MODEL: FPG – FORM AND PEEL GRINDER

PEEL SERIES

ITM holds over 30 patented machine designs

FLEXIBLE HIGH VELOCITY O.D. GRINDER FOR MULTIPLE STEP PROFILES

A NEW FORM OF O.D. GRINDING

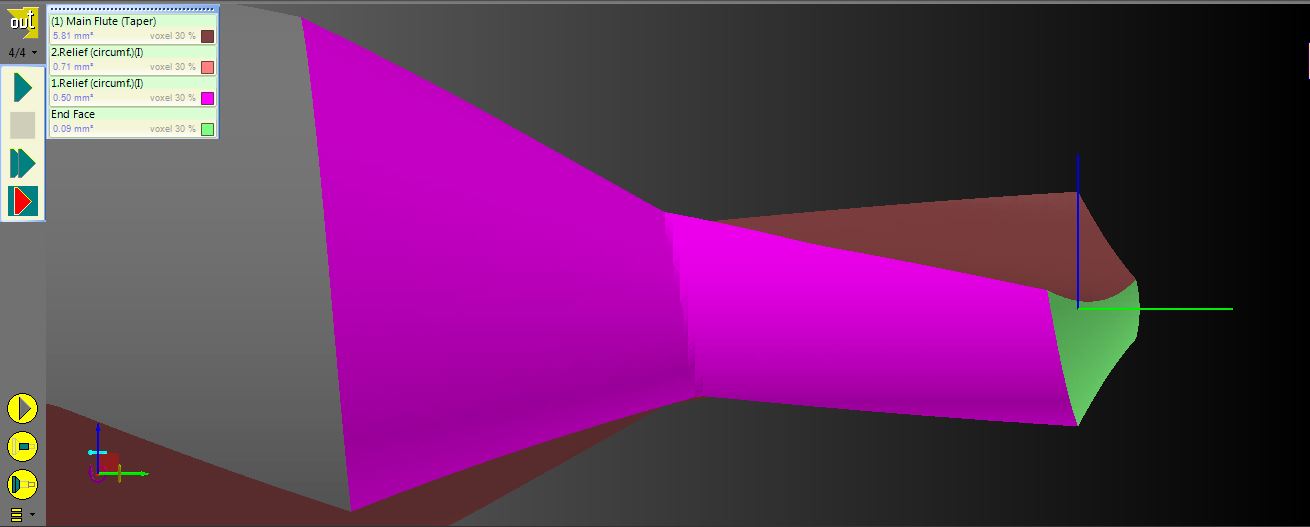

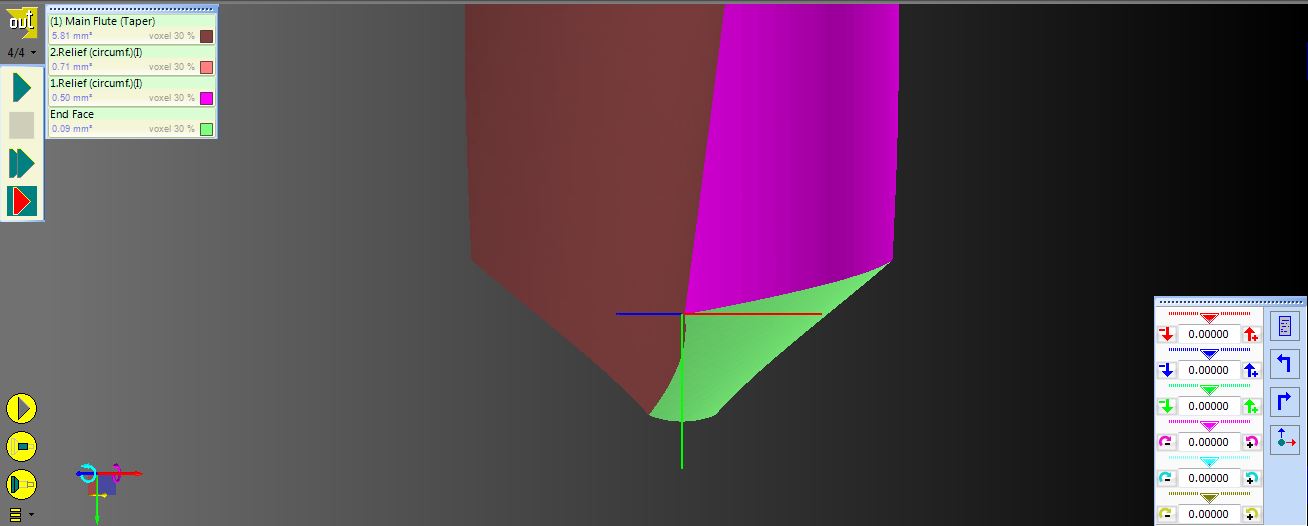

