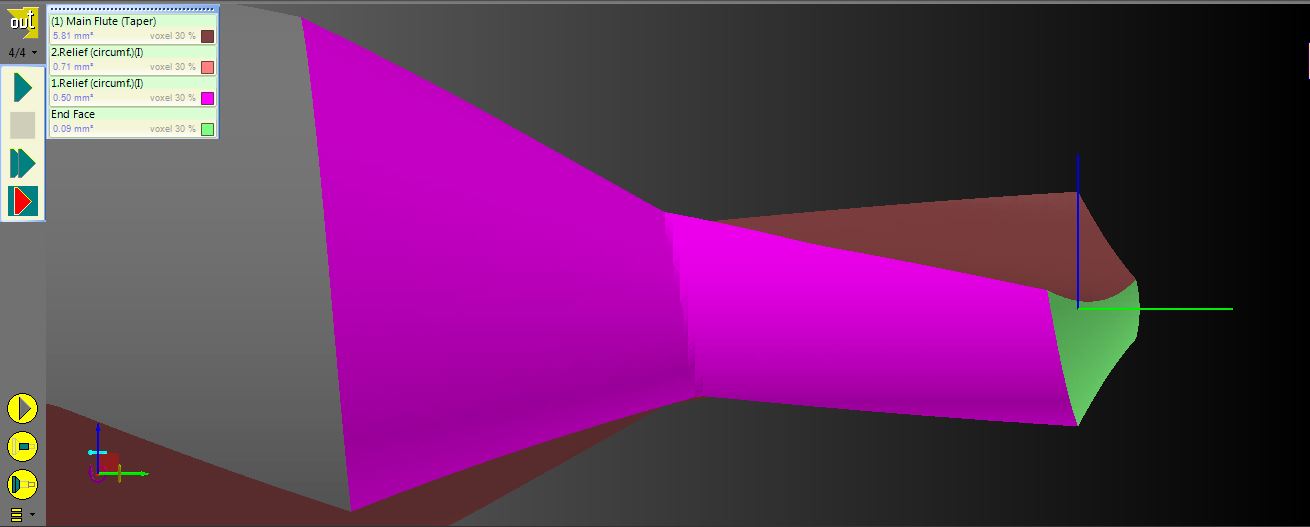

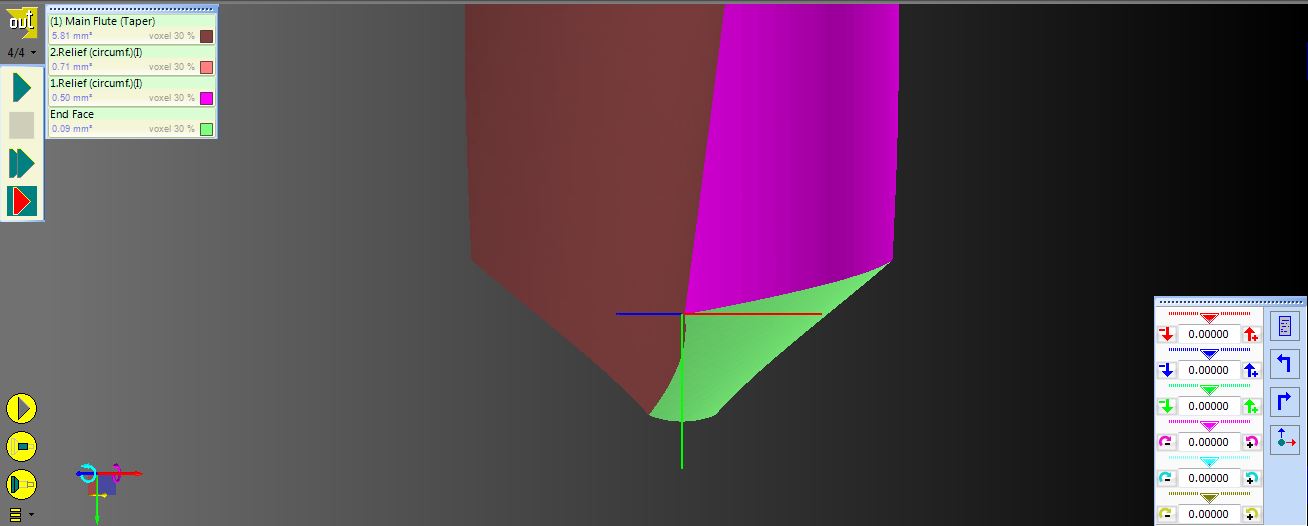

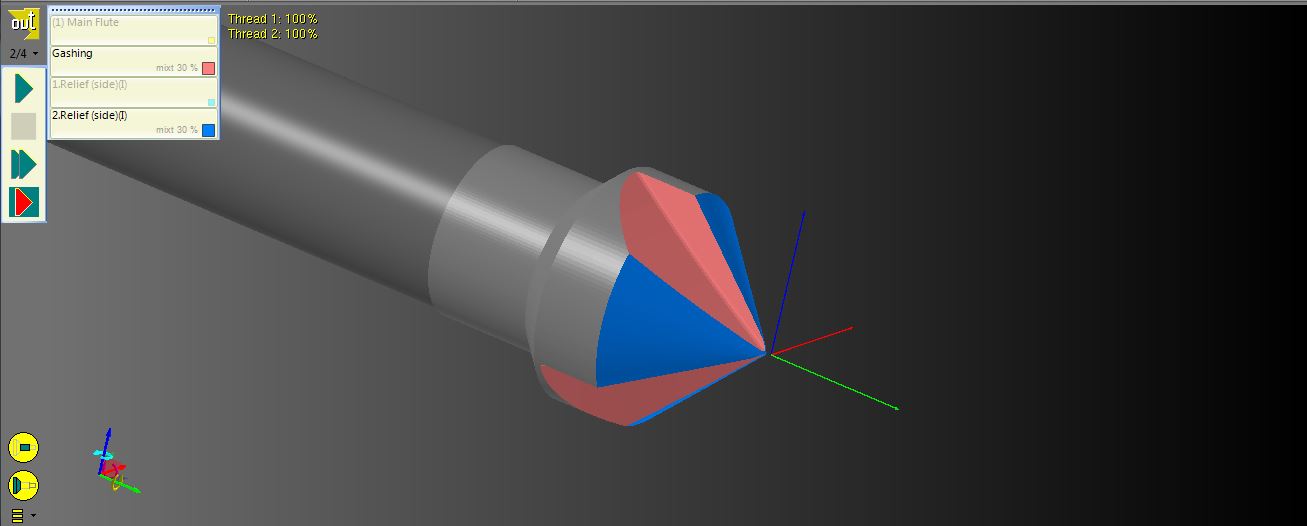

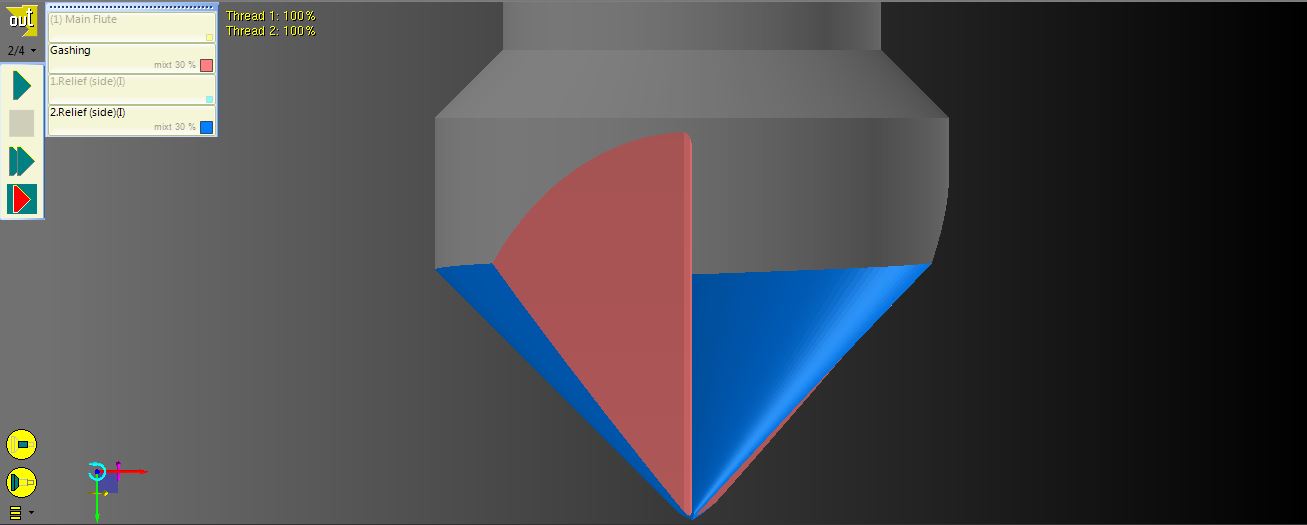

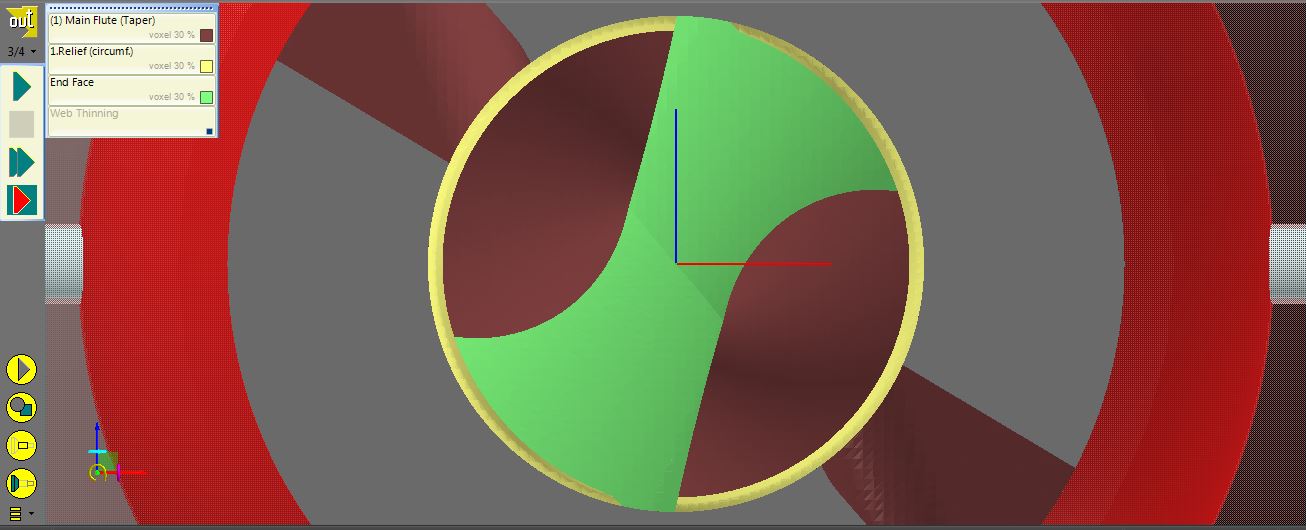

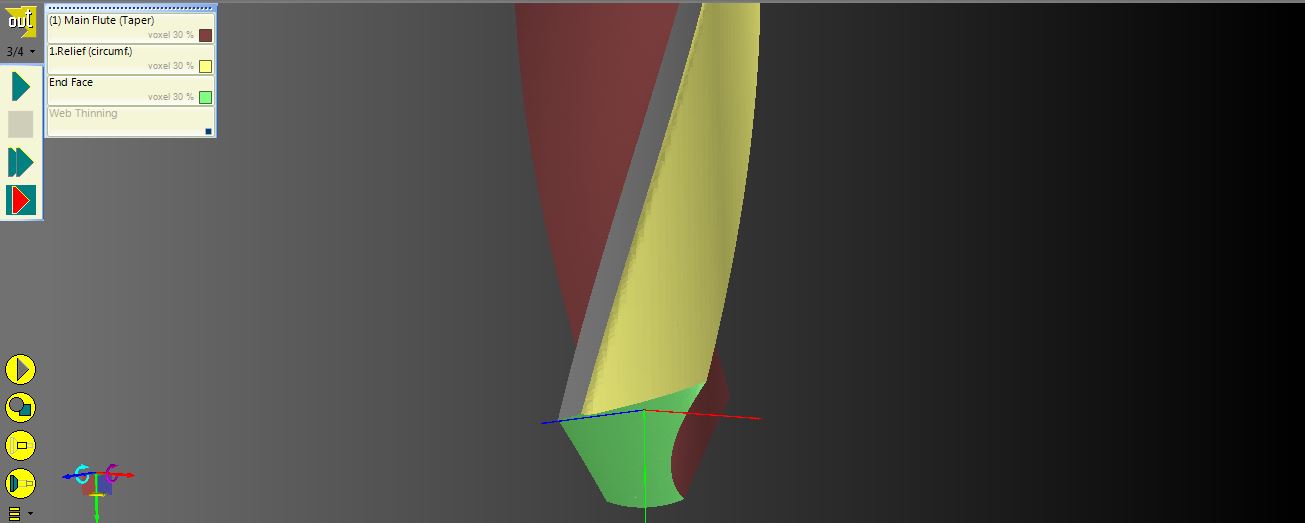

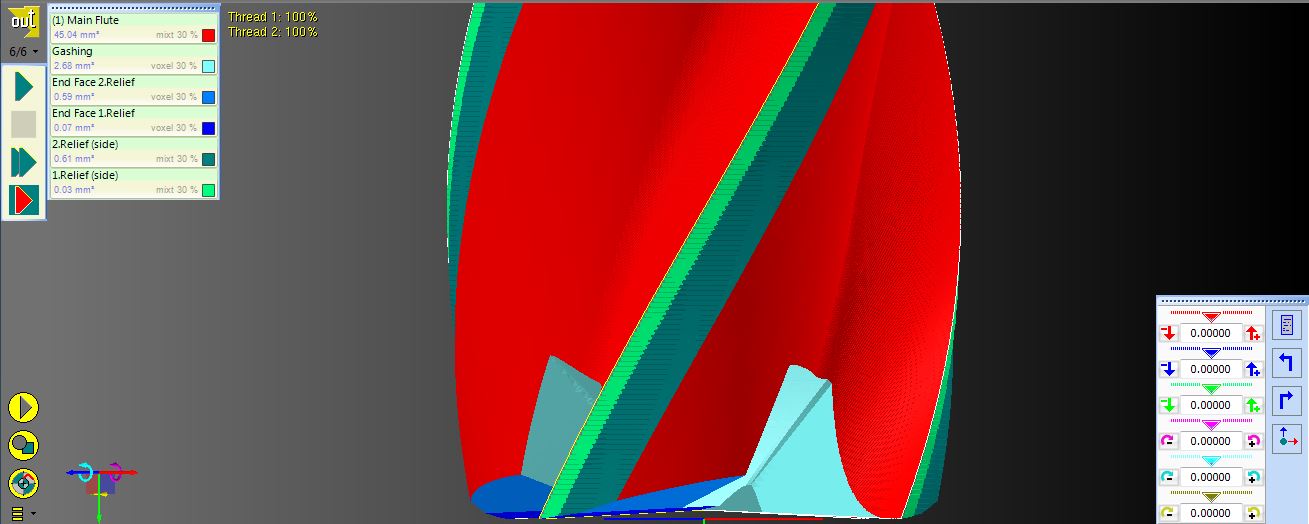

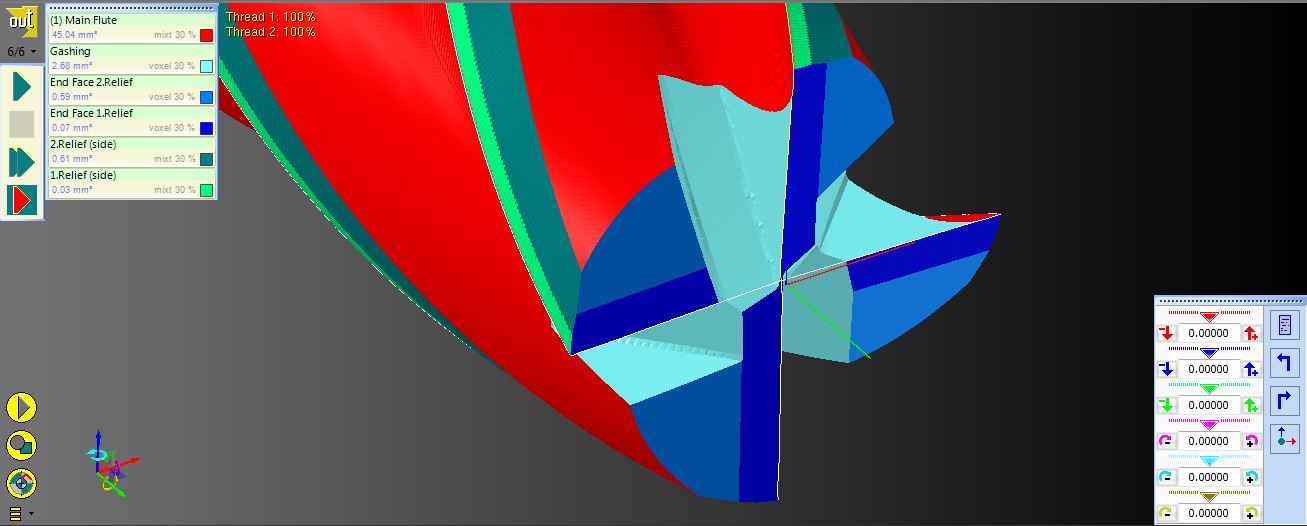

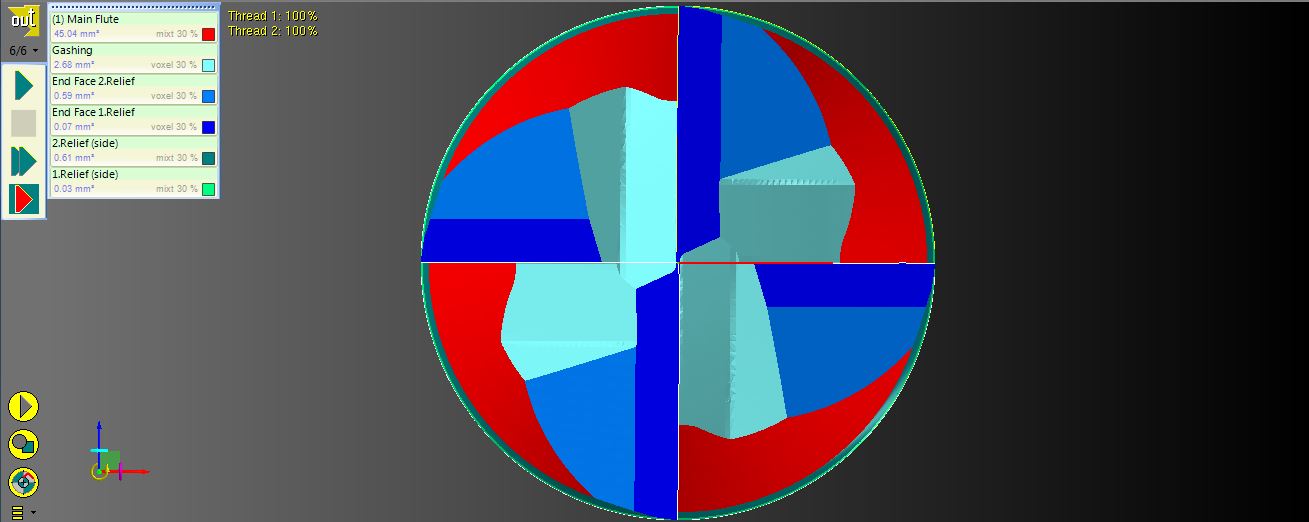

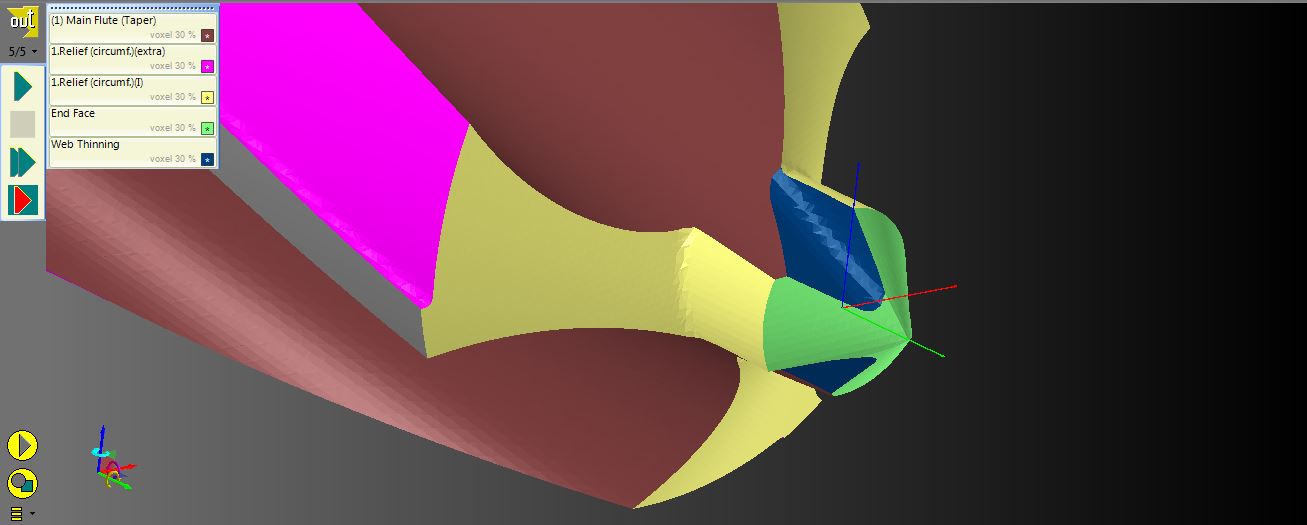

