MODEL: UODG – UNIVERSAL O.D. & CHAMFER GRINDING MACHINE

CHAMFER SERIES

ITM holds over 30 patented machine designs

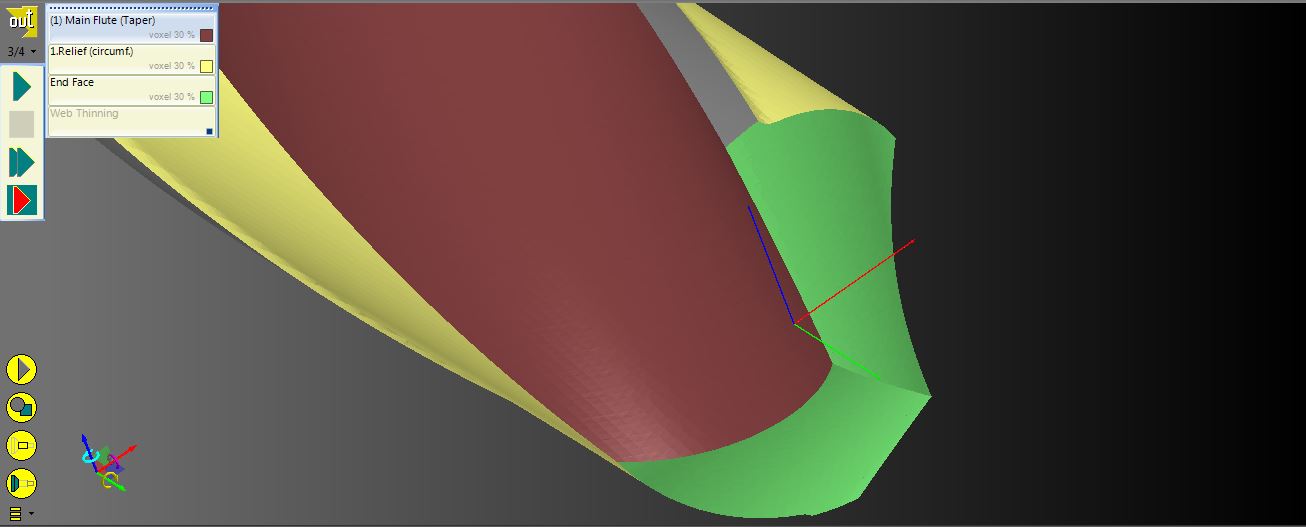

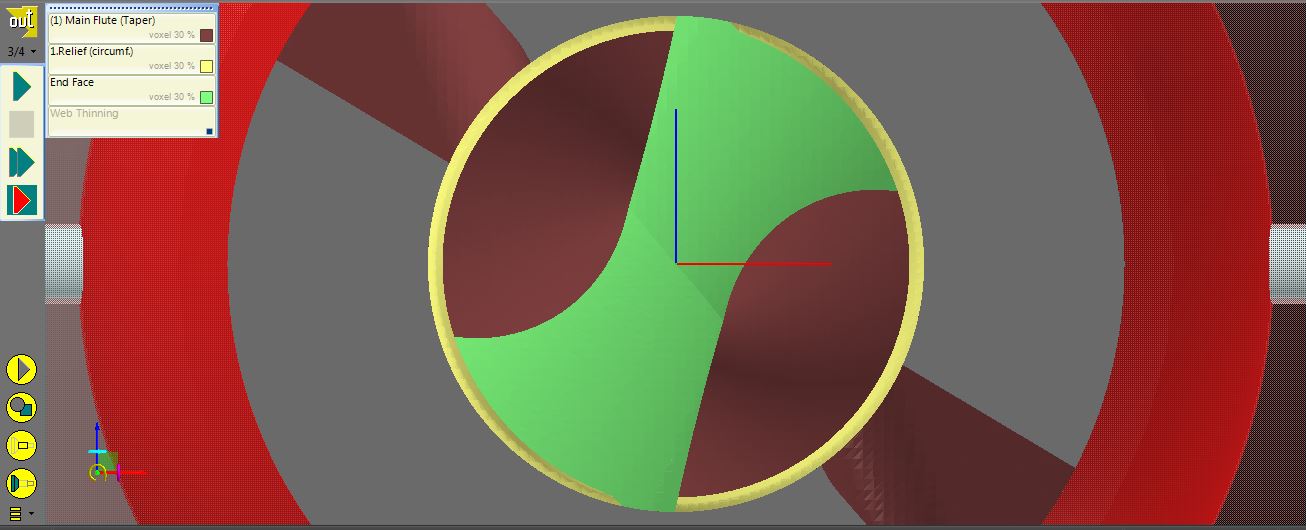

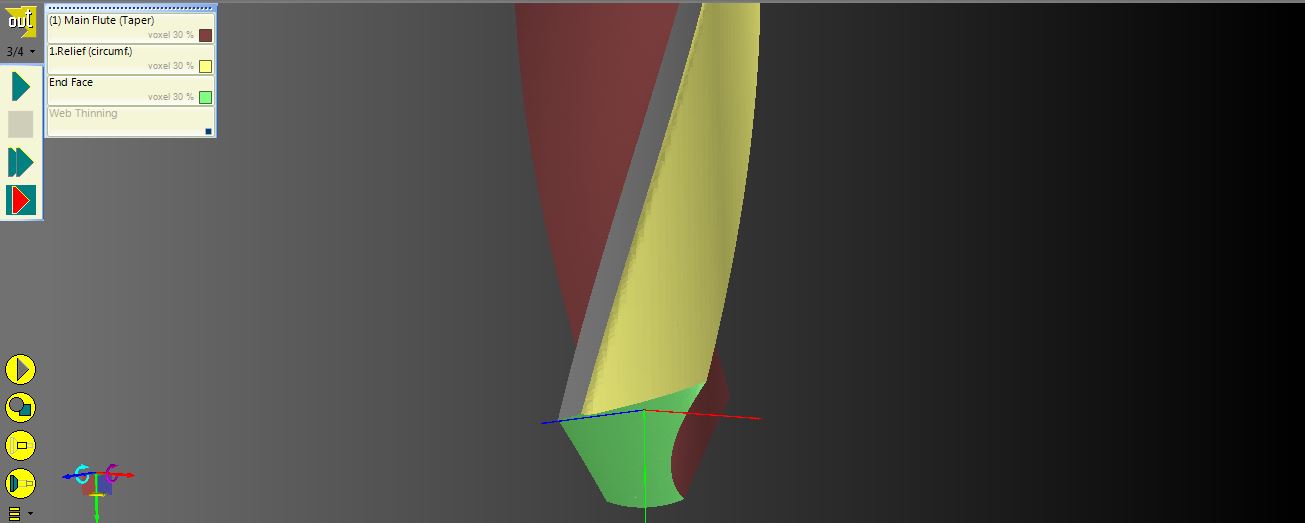

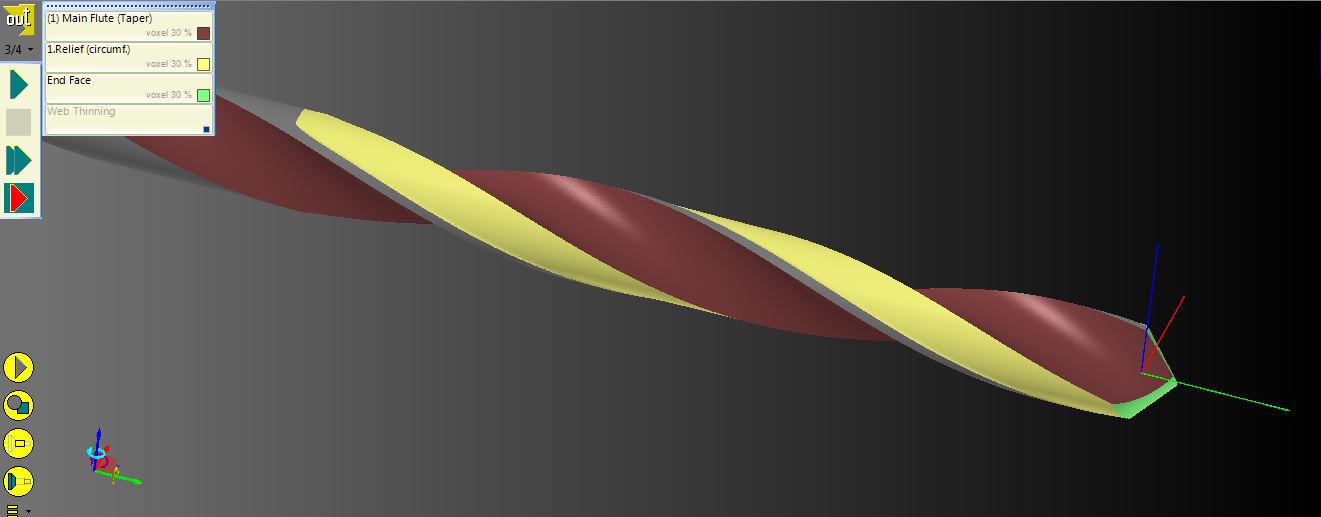

TARGETED SIMPLE SOLUTION FOR GRINDING HIGH HELIX TAPS WITH EXTREMELY LONG CHAMFERS

FAST AND EFFICIENT CHAMFER GRINDING

The consistent production of precision chamfers and countersinks require efficient, high-performance grinding machines. The ITM UODG is the solution for quick set-up of all your chamfering jobs. The ITM UODG is a universal OD grinding machine for chamfering straight and helical right-hand and left-hand taps, taps with front and main chamfer with or without relief, taps with OD relief, taps with chamfered back angle, and taps with extra-long chamfers (using multiple plunge option). The workhead is mounted on a heavy precision slide which is moved by a variable speed hydraulic cylinder for loading and unloading tools. It can be equipped with a center or a square driver, or with an ultra-precision collet for the grinding of the tool between the centers.