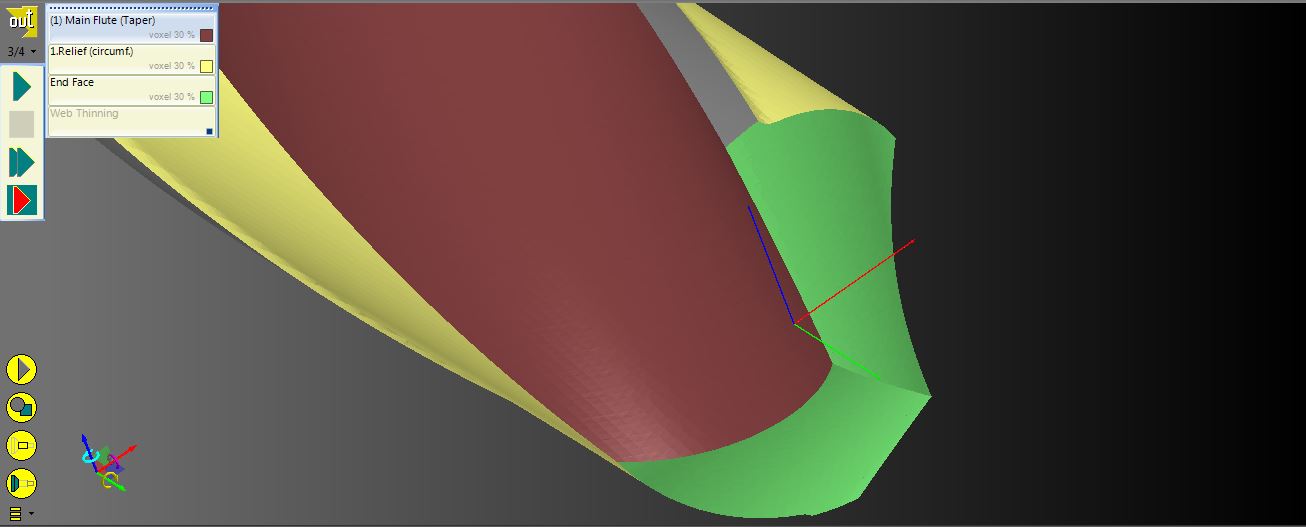

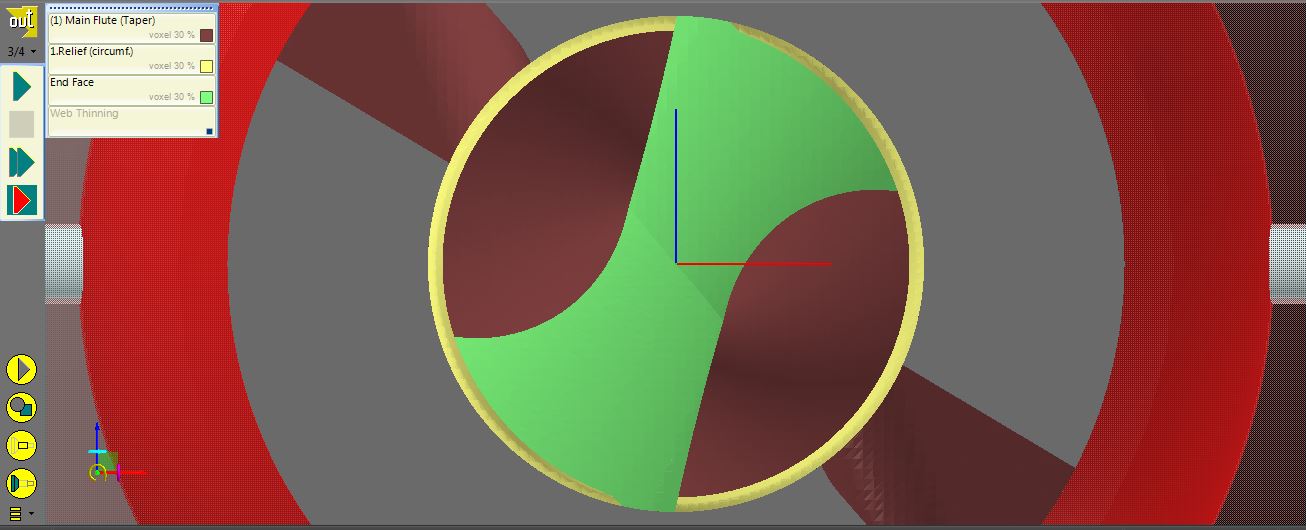

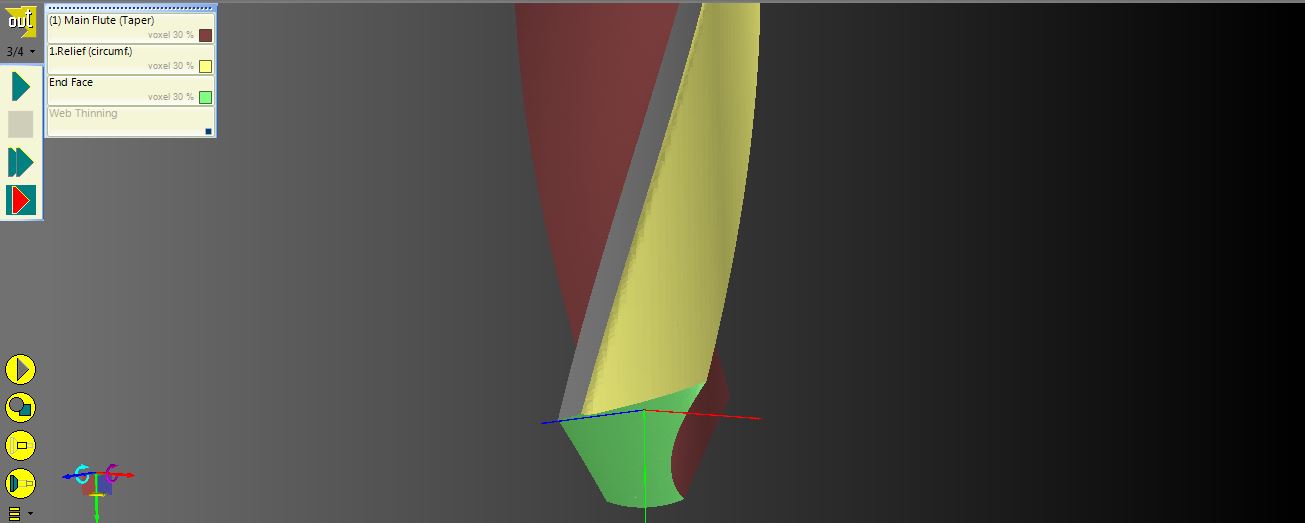