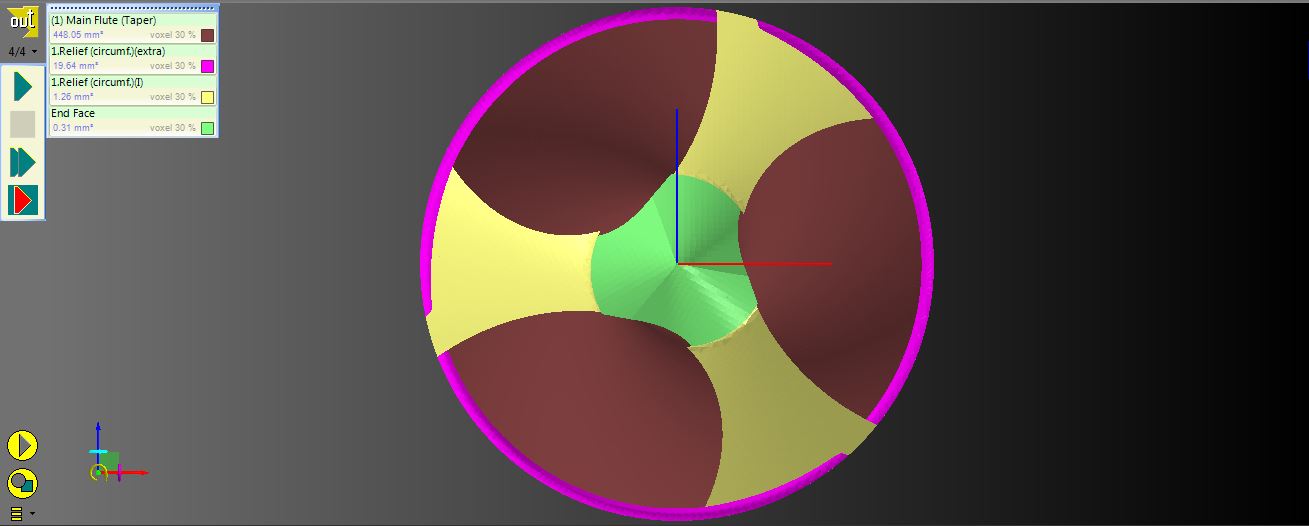

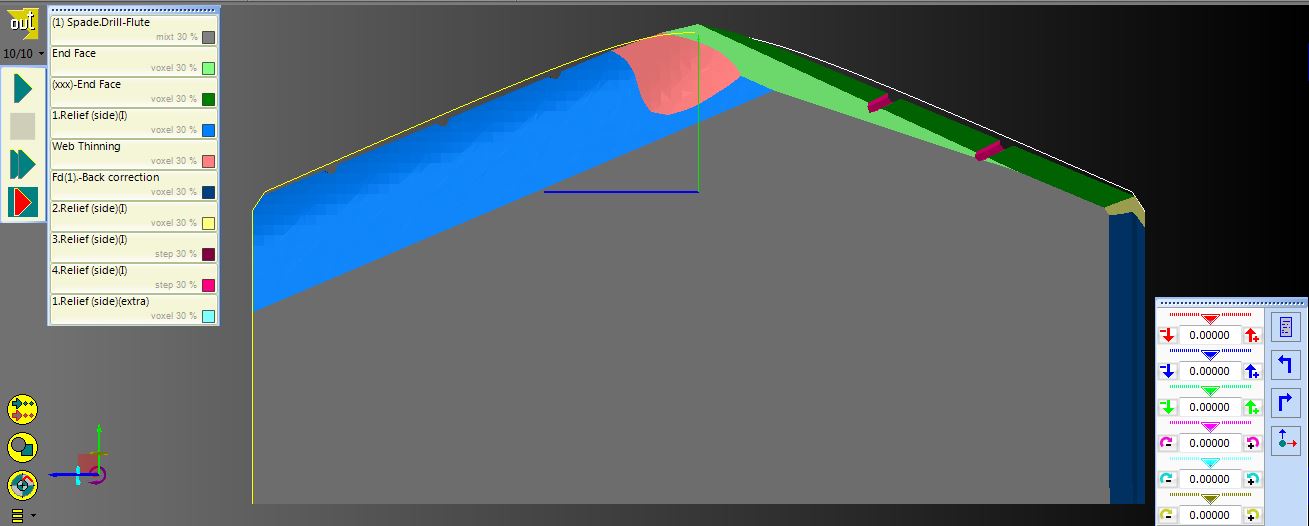

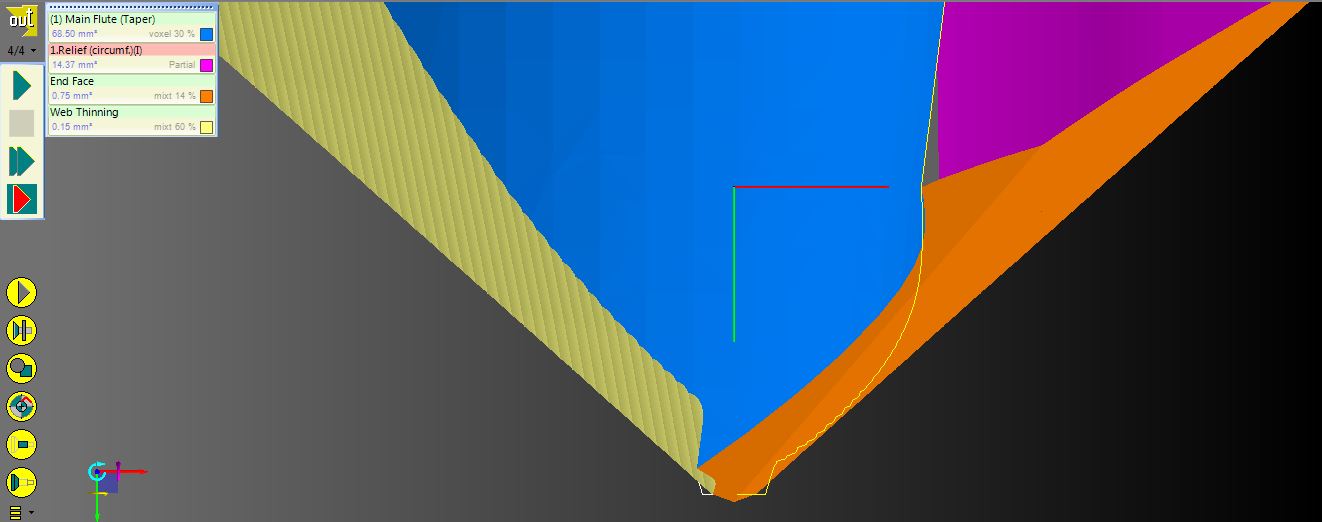

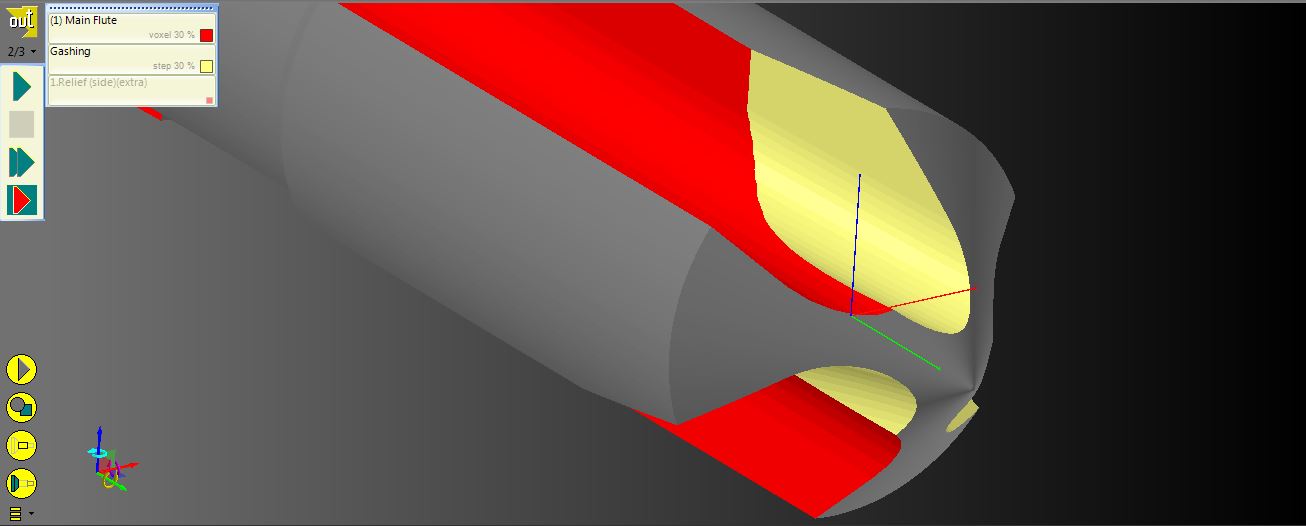

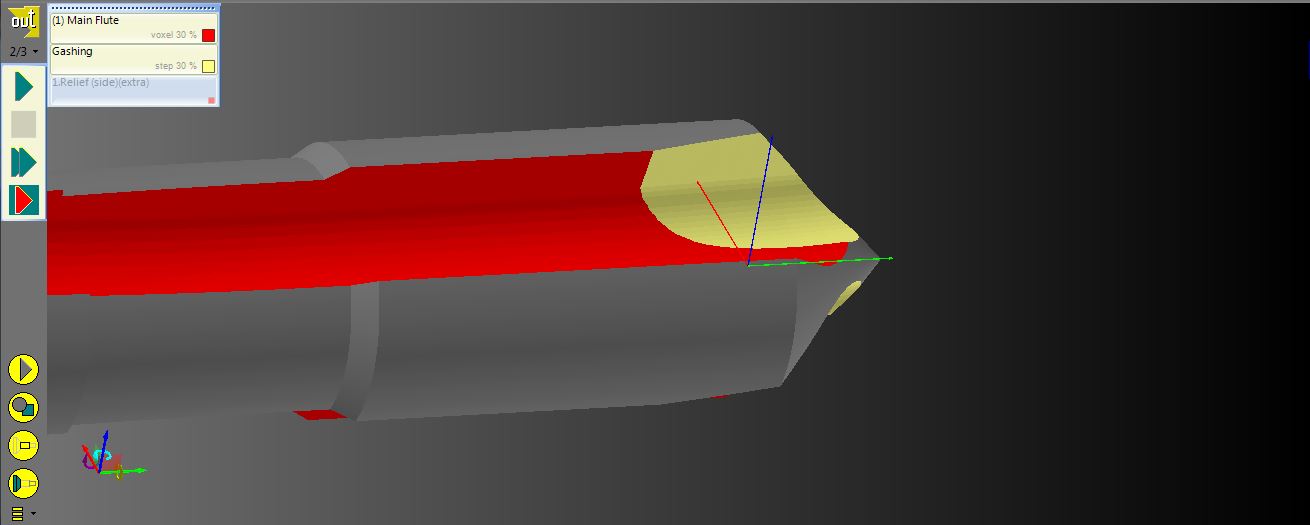

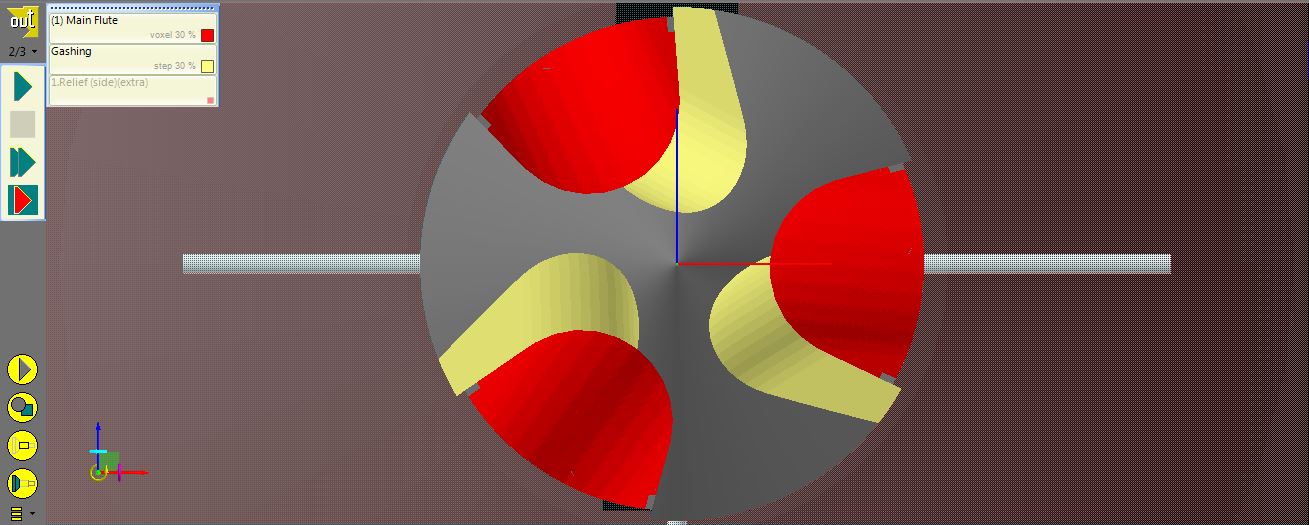

The tool blanks are loaded either manually or with the optional automatic loader and held in collet and tailstock center for grinding. The U axis then rotates to the desired helix angle and the grinding cycle begins. The grinding process uses X, Y and Z axes interpolation while rotating the A axis workhead to generate desired spiral fluting geometry. For straight flutes, the U axis remains in the “zero” position and the A axis is used for indexing. When the fluting is completed, the dressing cycle begins, re-truing the wheels for the next part if necessary. The frequency of the dressing cycle can be selected. Dressing is only possible for standard and CBN wheels. This machine can be set-up to grind straight flutes, straight flutes and gunnose, or spiral flutes in one clamping. Using the Fanuc™ robot loader, it is possible to run the machine unattended as long as good grinding technology is used, allowing for long periods of production without operator involvement.

For further information regarding ITM’s Flute Grinders, please contact us at 386-585-8166.