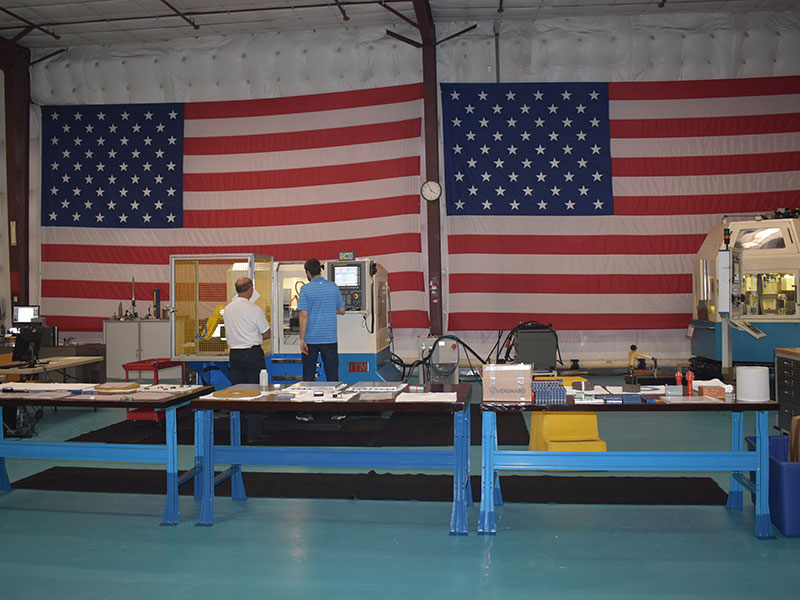

Preparing for new customer visit

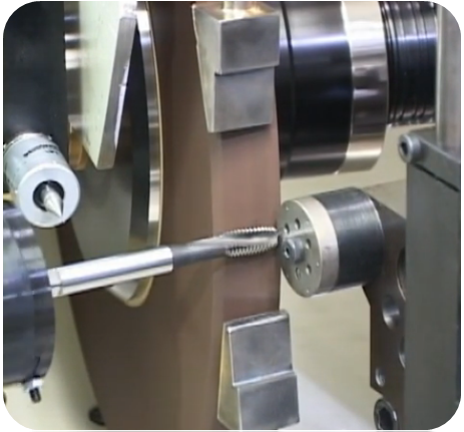

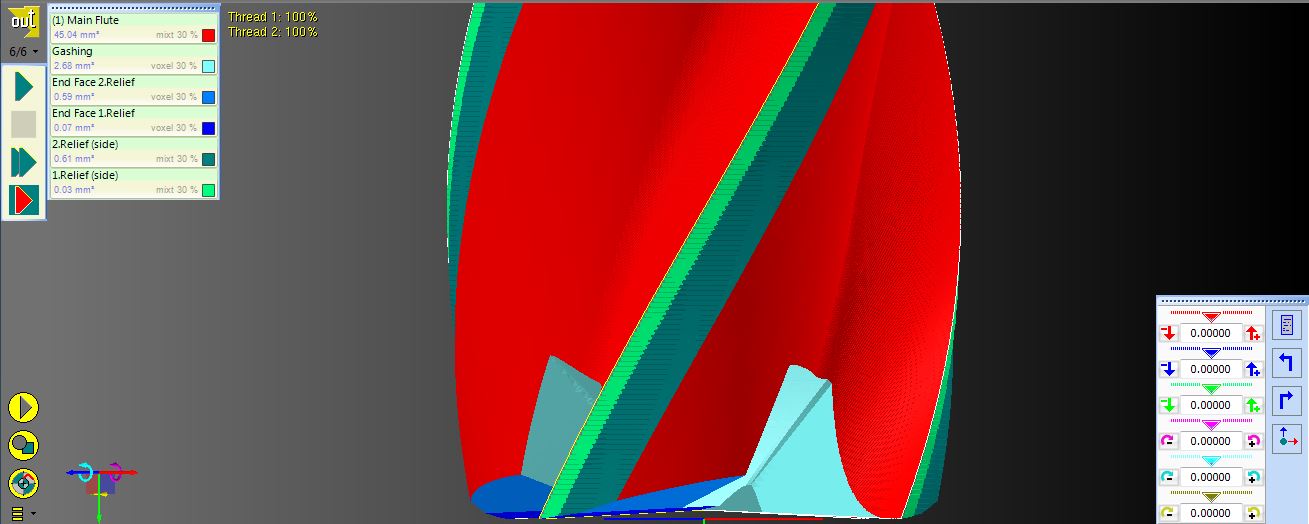

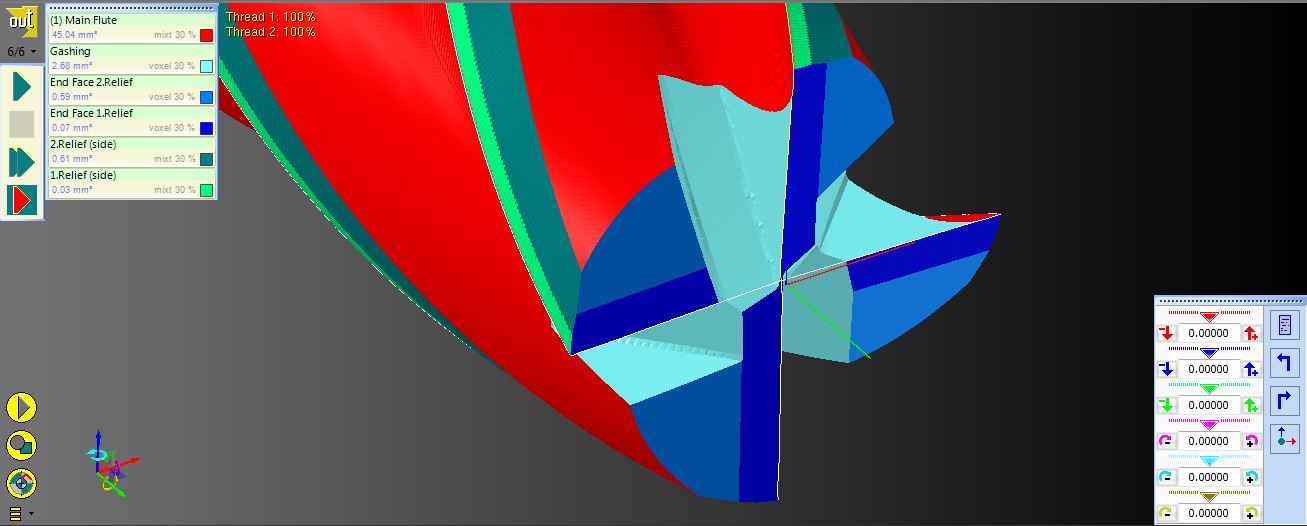

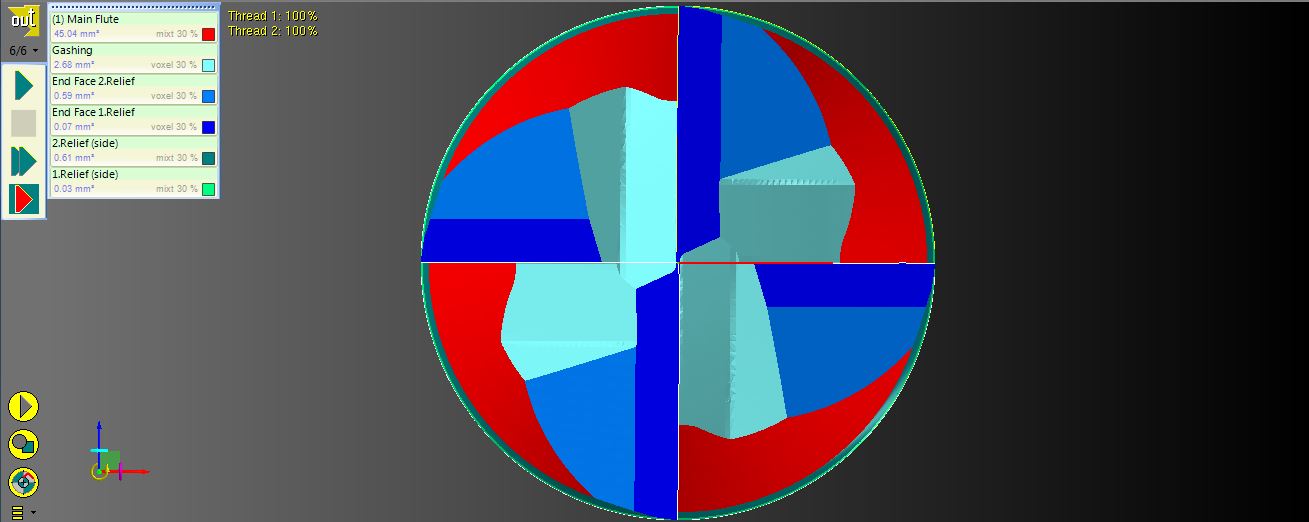

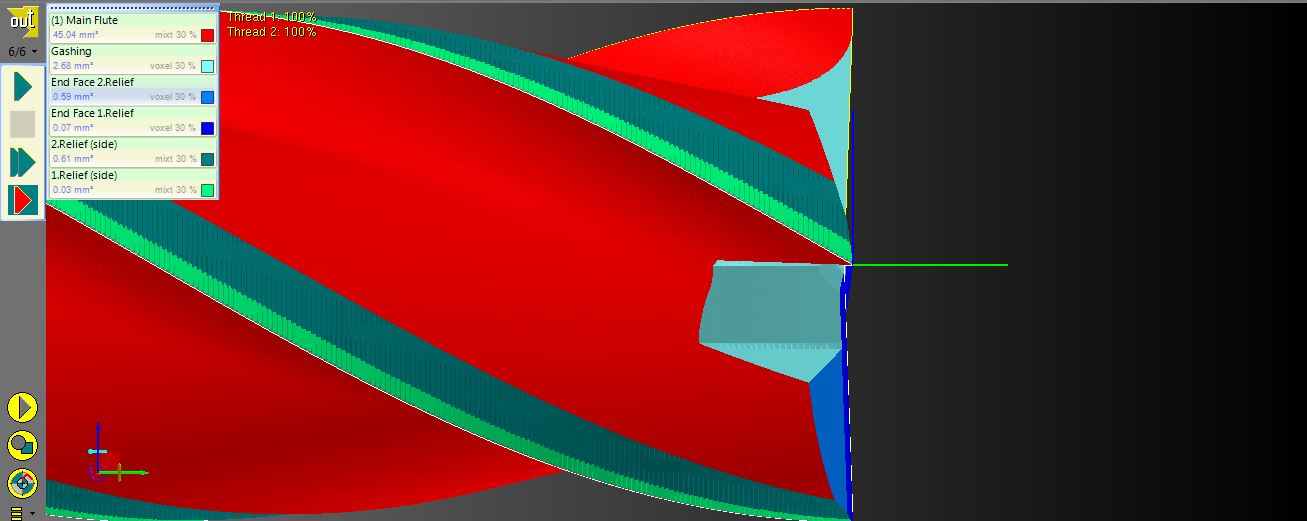

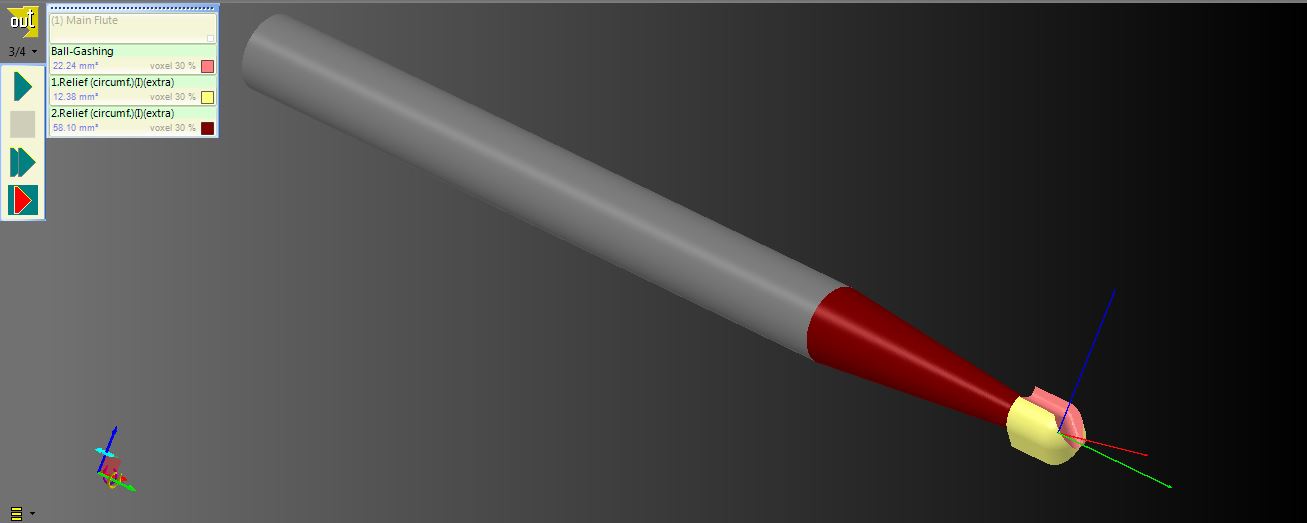

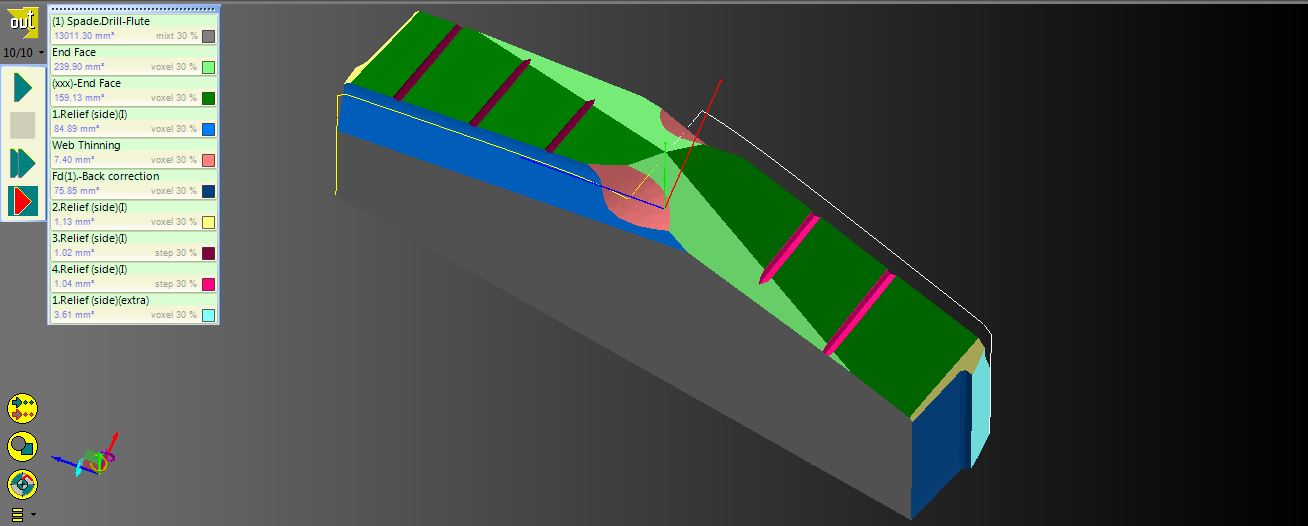

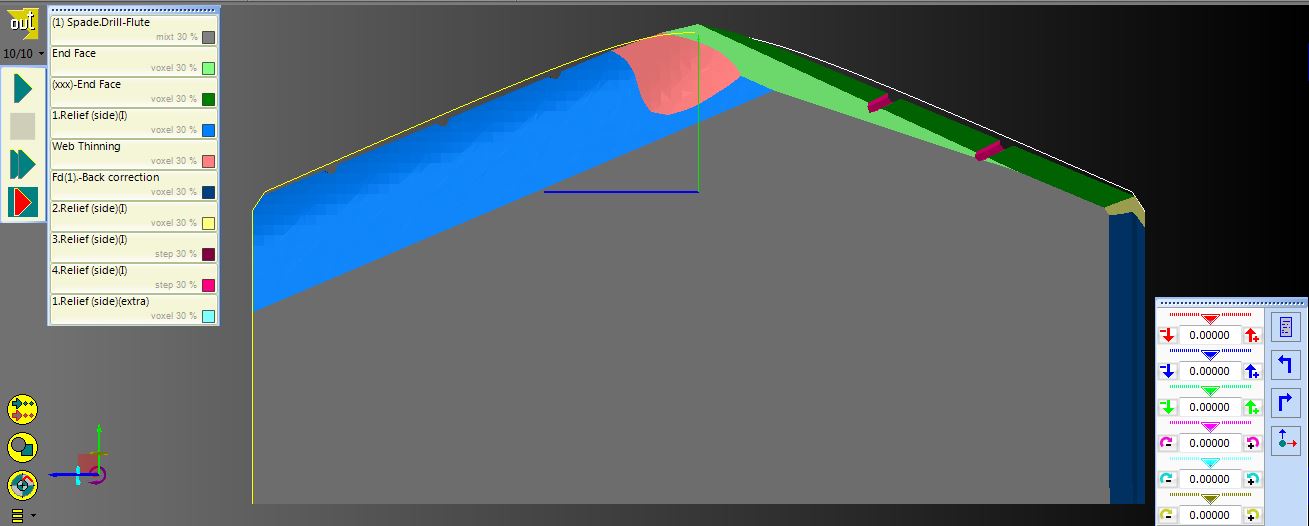

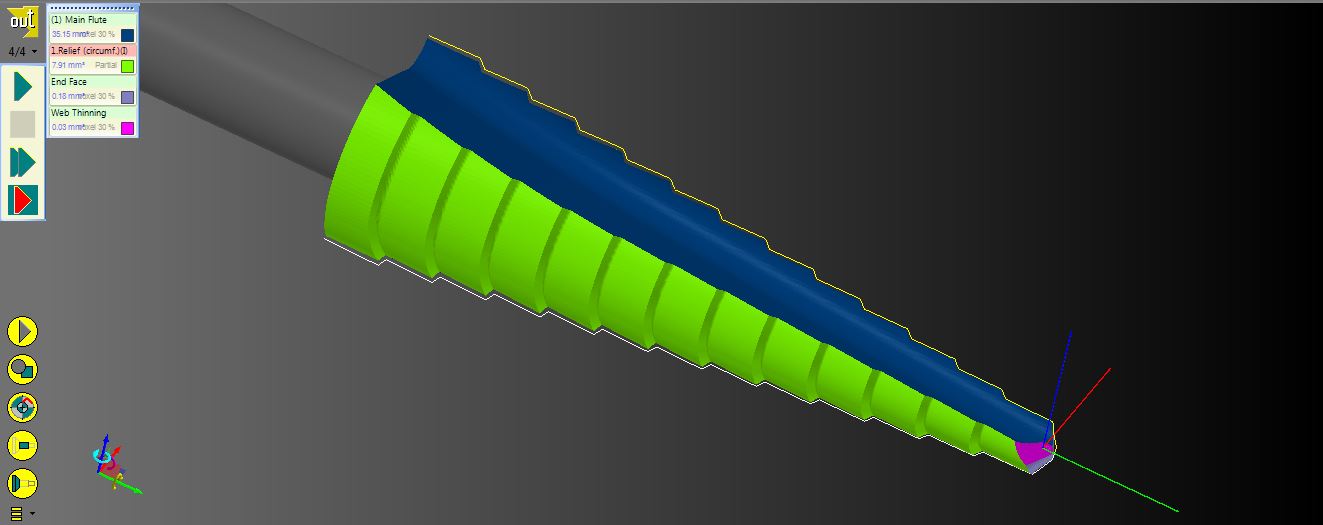

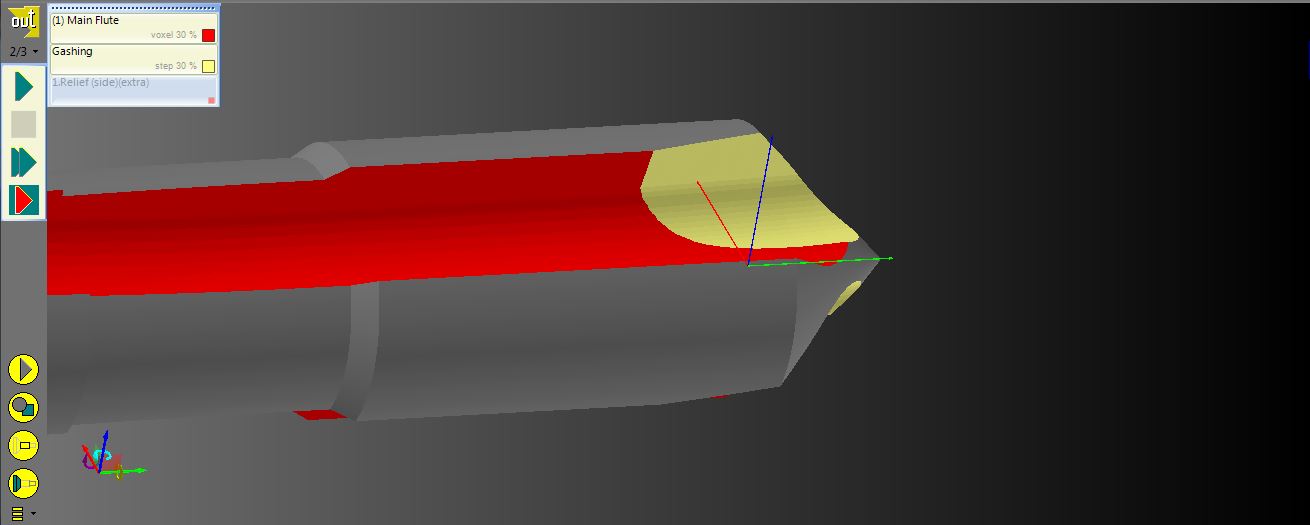