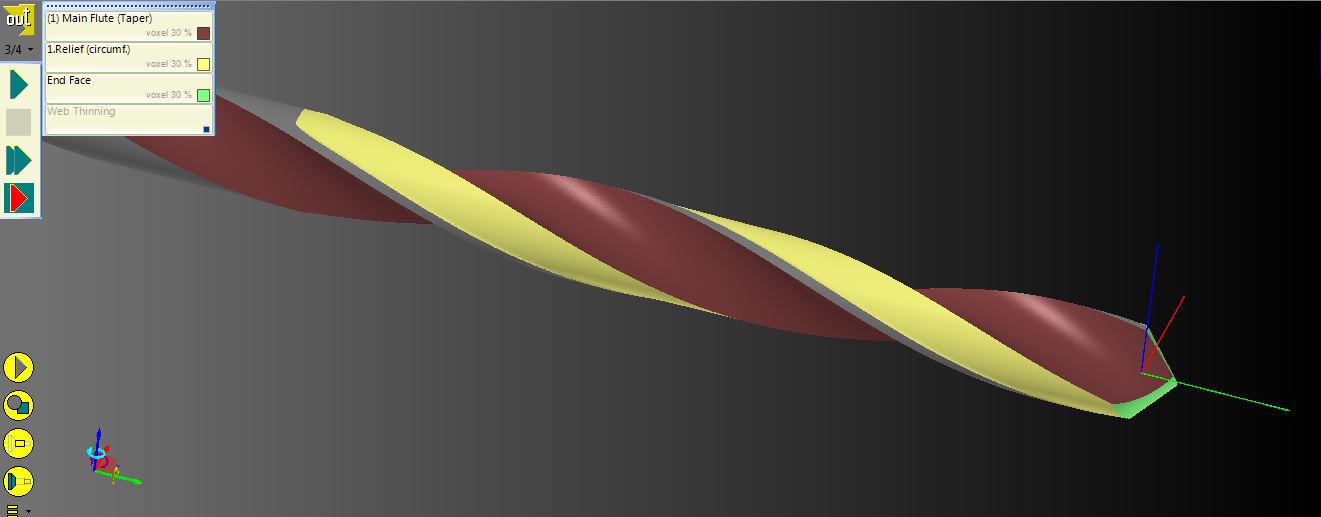

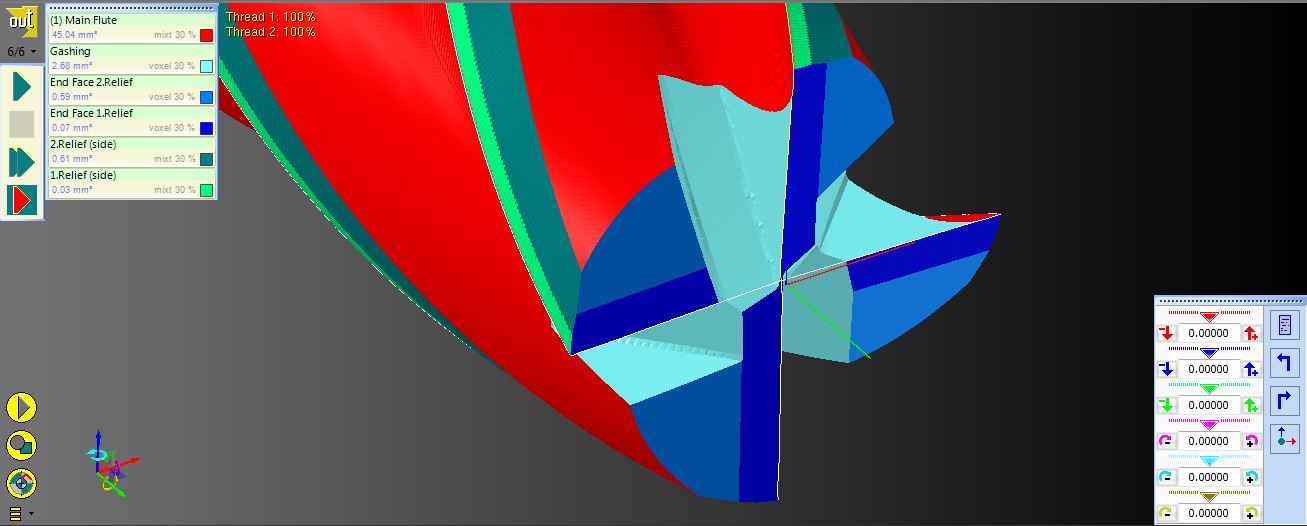