More than 70 UFGGs at Sandvik

UFGG is capable of online dressing while loading

ULTRA PRECISION, HIGH PRODUCTIVITY & SHORT CYCLE TIMES

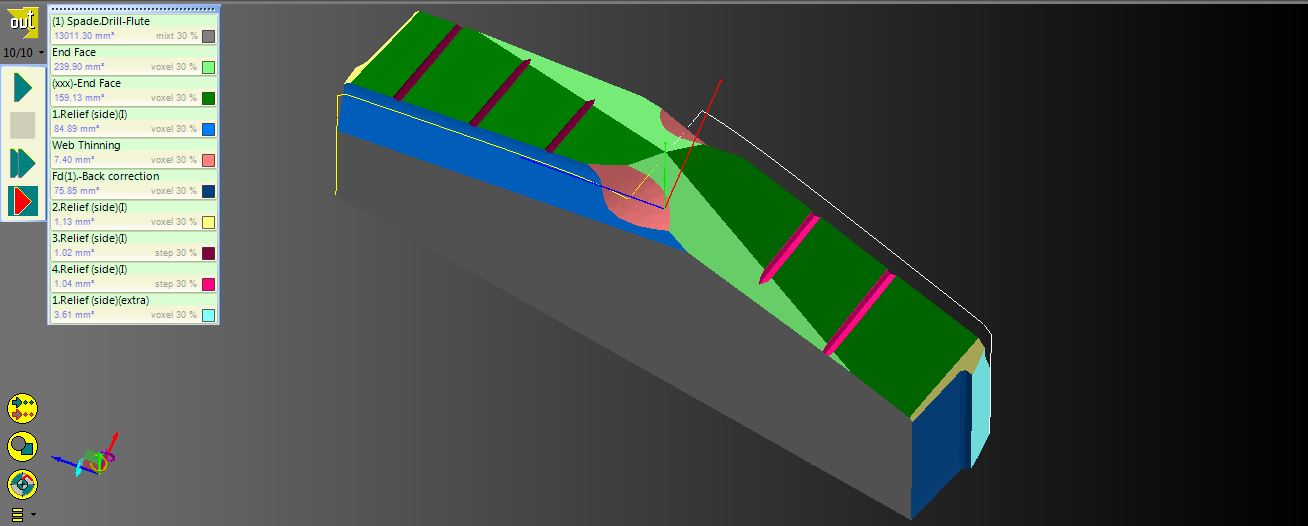

FLEXIBLE SOFTWARE, EFFICIENT & USER FRIENDLY

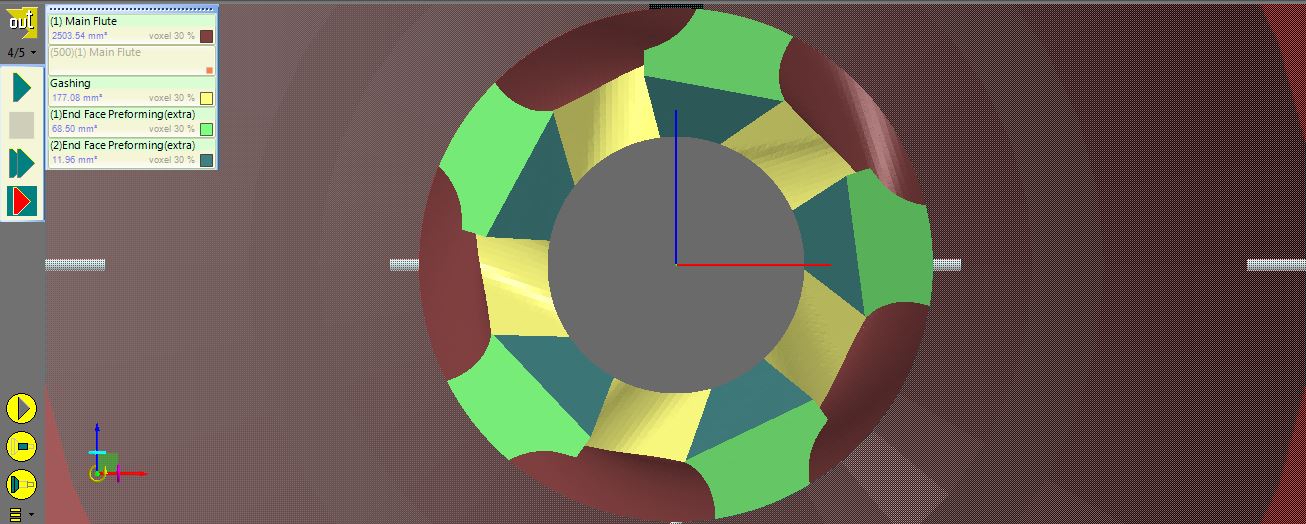

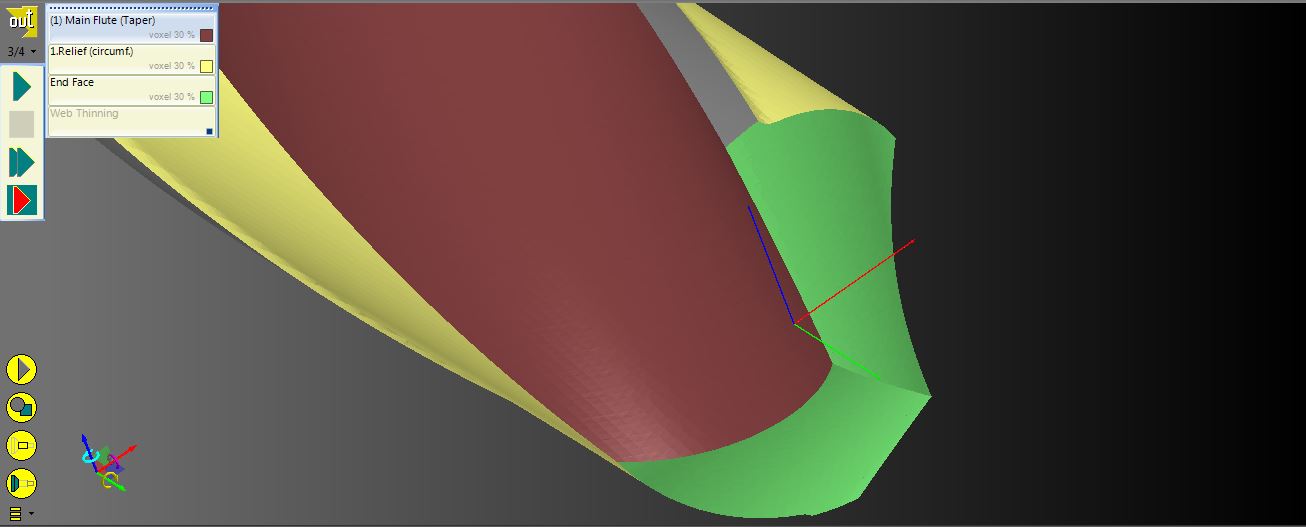

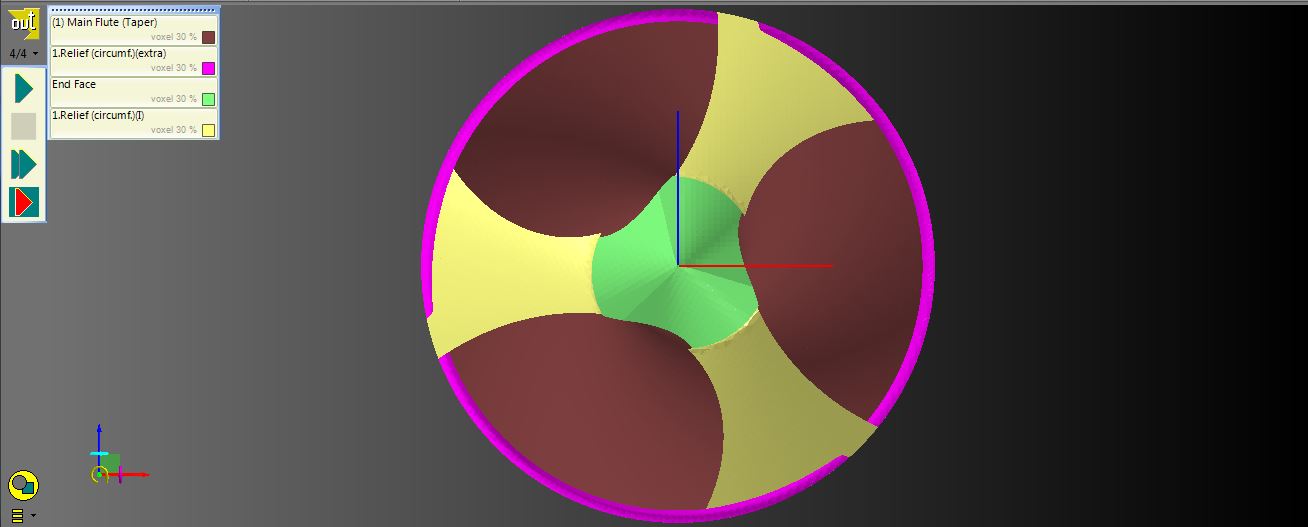