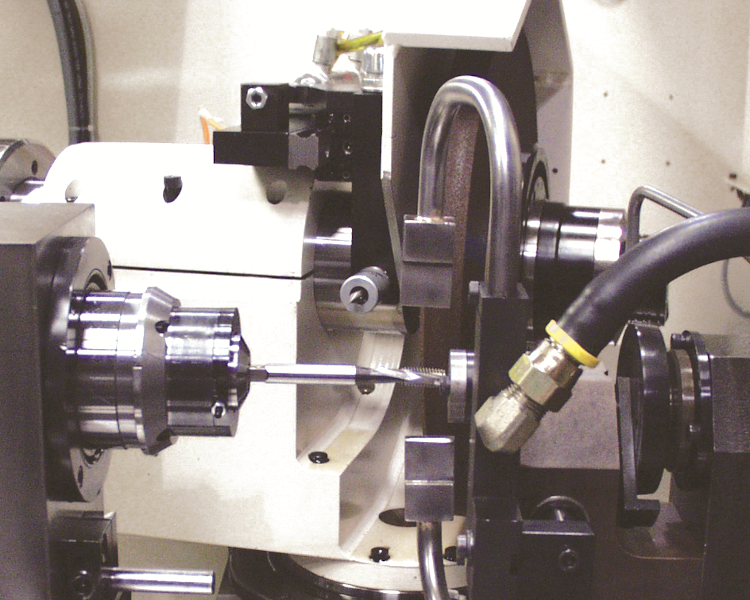

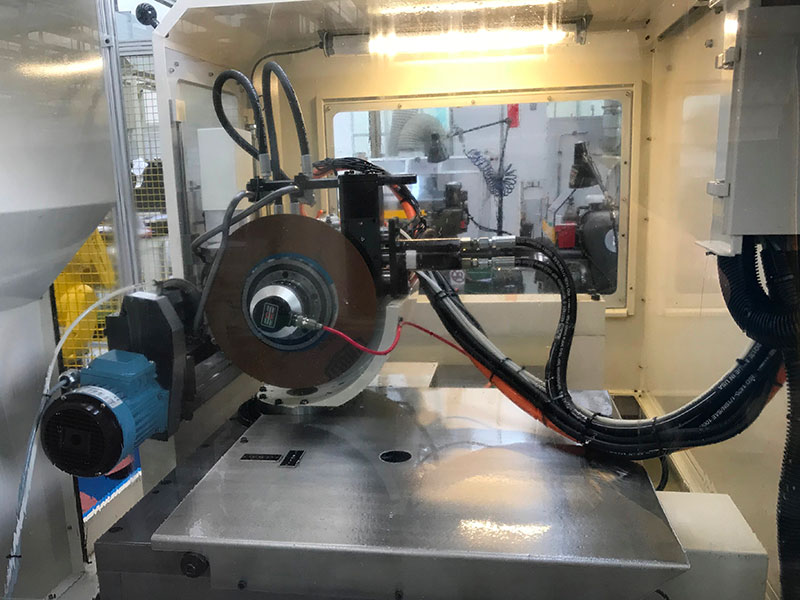

Inside of a UODG from the side window

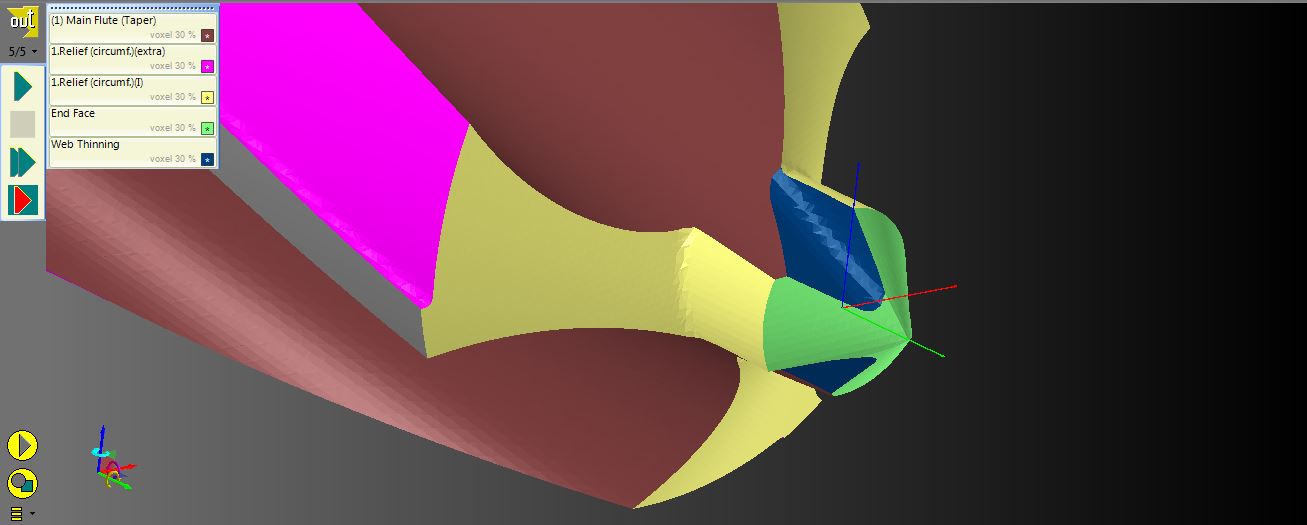

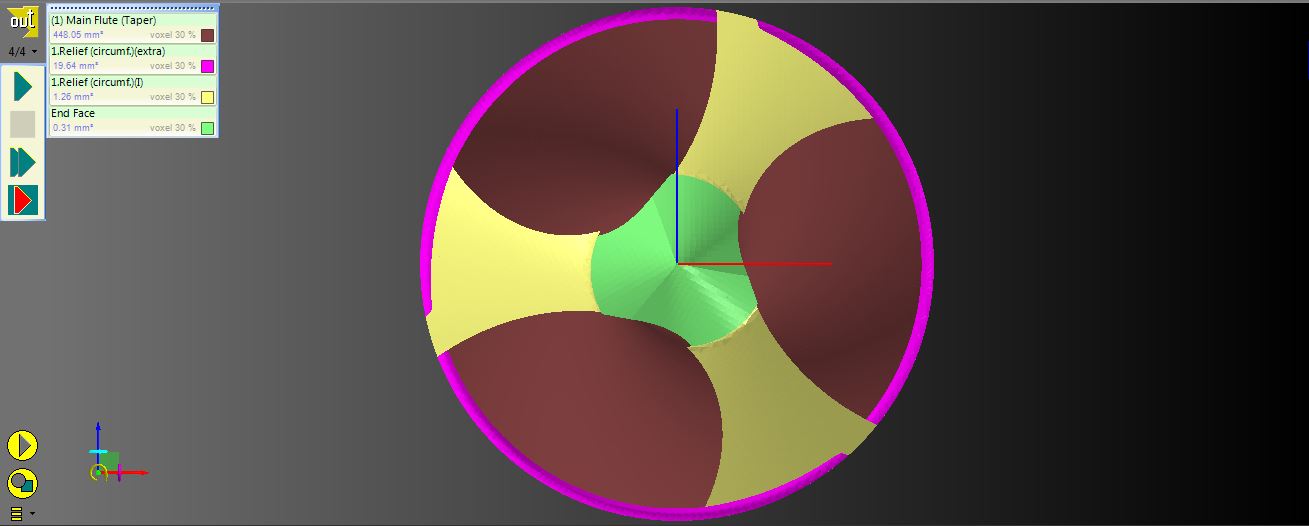

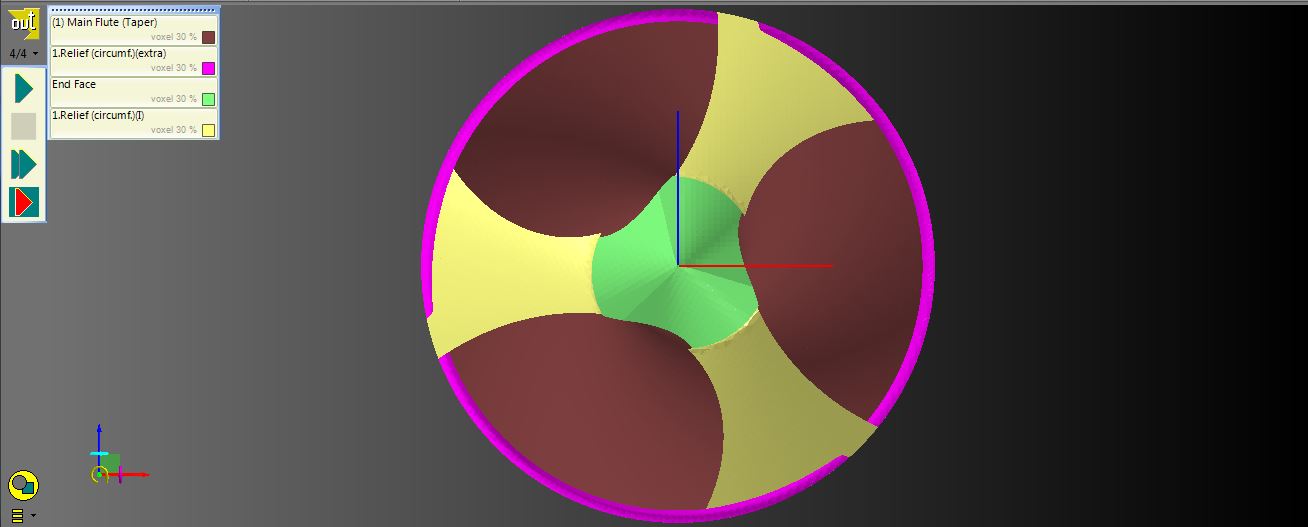

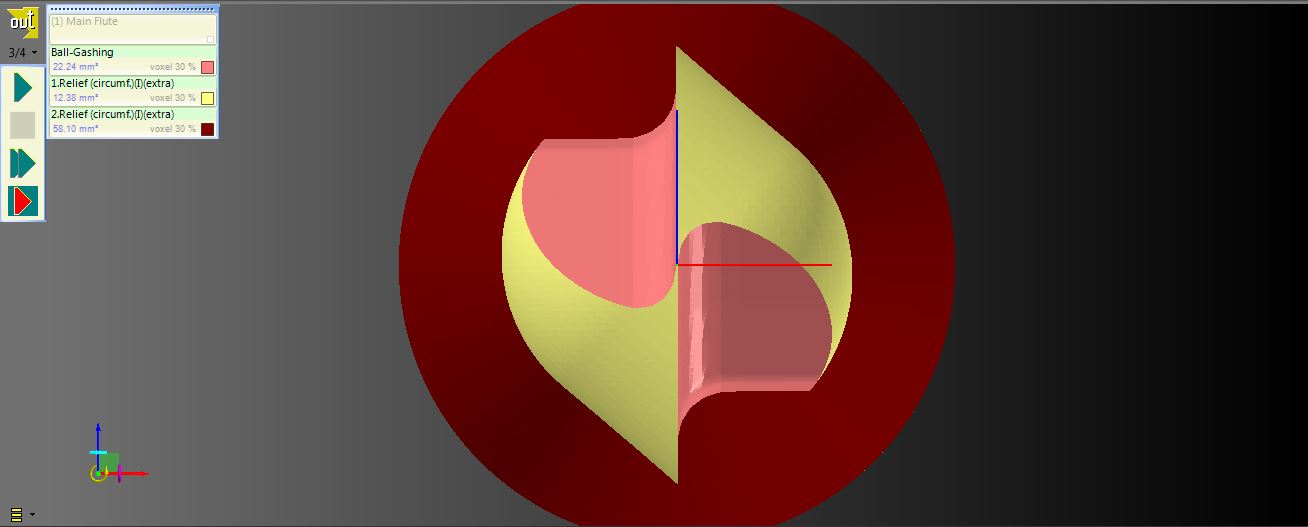

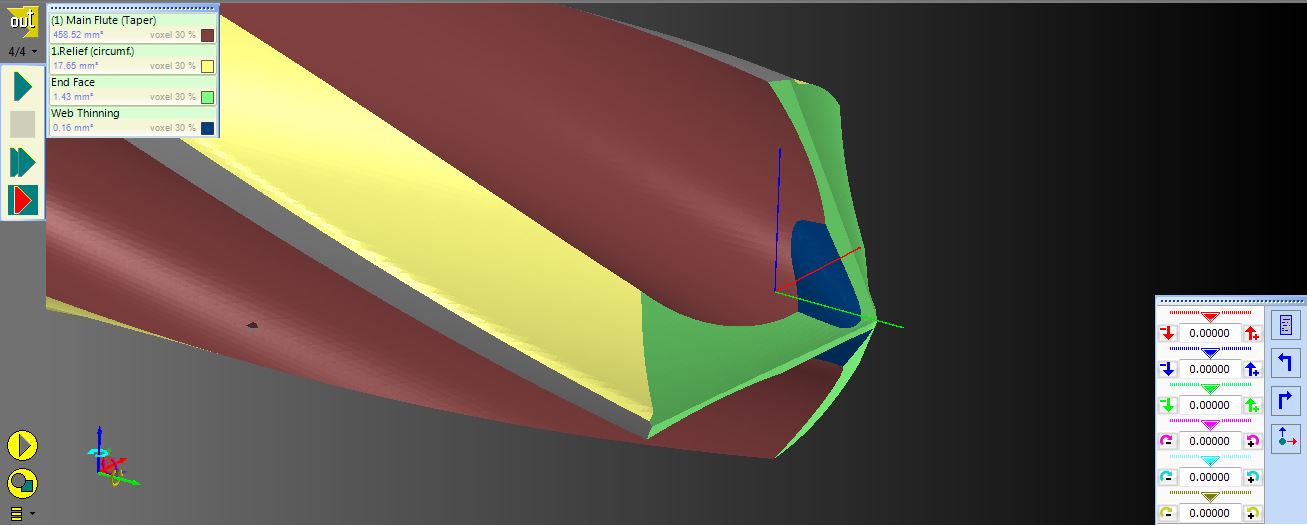

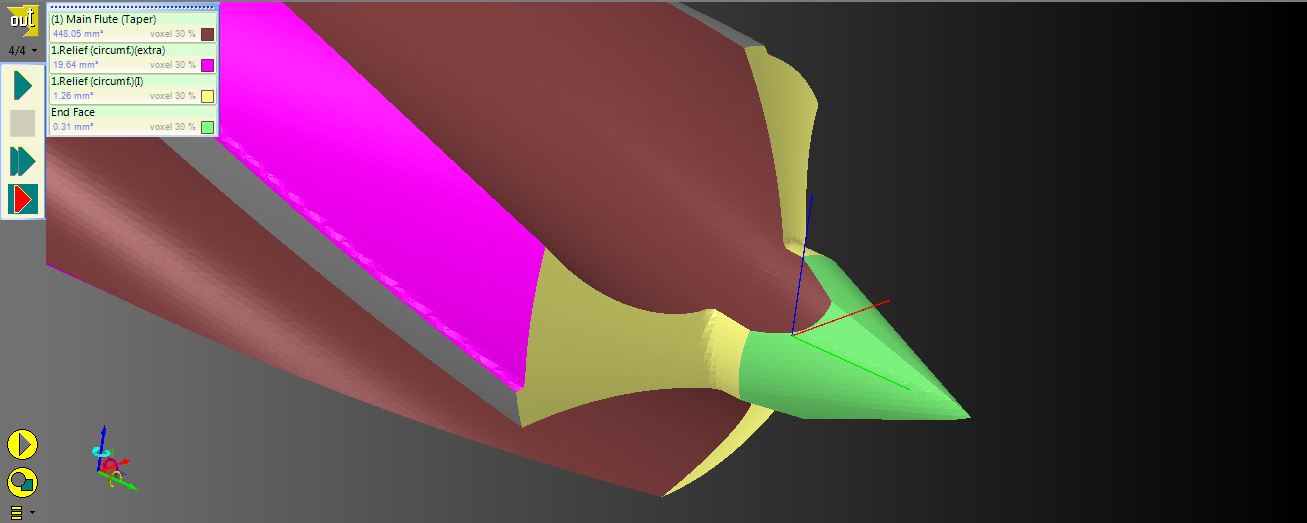

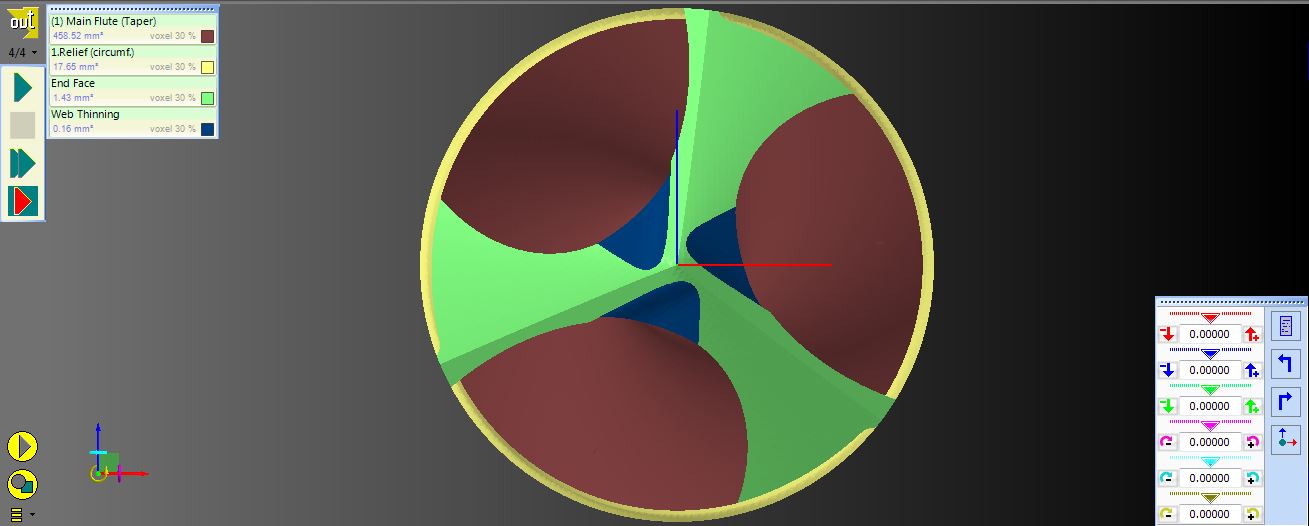

HOW IT WORKS

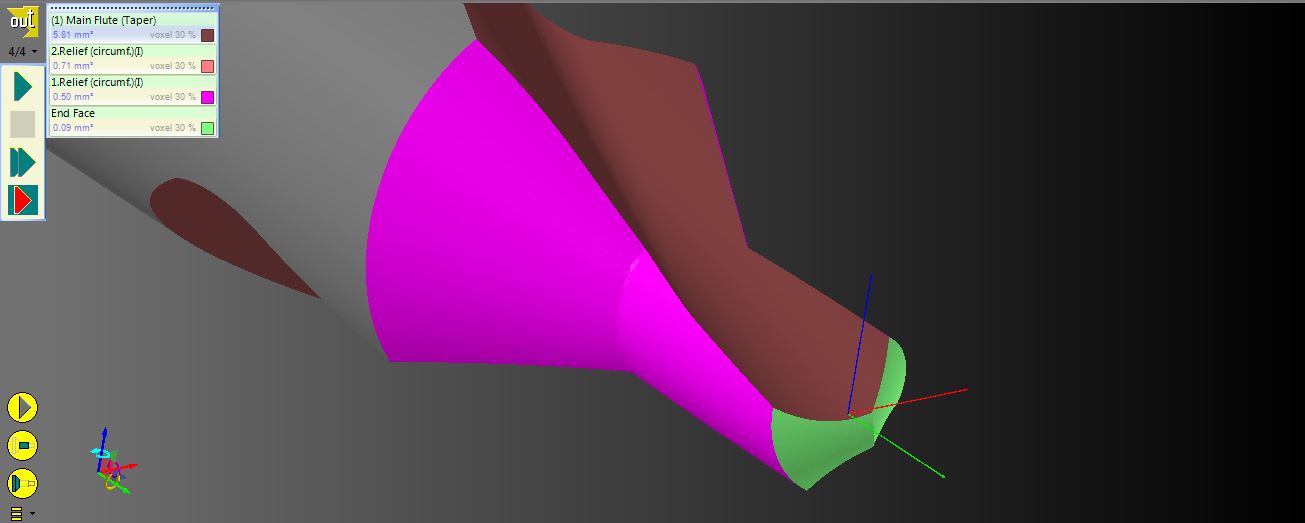

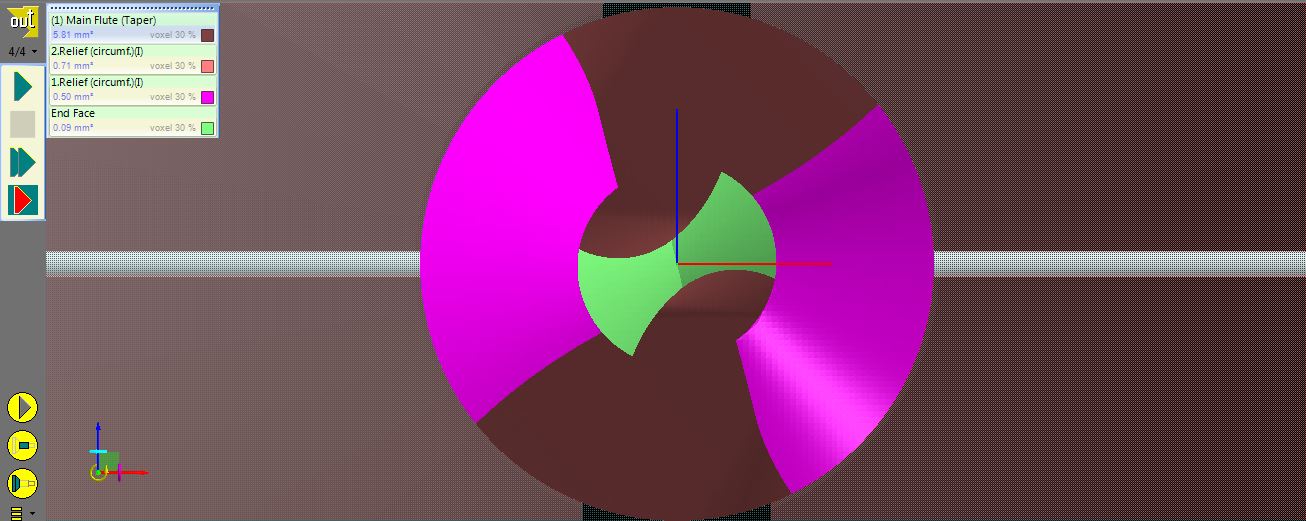