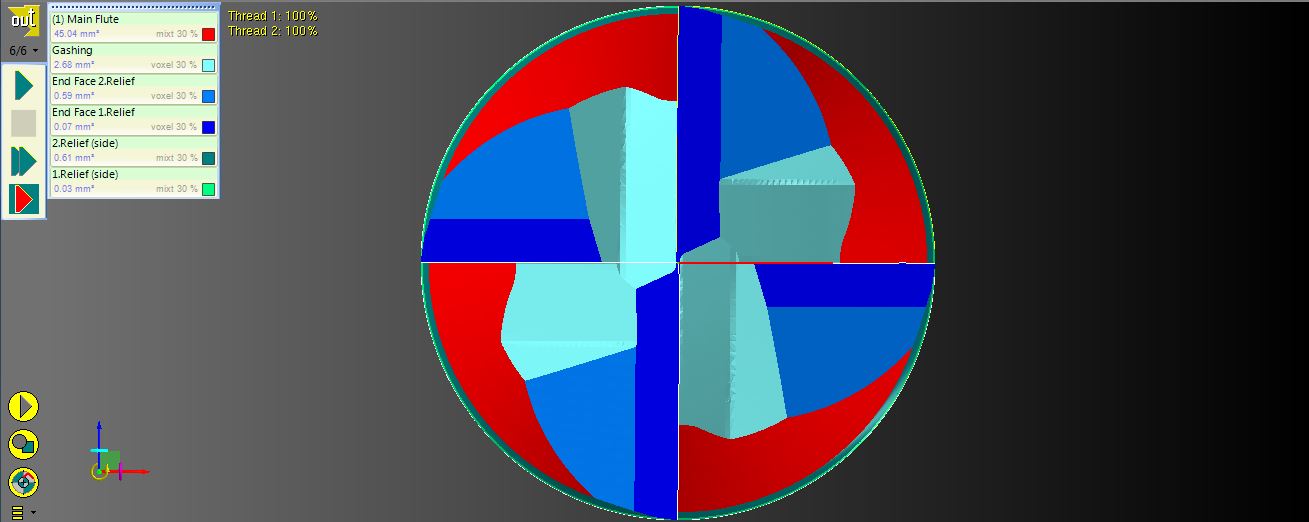

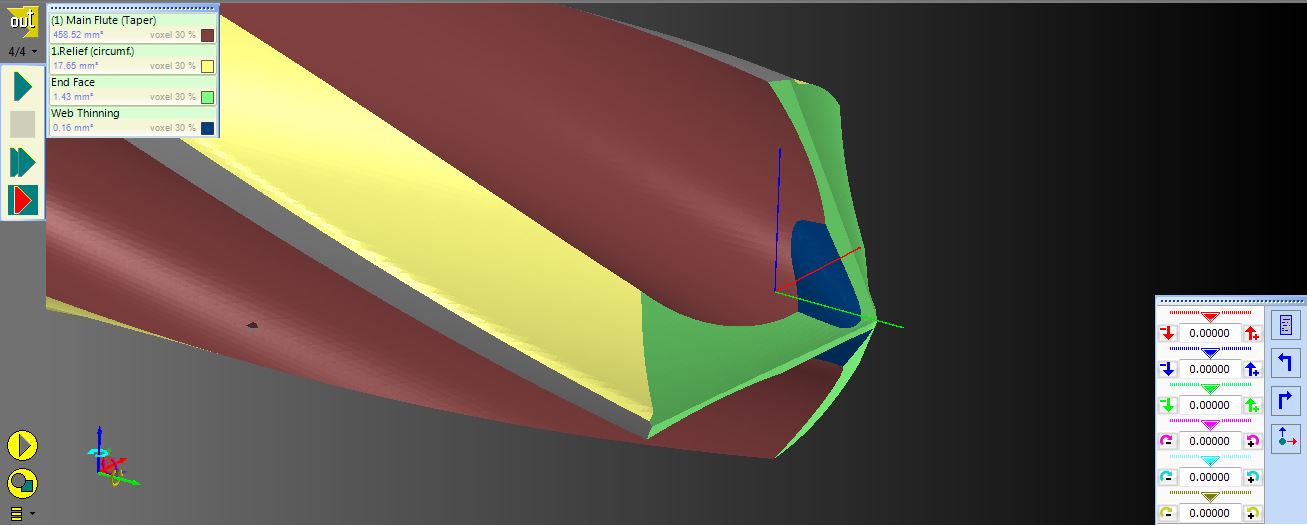