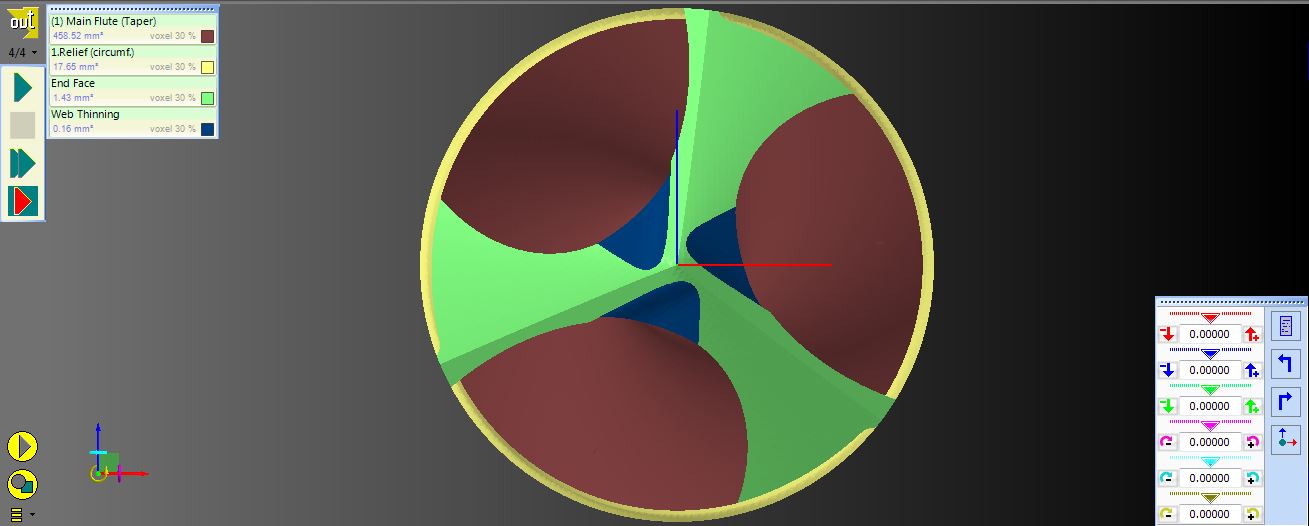

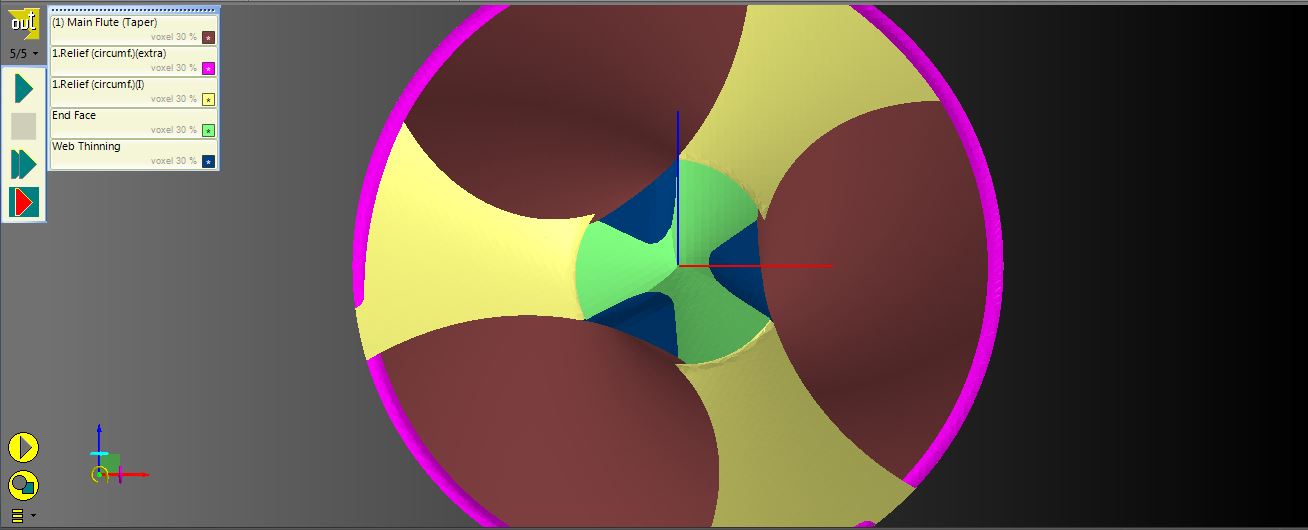

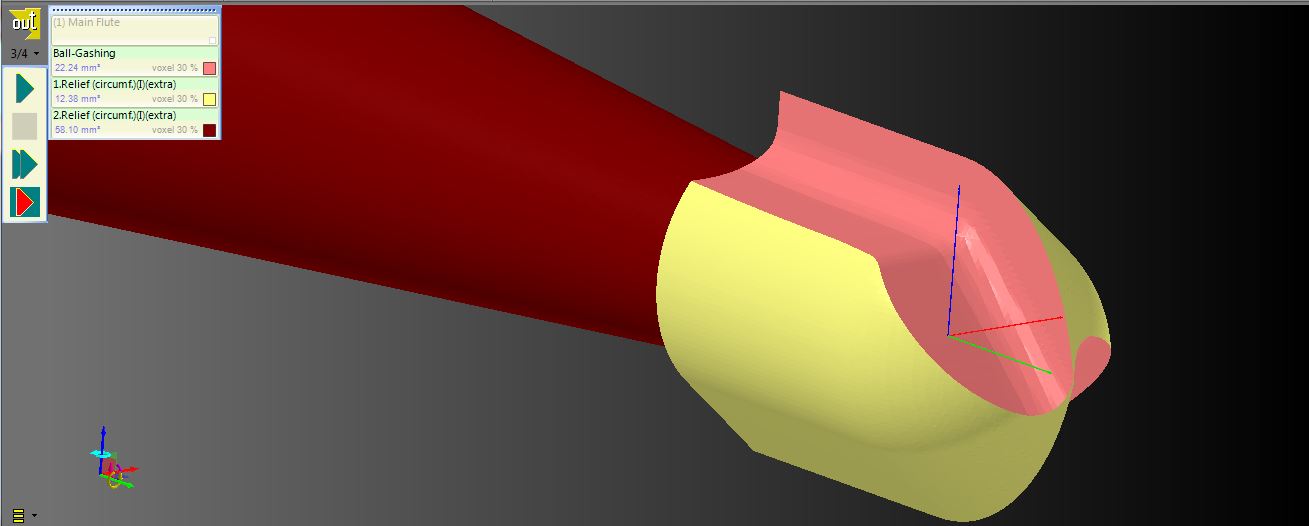

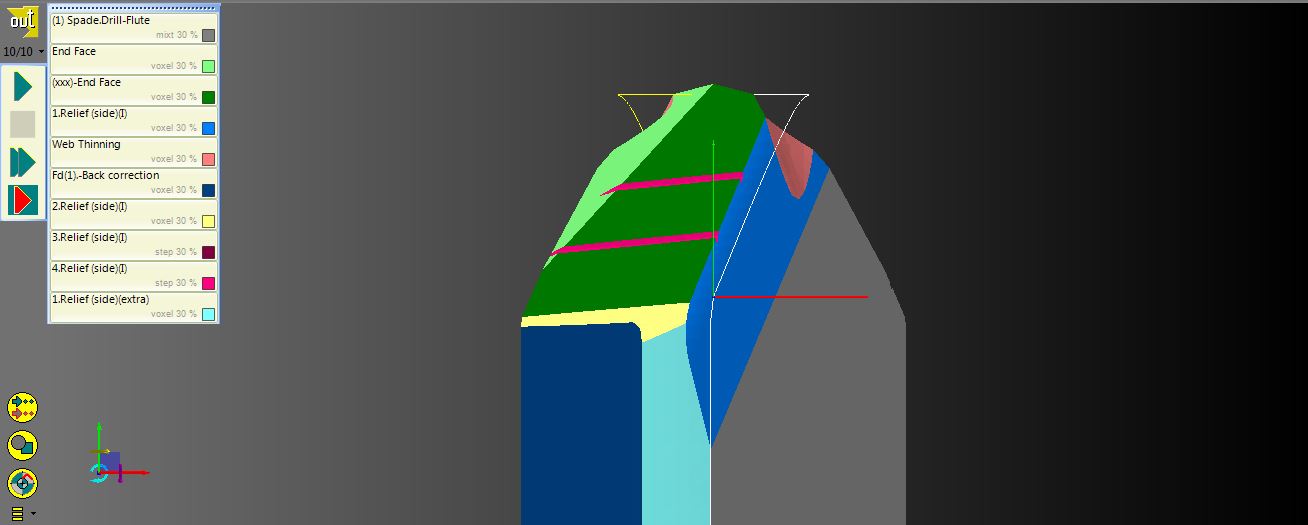

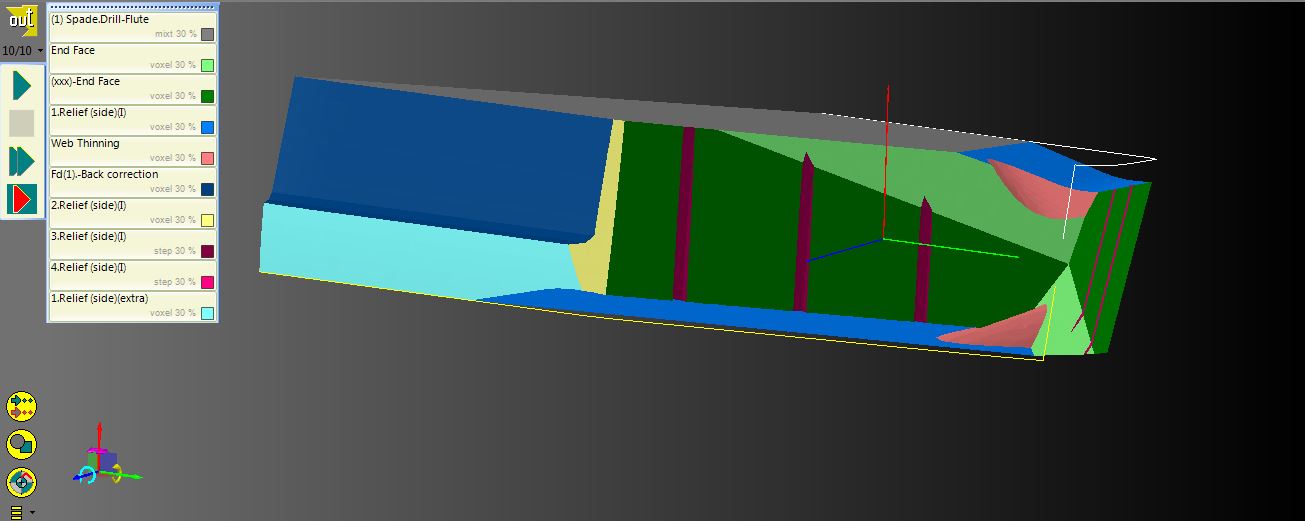

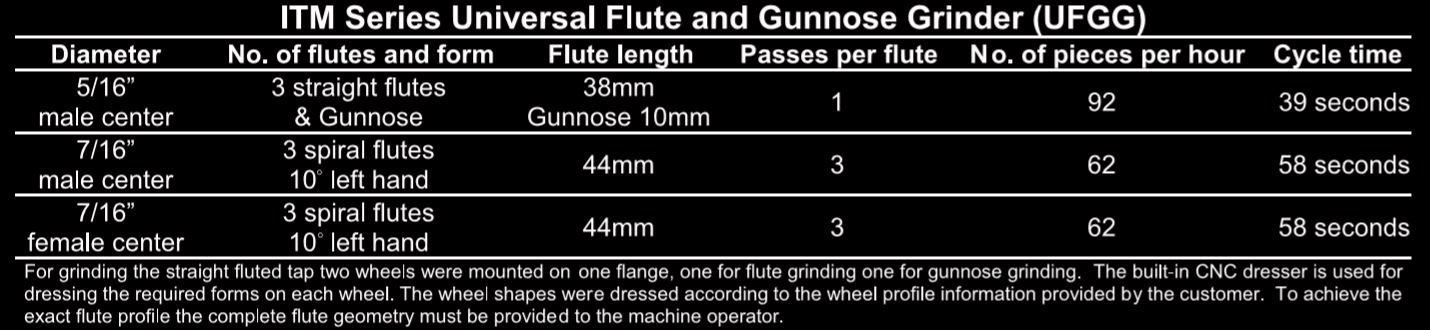

SAMPLE APPLICATIONS / GRINDING OPERATIONS

- Taps: Straight Flutes, Right & Left Hand Flutes, Spiral Point or Gunnose*