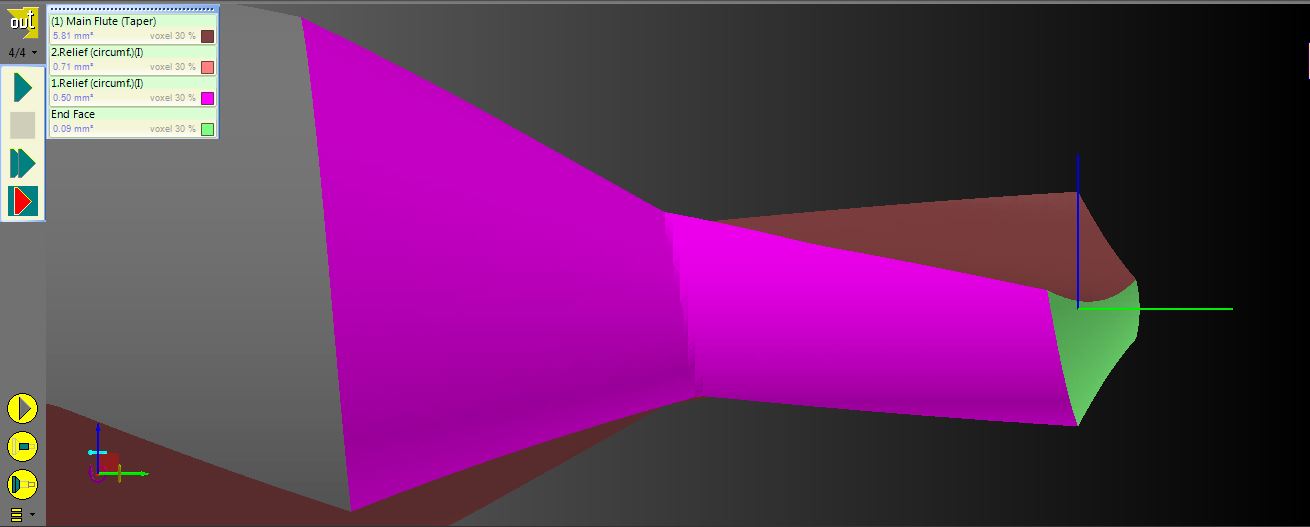

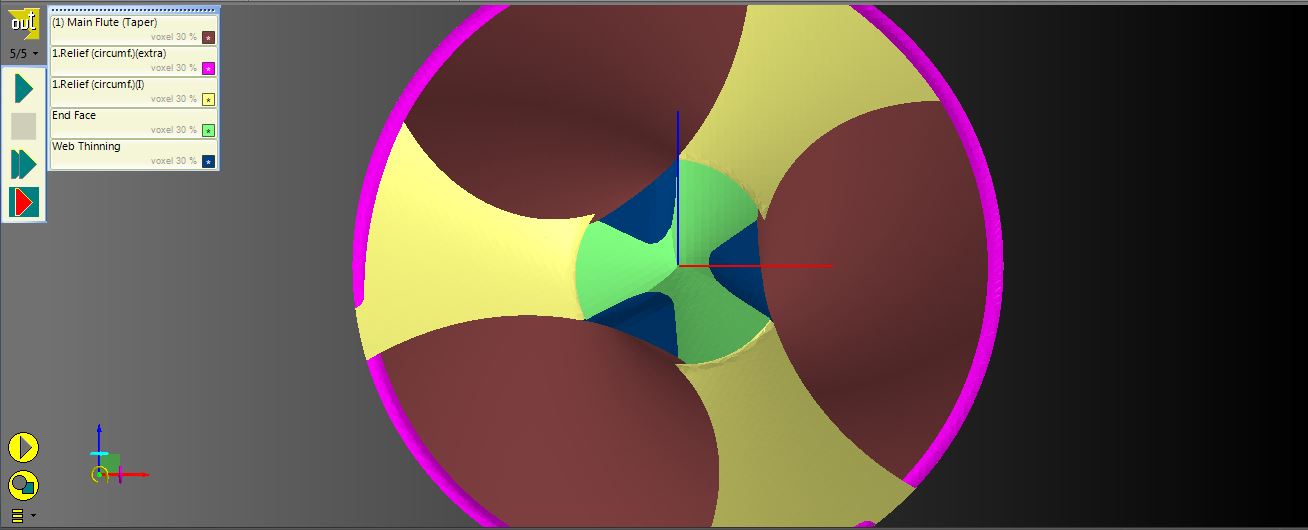

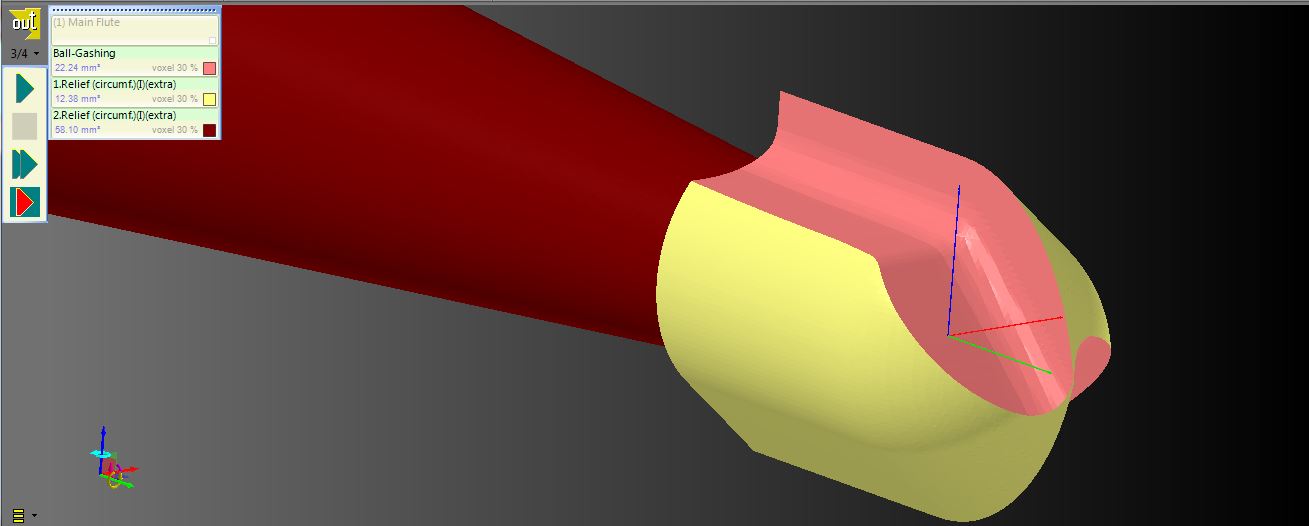

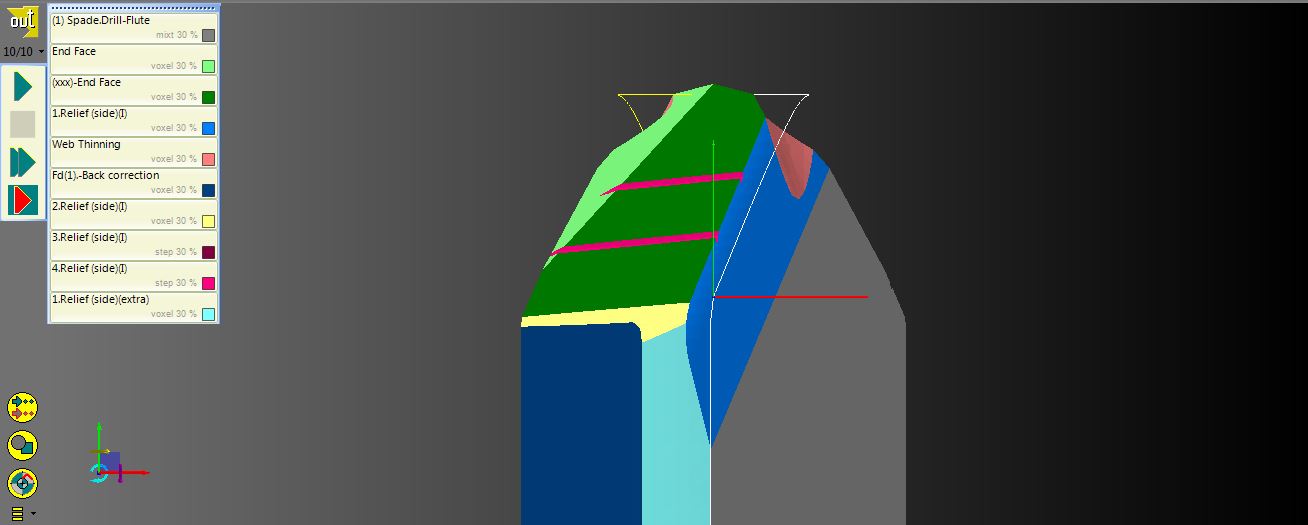

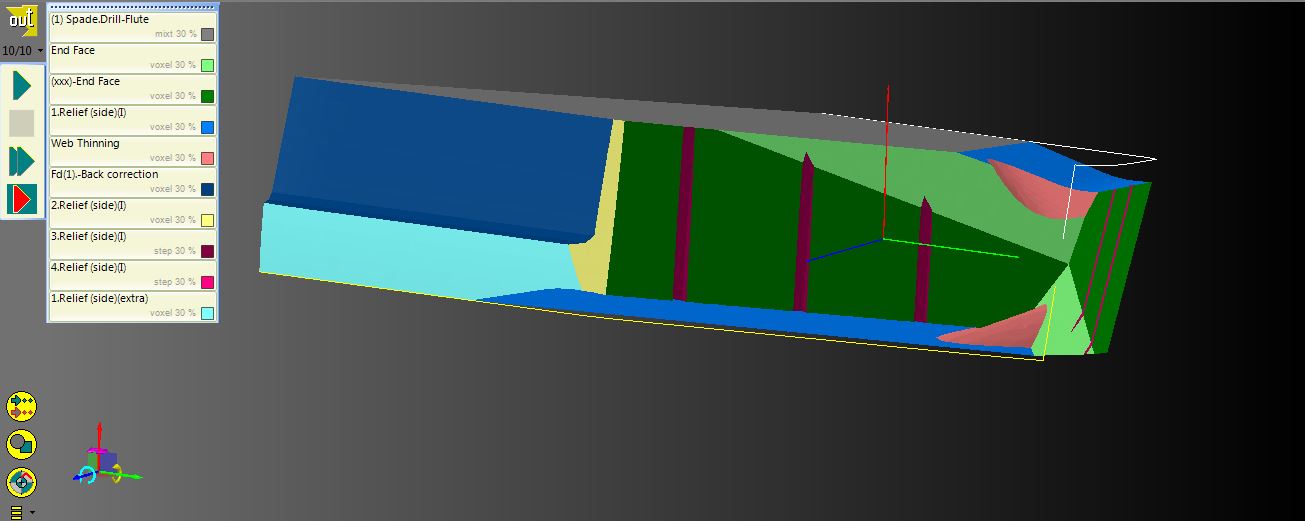

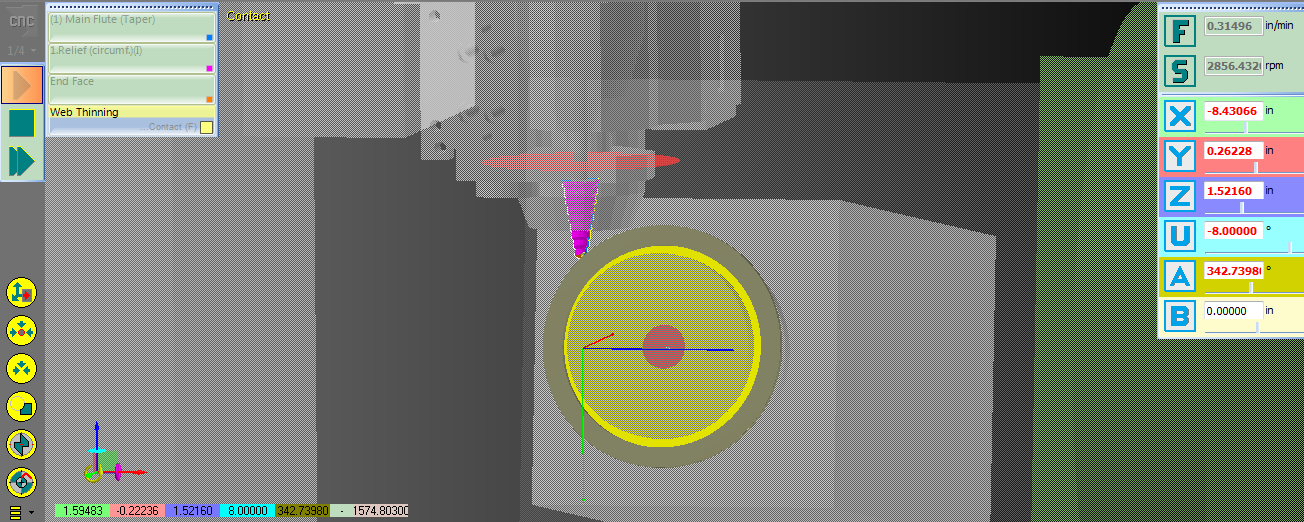

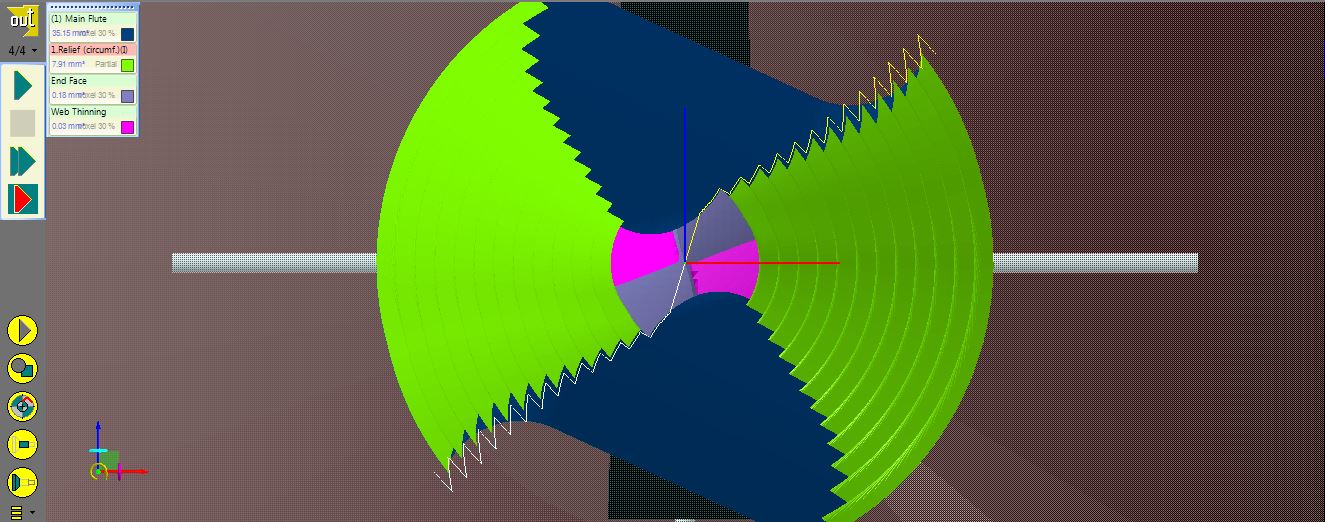

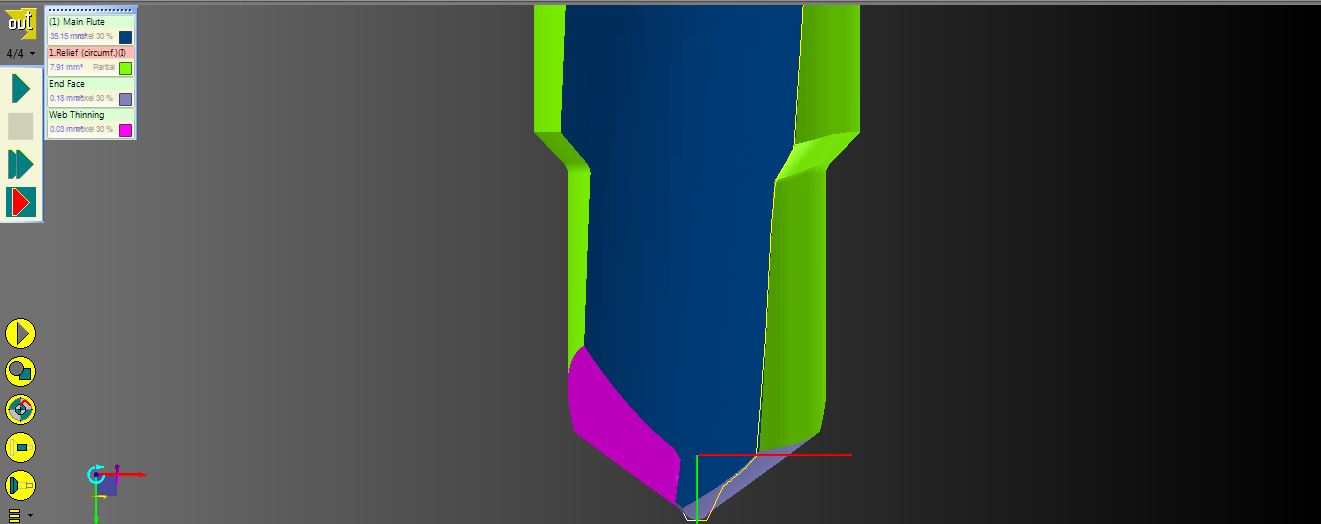

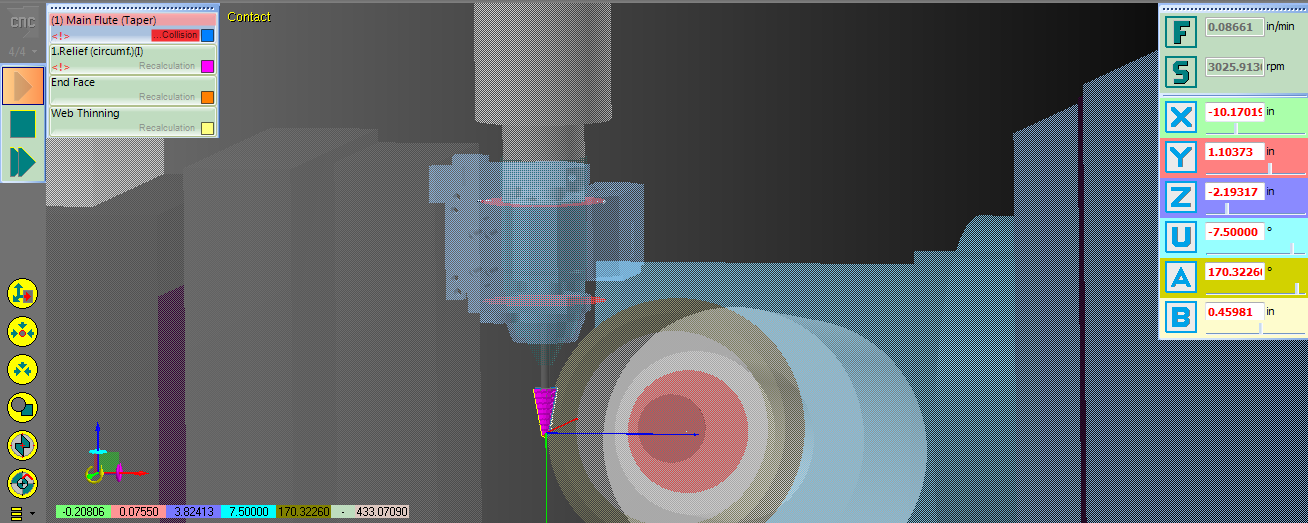

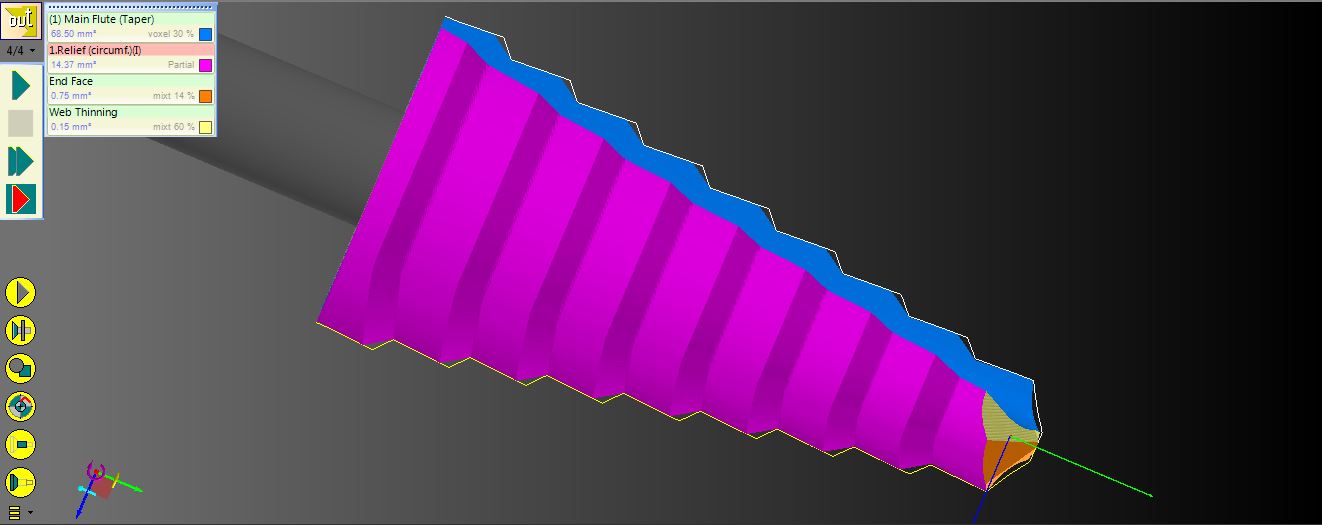

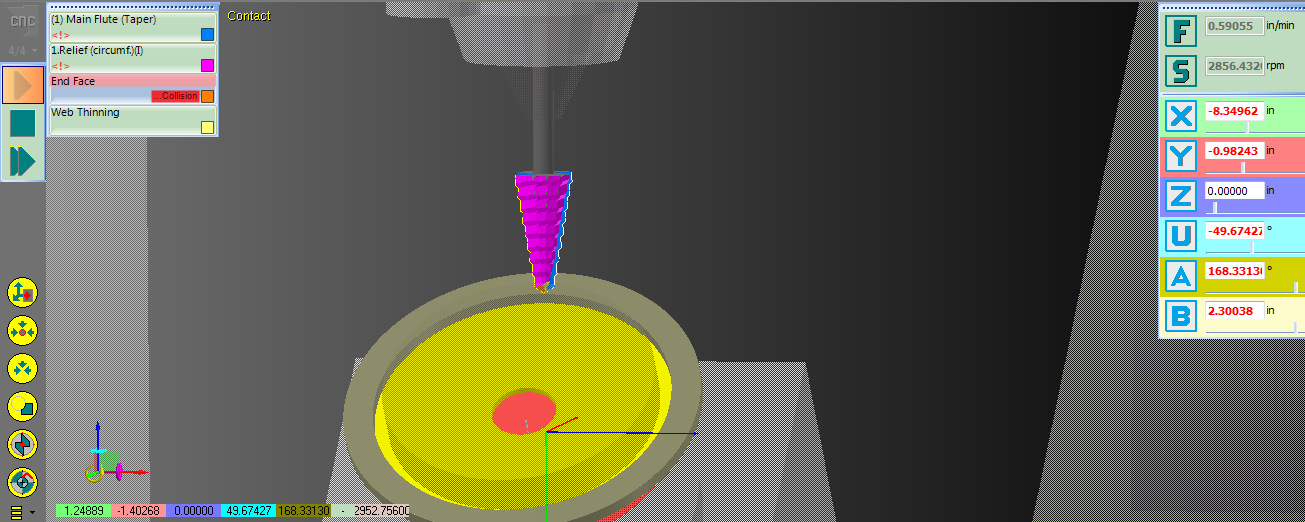

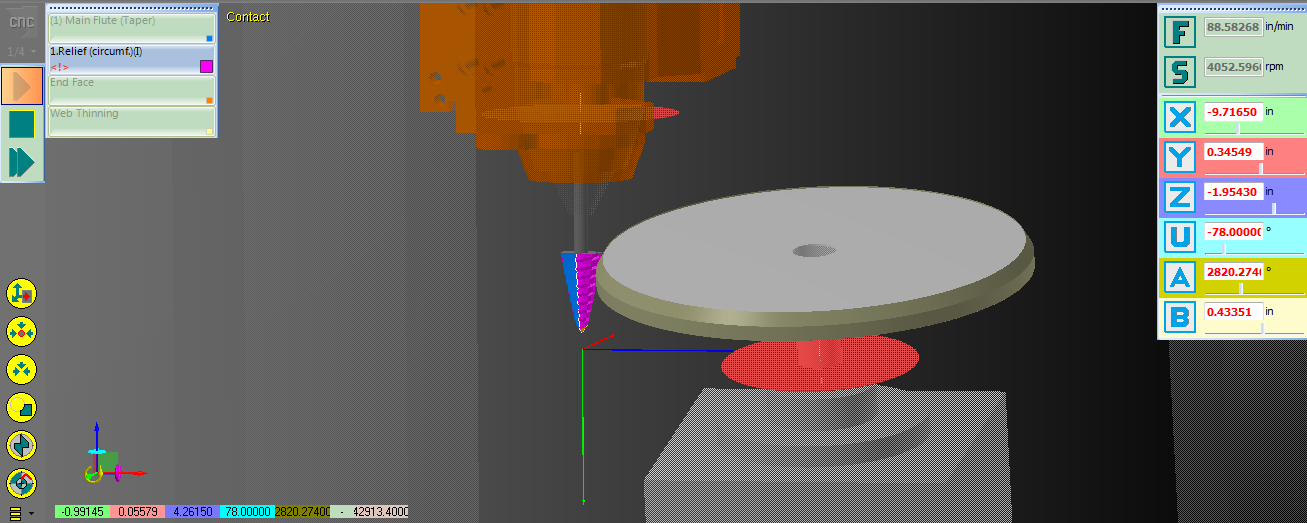

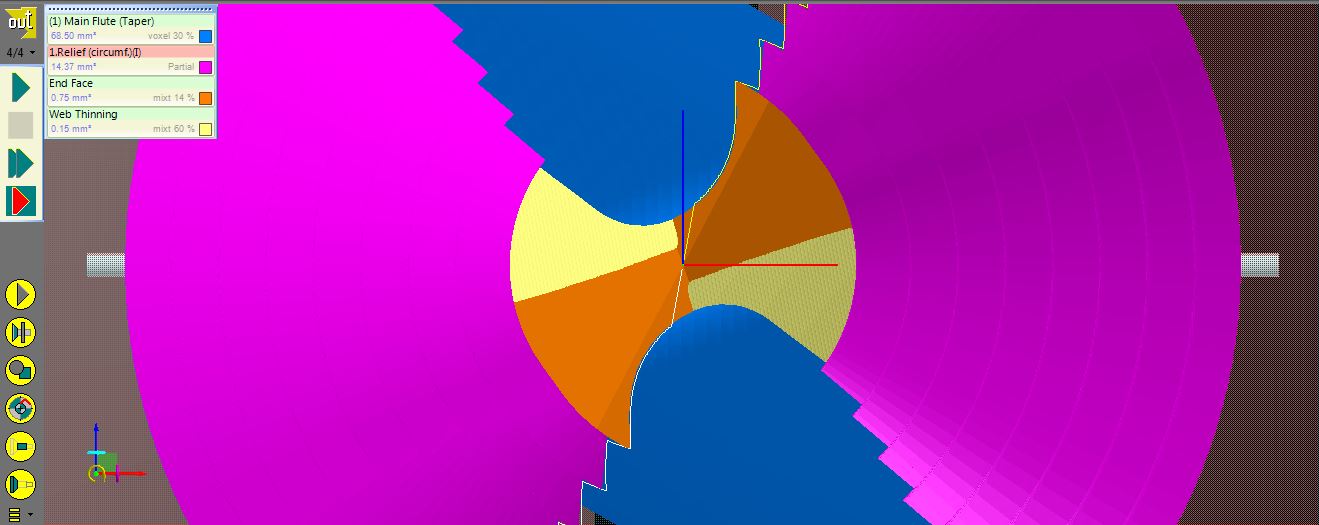