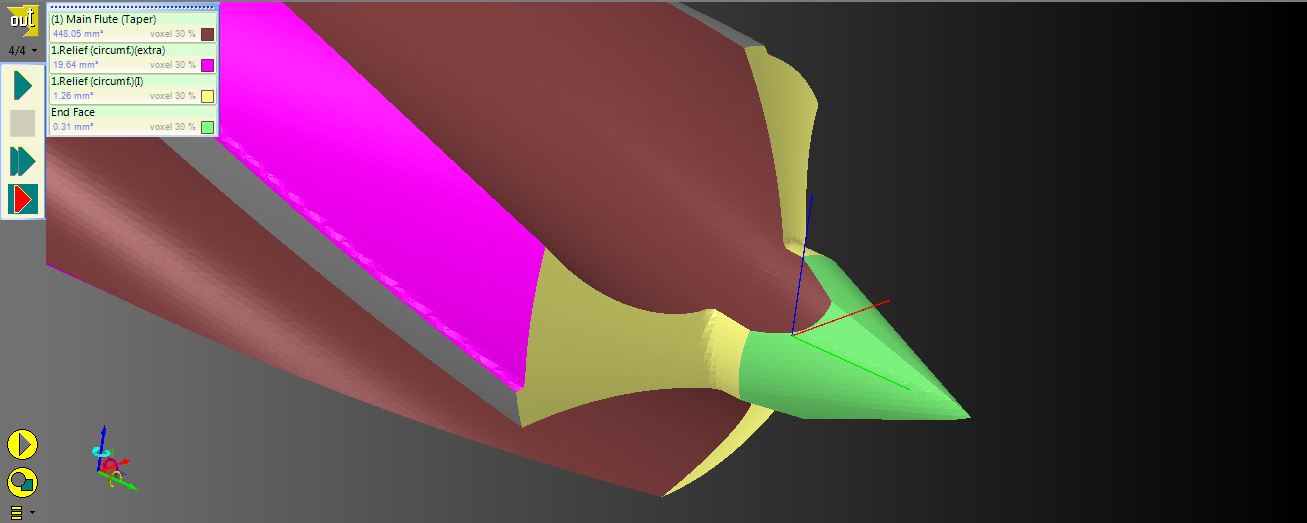

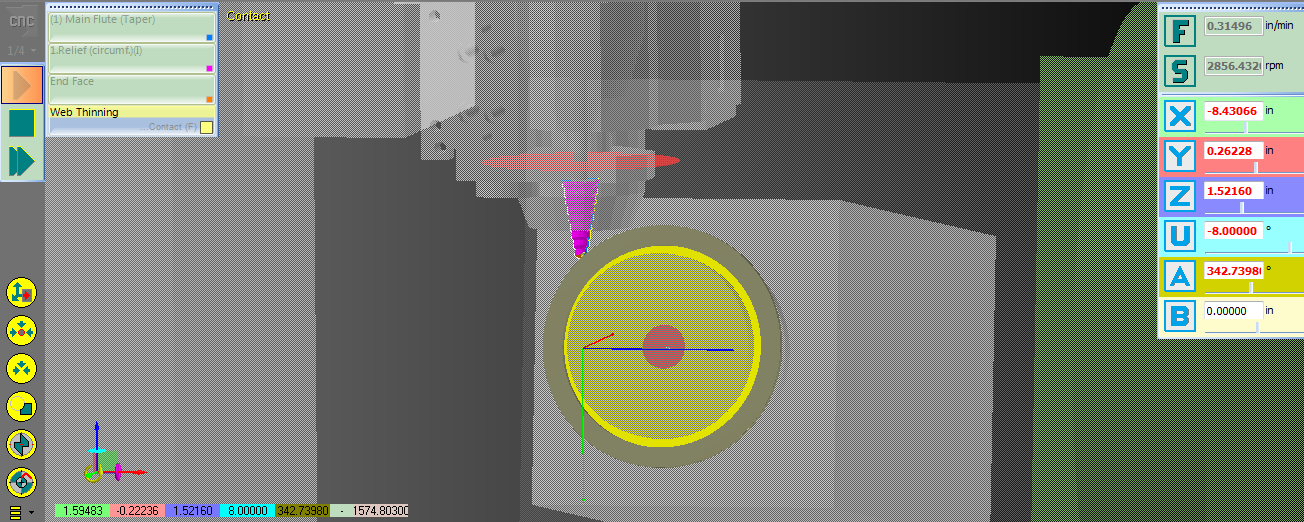

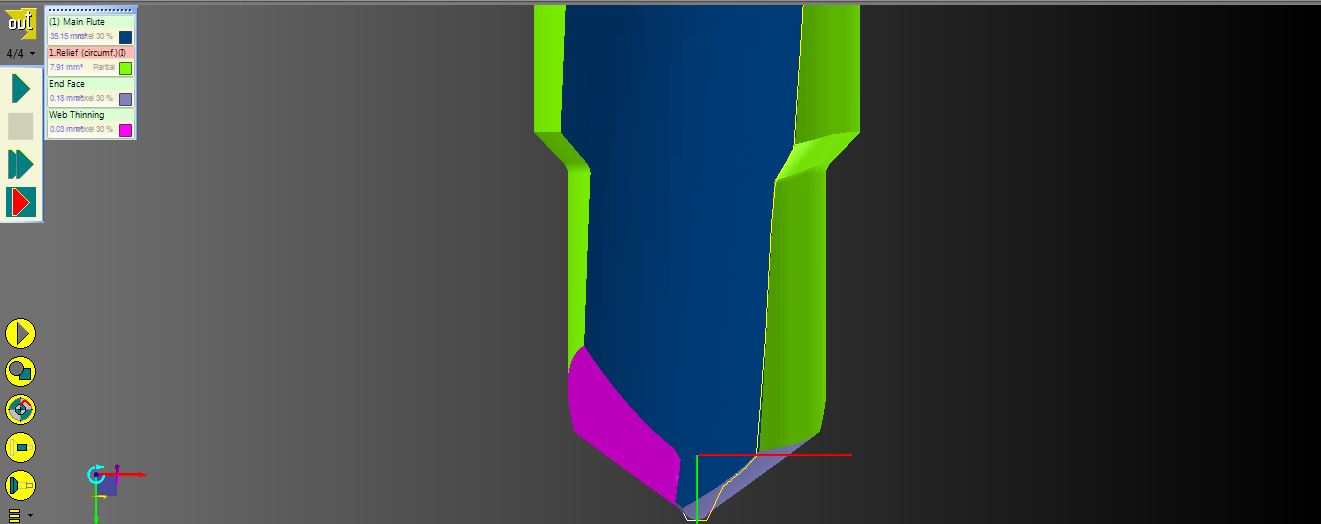