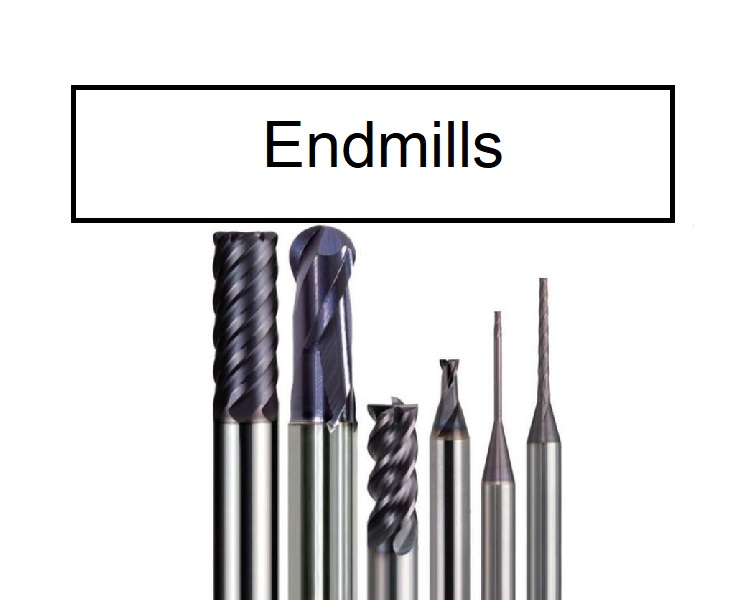

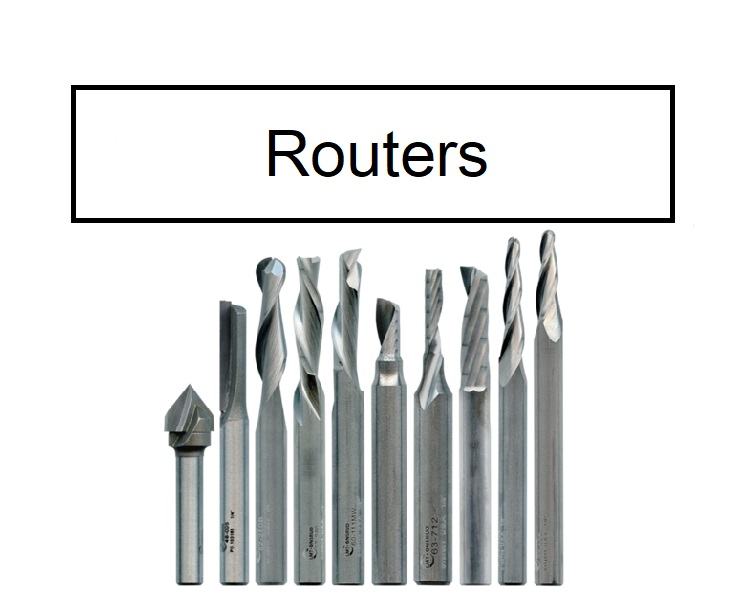

- Endmills – Carbide & HSS: Flutes, OD Relief*

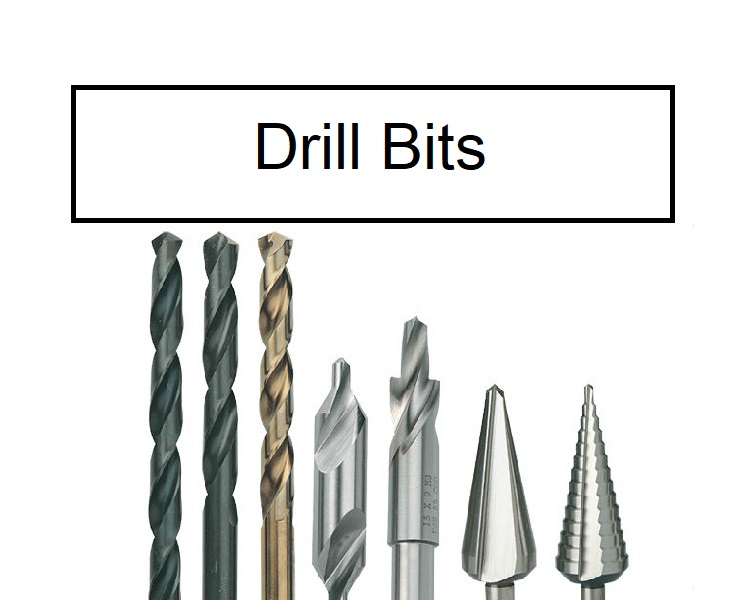

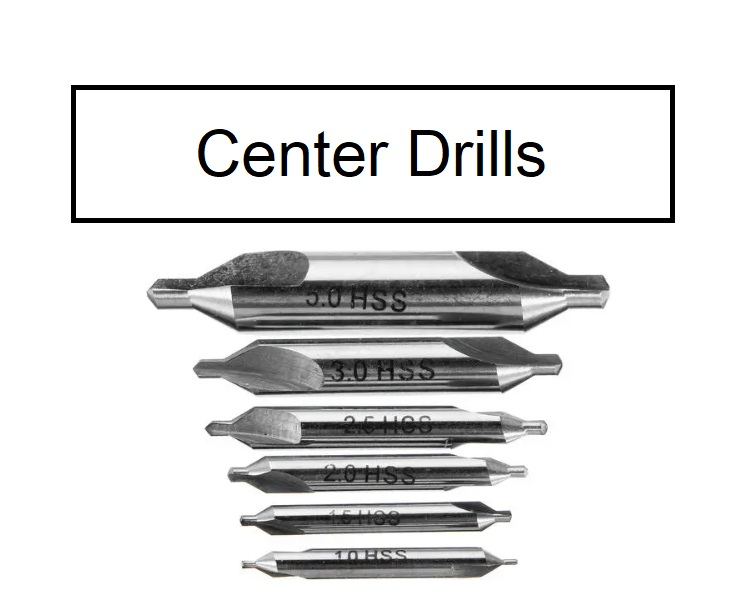

- Twistdrills (Industrial/ Aircraft/ S+D/ DIY/ Medical/ PCB) – Carbide, HSS & Stainless: Flutes, OD Relief*