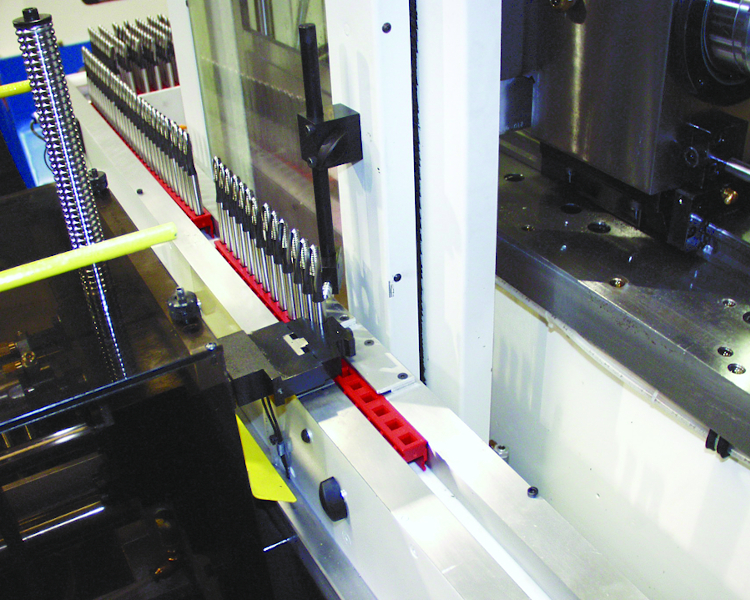

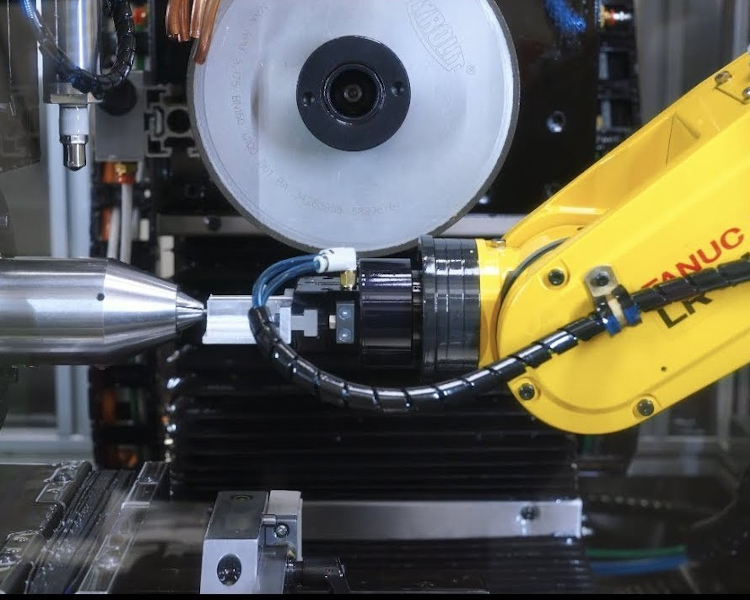

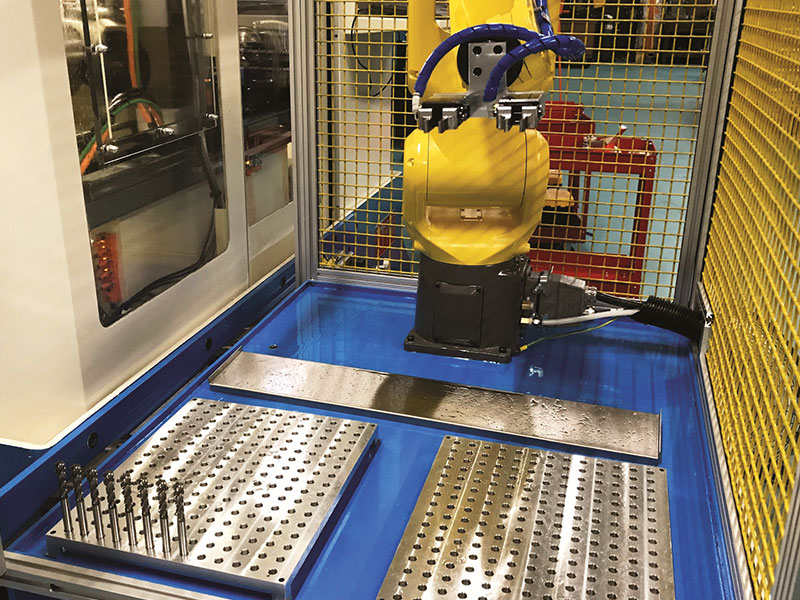

During chamfer grinding, the tool is supported between centers on a sturdy tailstock mounted in a fixed position on the machine base. This set-up allows for quick and easy changeovers to different tools because the tip of the tool always determines the location. The machine is either equipped with an automatic cassette loading system or a Fanuc™ robot work cell that uses standard cassettes or pallets for extended production runs. With multiple simultaneous controlled CNC axes, setup time is short, making the machine economical for both large and small production runs. Since the distance from the face of the wheel flange to the point of the tail stock center is known, the operator only needs to enter basic parameters such as tool length, OD, chamfer angle, chamfer length, and the relief angle. A Renishaw™ probe can be installed to locate the flutes in automatic grinding process.

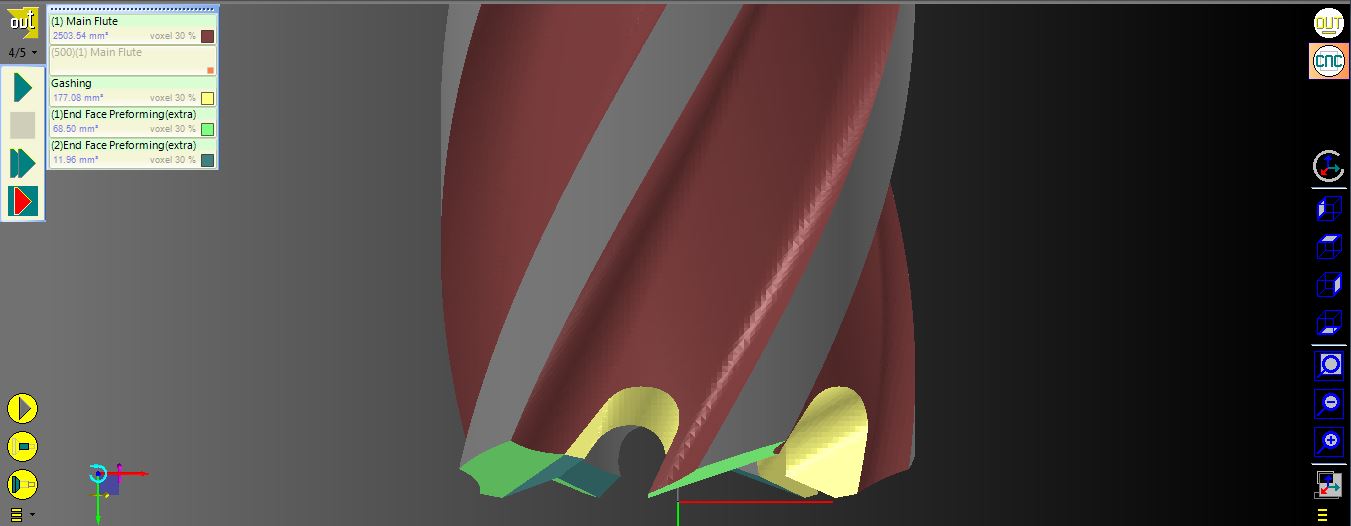

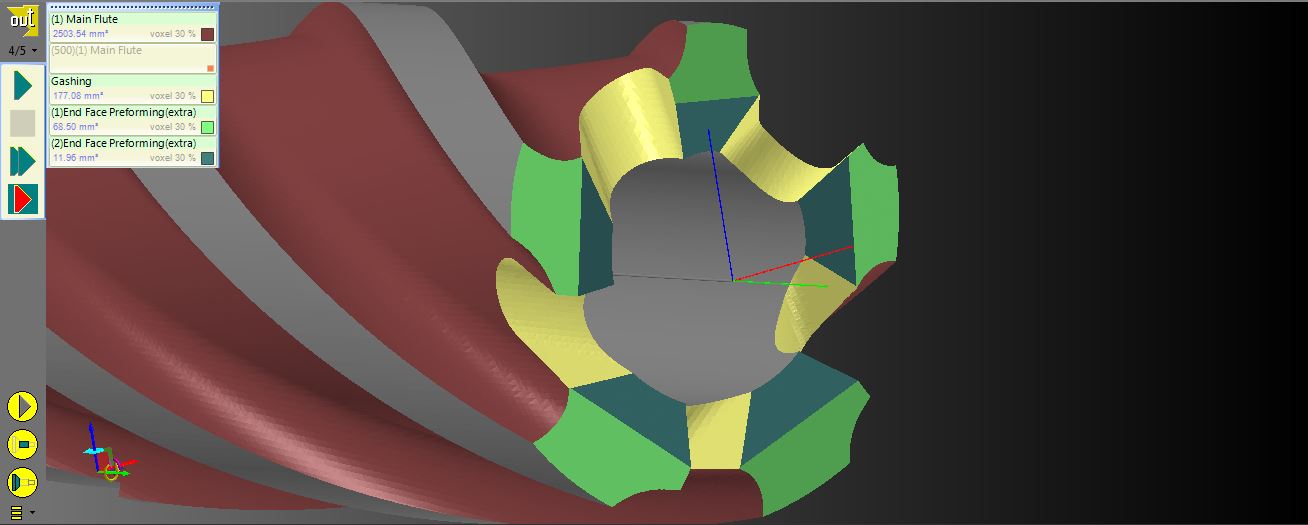

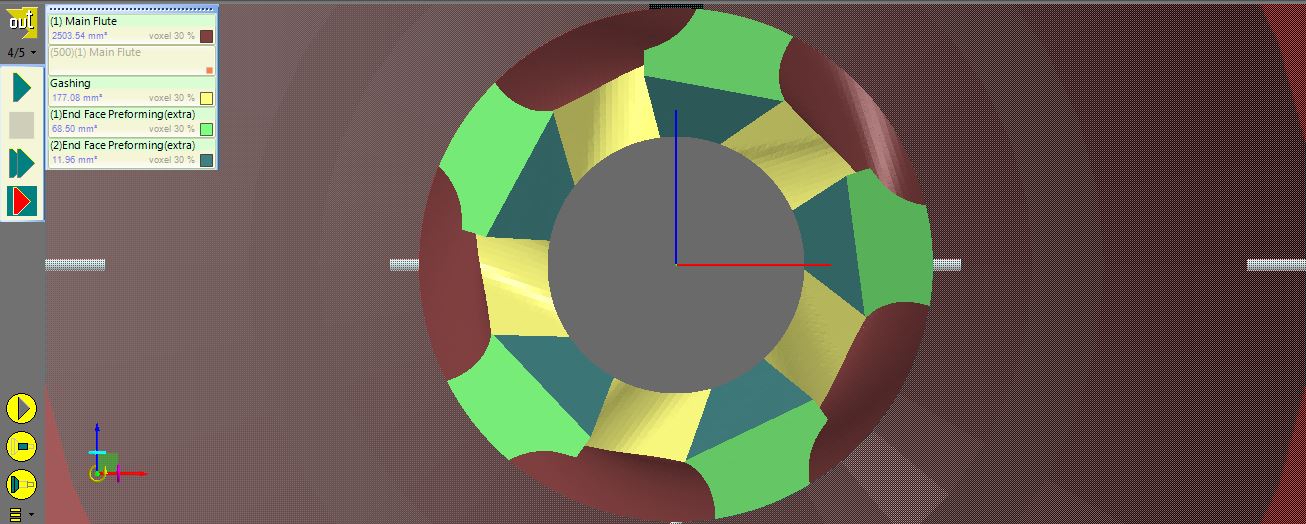

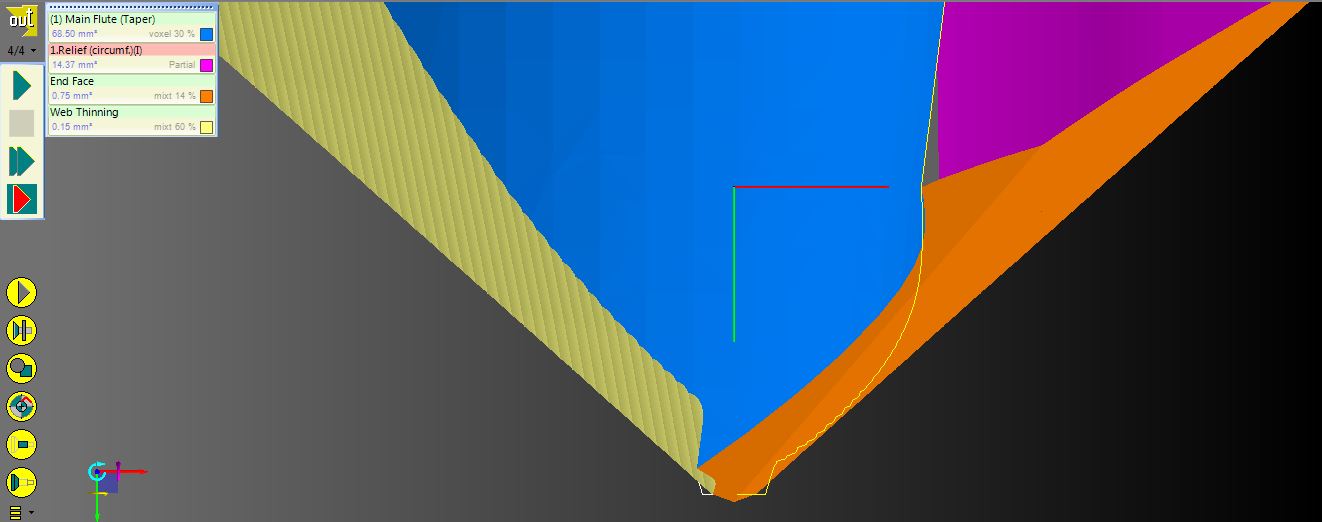

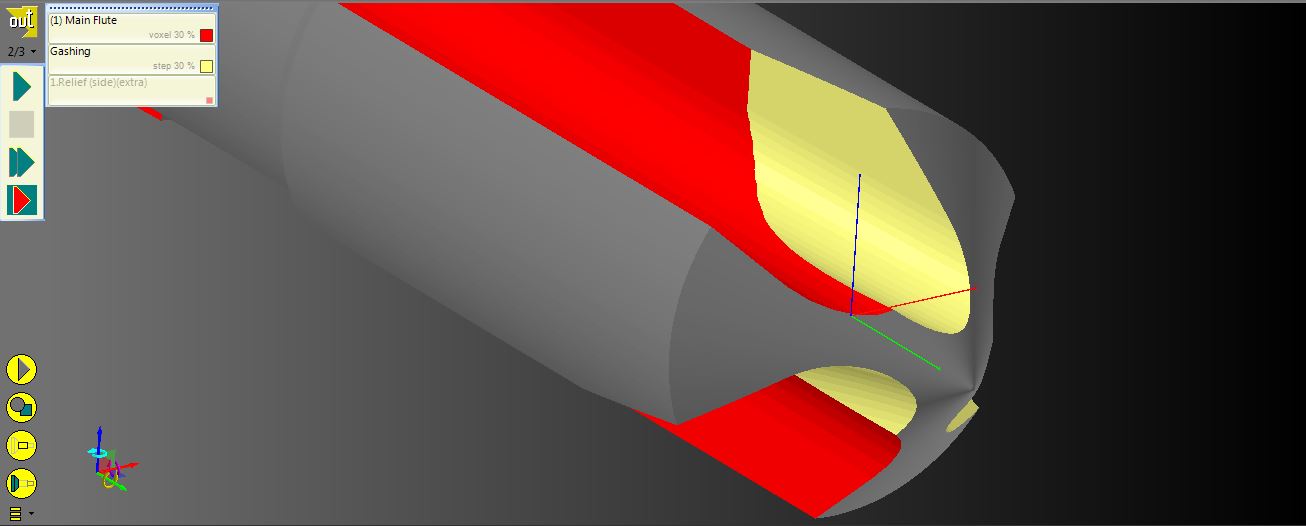

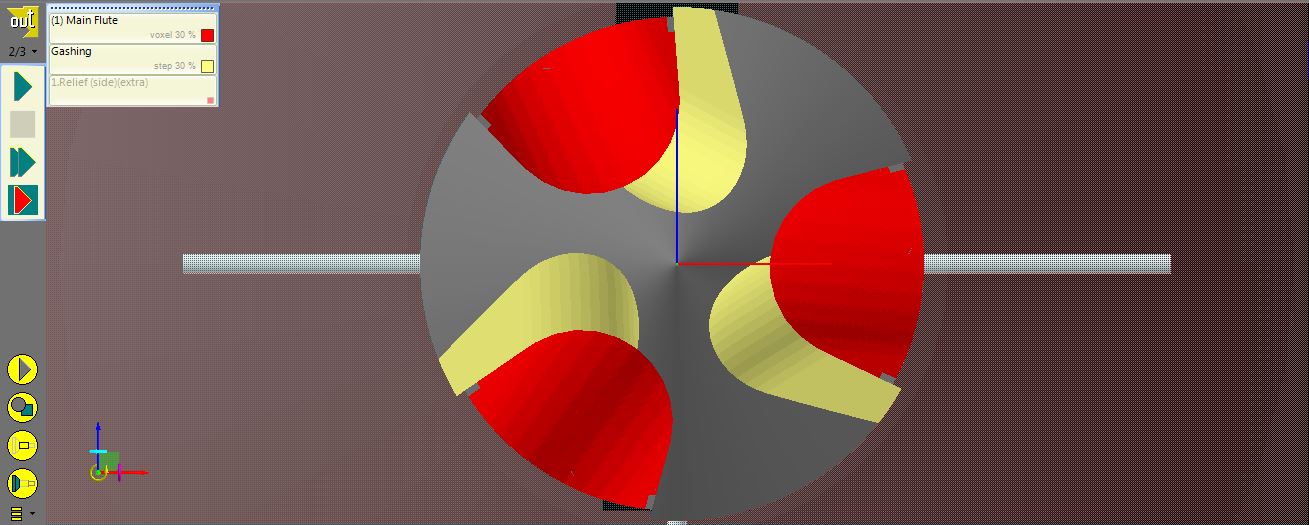

The machine is installed with the latest FANUC CNC with a 1-in-1 million defect rate and a 15″ Panel-i CNC include software to store 100,000 part programs. The software is the world’s first dedicated Windows based software with 2D and 3D simulations and grinding of various short or long chamfer, back taper for normal and high helix chamfers.

For further information regarding ITM’s Chamfer grinders, contact us at (386) 585-8166