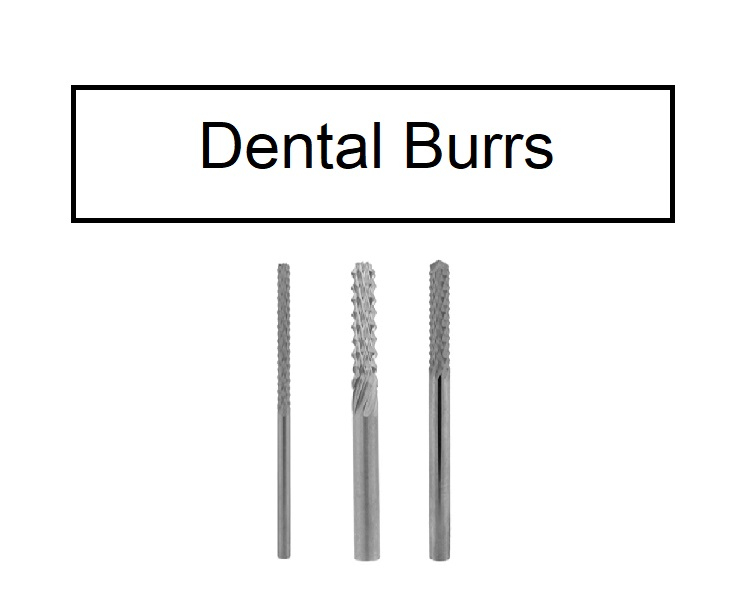

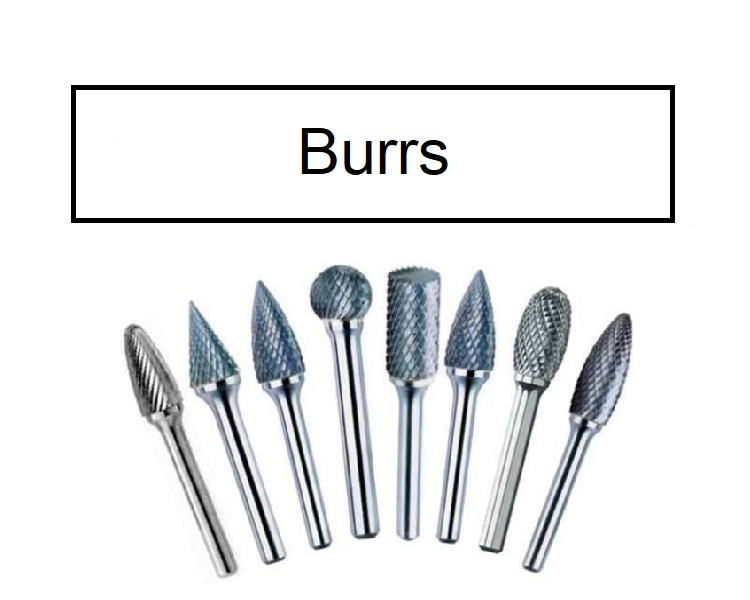

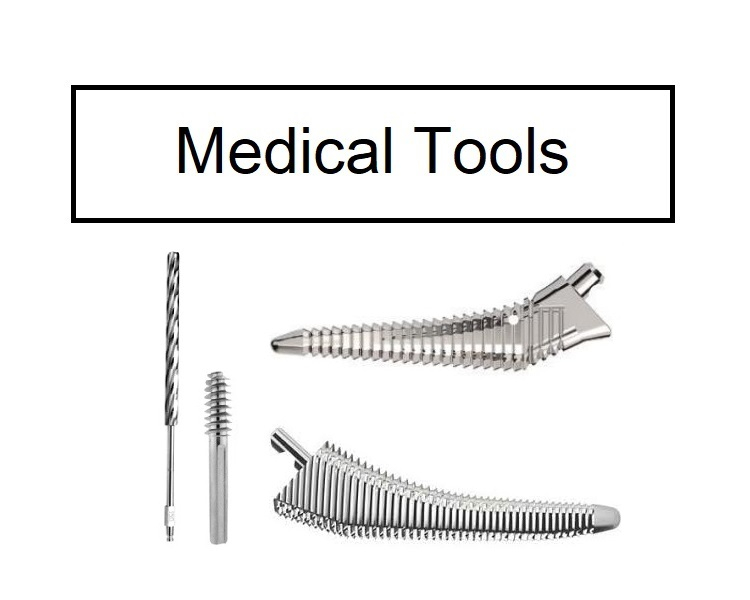

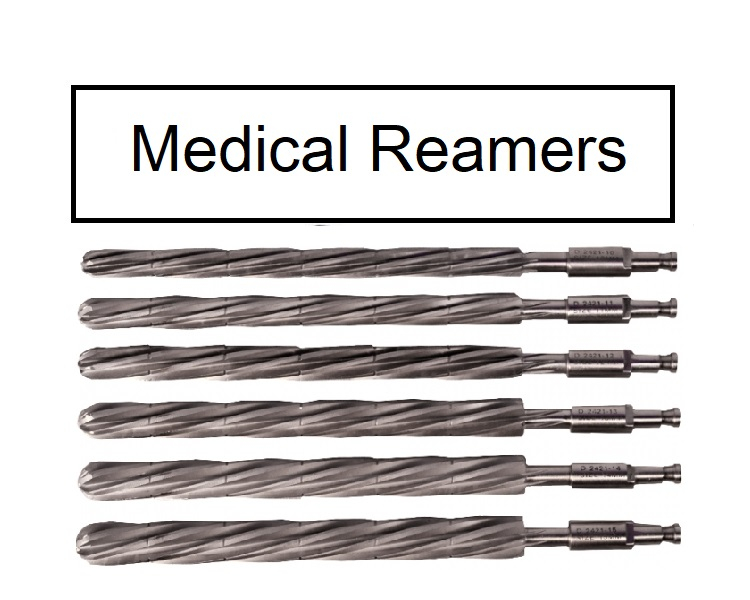

- Medical Tools – Stainless & Titanium: Fluting Drills, Reamers, Burs

- Reamers – Carbide & HSS: Flutes, OD Relief*

- Countersinks – Carbide & HSS: Flutes, Cone Relief, OD*

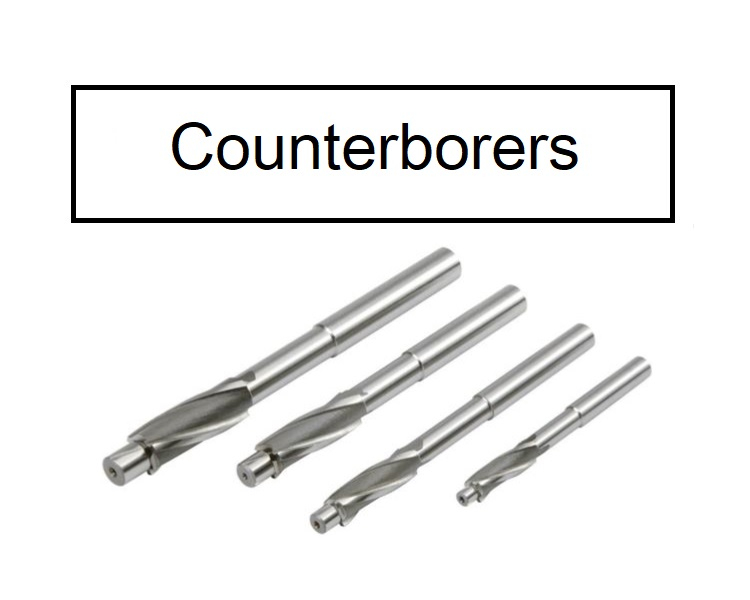

- Counterbores: Flutes, OD Relief, Pilot OD*

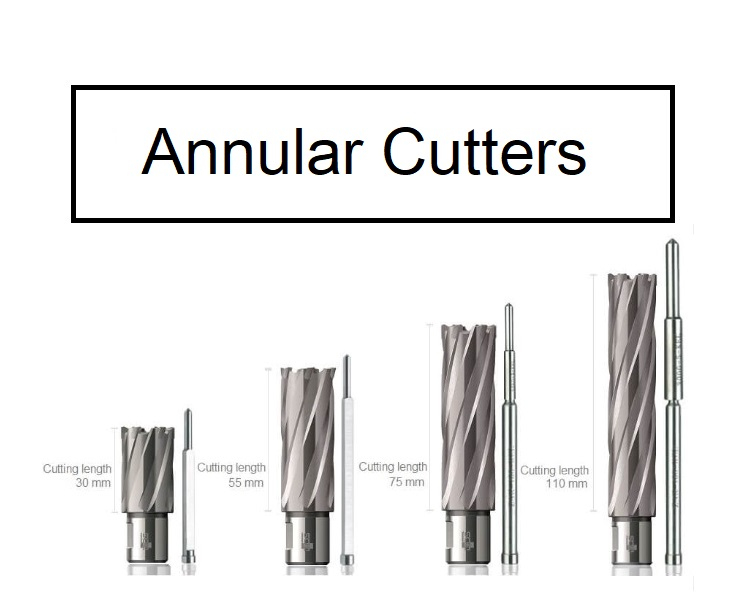

- Annular Hole Cutters: Flutes

- Cylindrical Burs – Carbide & HSS: Flutes, Chipbreakers*

- Cylindrical Routers – Carbide & HSS: Right & Left Hand Flutes*

- Form Relieved Cutters – Flutes, Relief*

* 2nd and 3rd Operation may have to be performed in separate set-ups.