Fanuc robot ready to work lights out 24/7

One of three UODGs at an Italian tap manufacturer

ULTRA PRECISION, RELIABLE, NON-STOP CHAMFER GRINDING

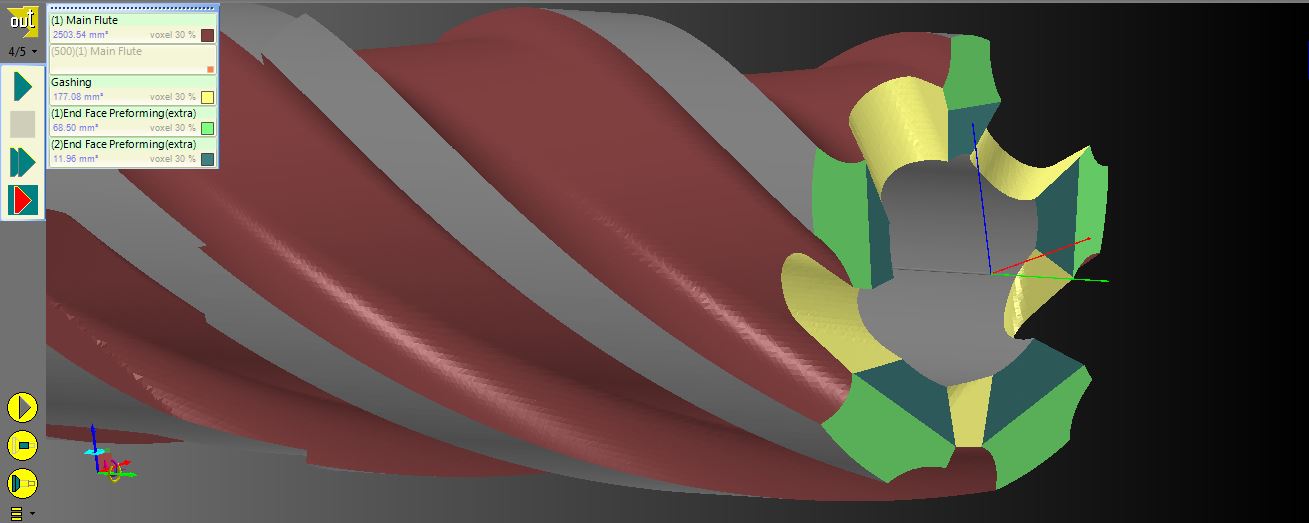

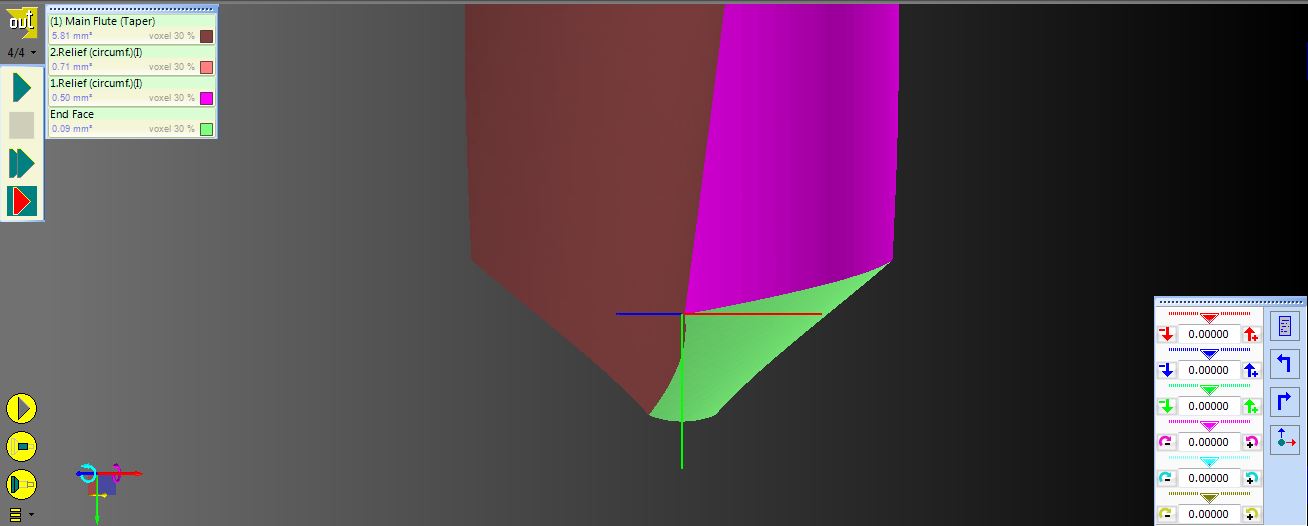

Chamfer grinding M16 tap with long taper

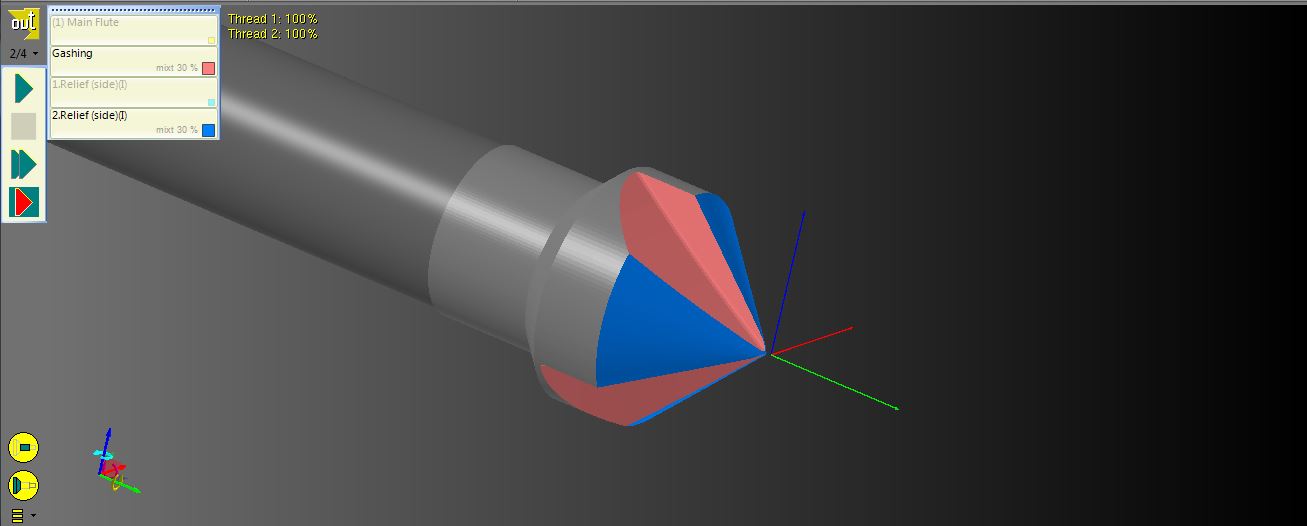

Grinding main chamfer on a M12 tap

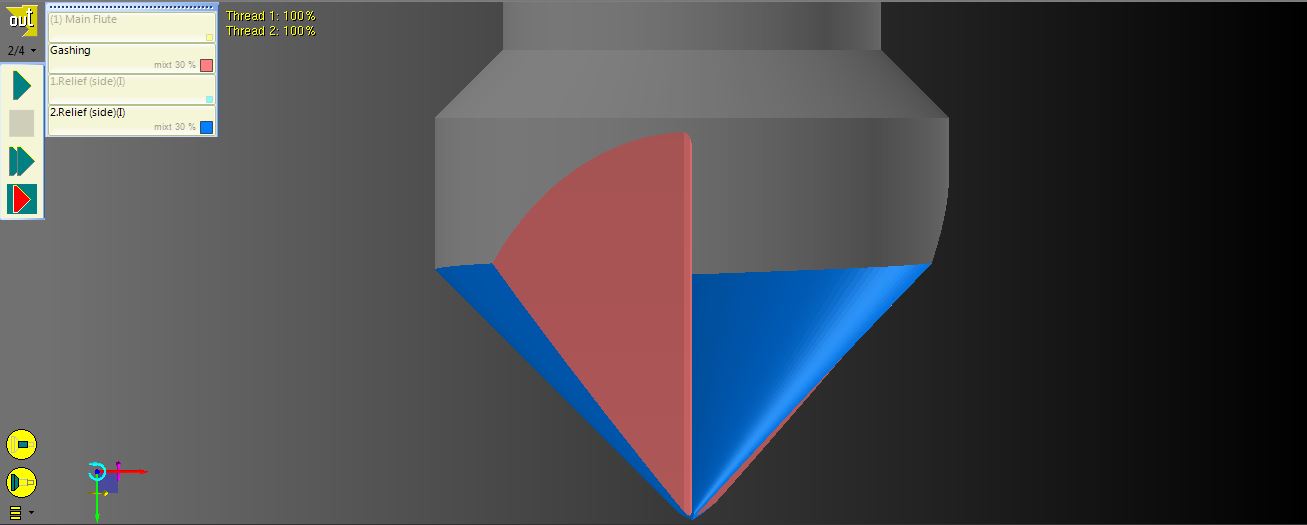

Chamfer grinding M12 right or left hand tap

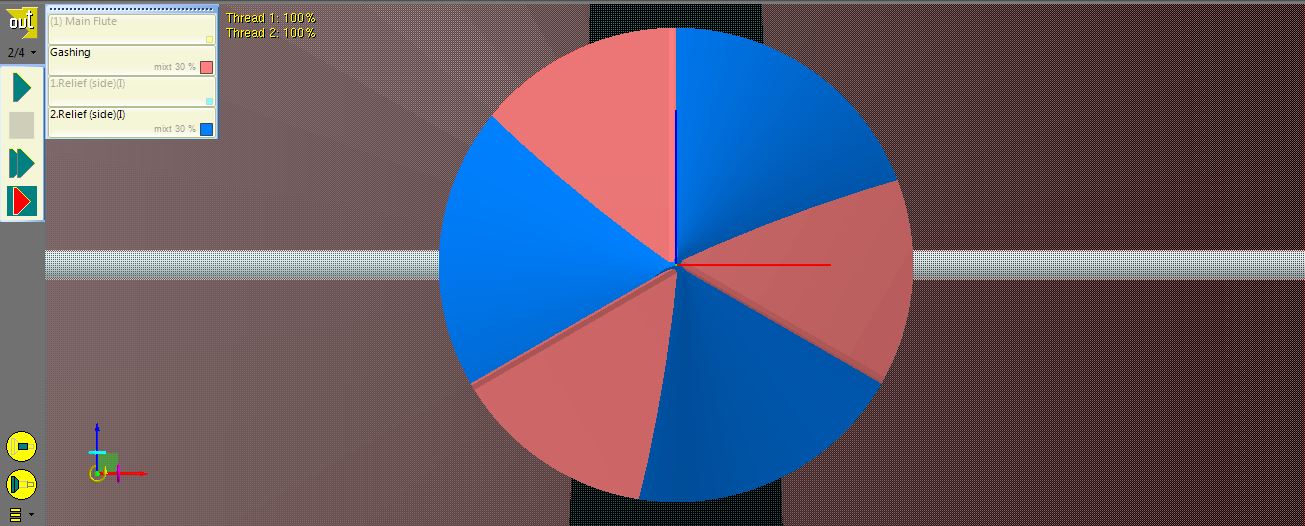

Chamfer grinding M2 right hand spiral flute tap

FLEXIBLE, EFFICIENT & USER FRIENDLY

SOFTWARE APPLICATIONS / GRINDING OPERATIONS

- Taps: Chamfer With Or Without Relief, Square, Front And Back Chamfer

- Countersinks: Cone Relief & OD, Tapered Shank

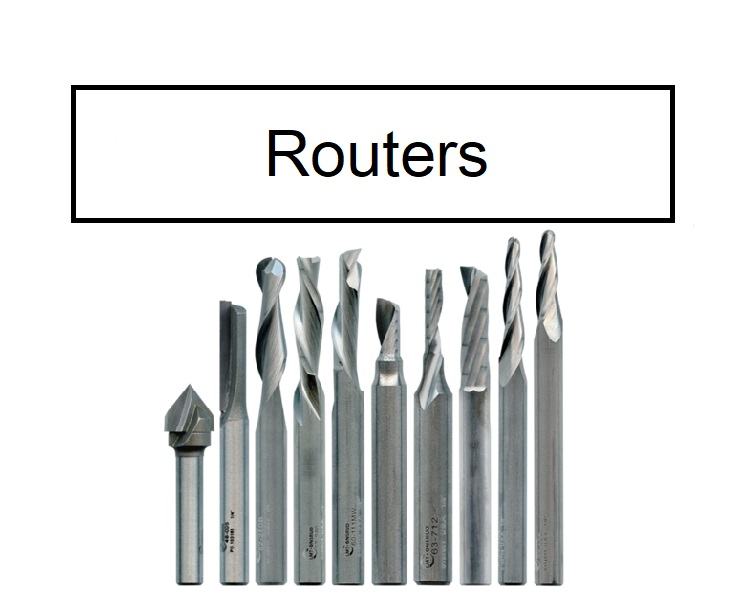

- Router bits: OD Relief, Square, Tapered, Front And Back Chamfer

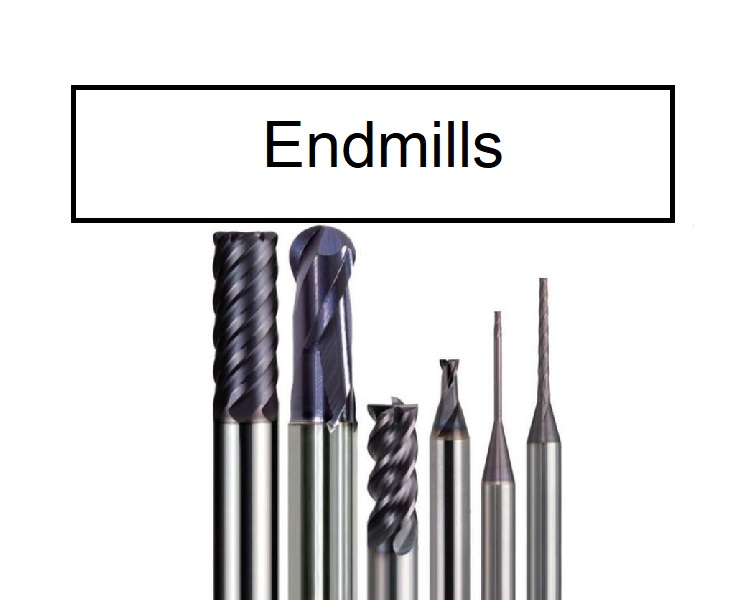

- Endmills: Cone Relief & OD, Tapered OD, Front And Back Chamfer

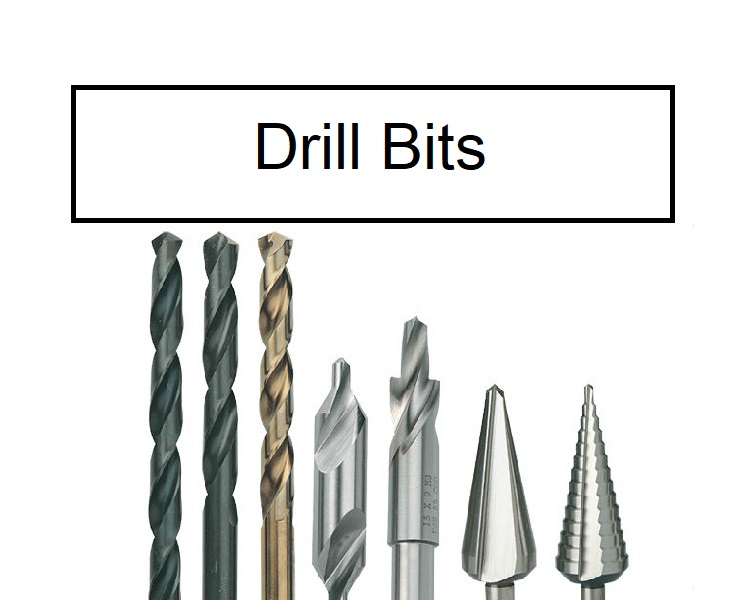

- Twist Drill: Cone Relief & OD, Tapered OD, Front And Back Chamfer

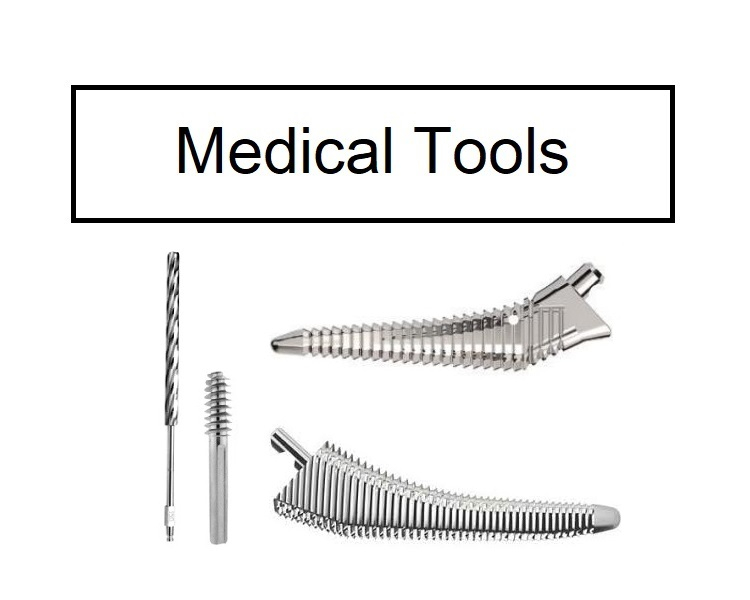

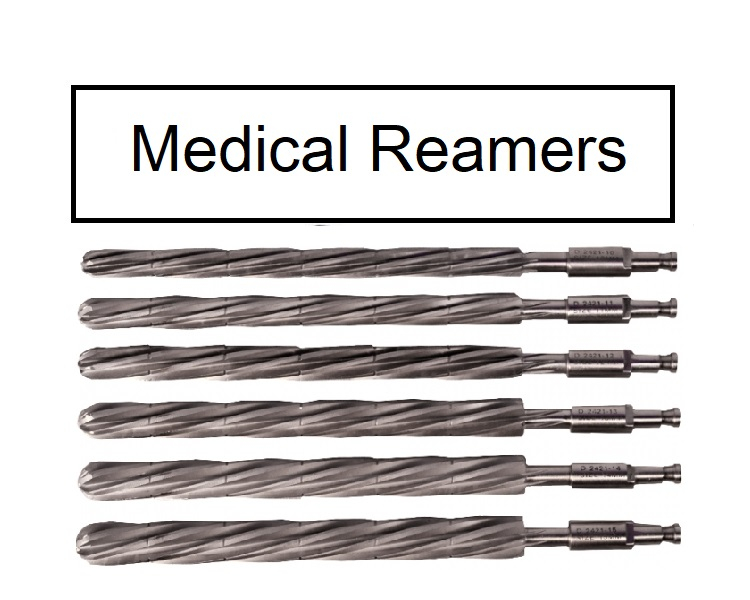

- Medical Device: Reamer, Burrs, Implant, Square, Front And Back Chamfer

- Reamer: OD Relief, Chamfer, Tapered OD, Tapered, Front And Back Chamfer

- Step Drill: OD axial relief, OD Radial Relief, Tapered OD, Front And Back Chamfer

- Counterborers: OD Relief, Tapered OD, Front And Back Chamfer

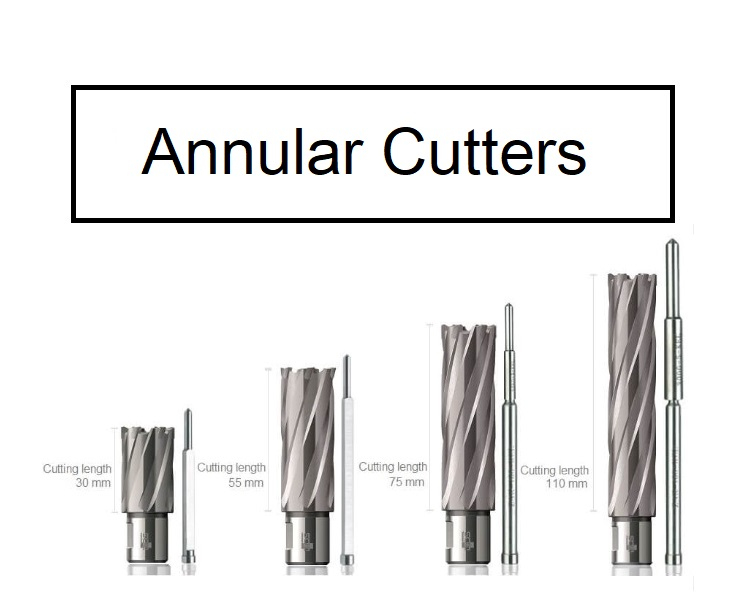

- Annular Cutter: OD Relief, Tapered OD, Front And Back Chamfer