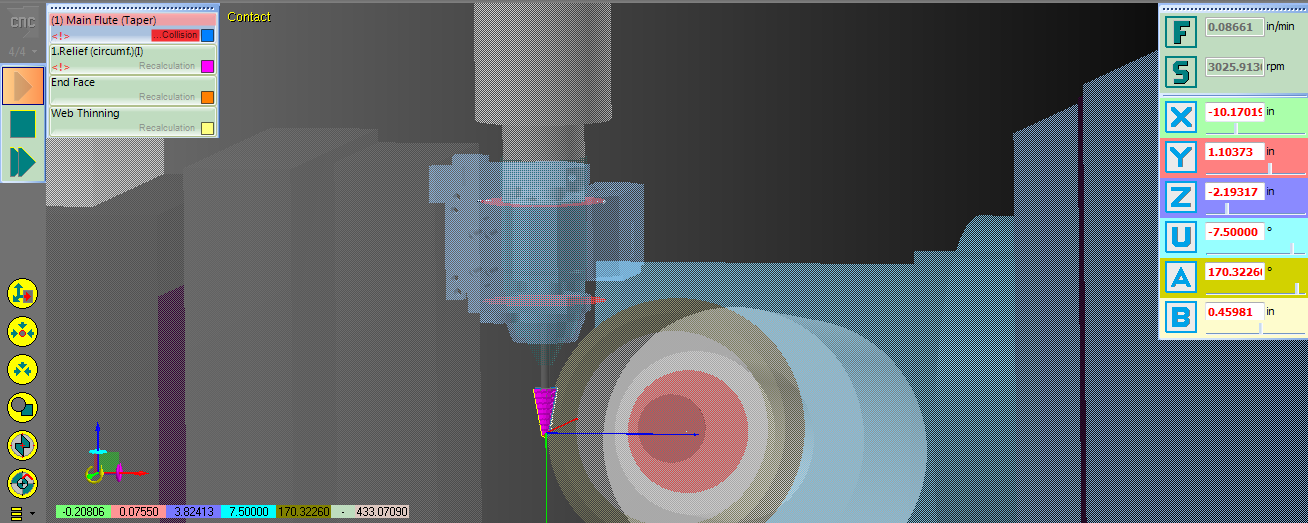

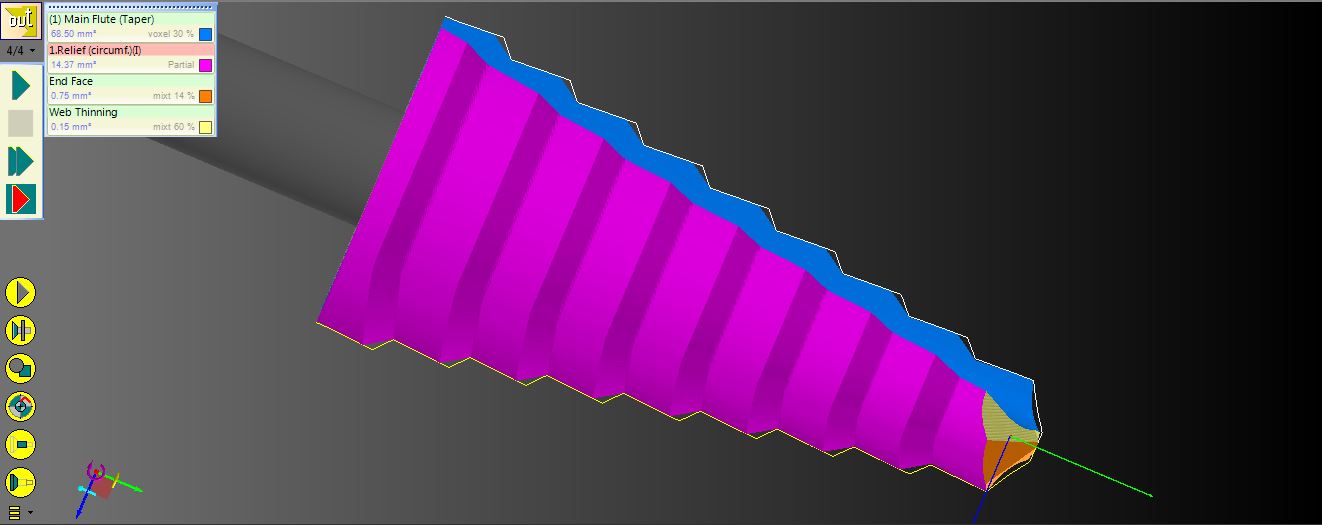

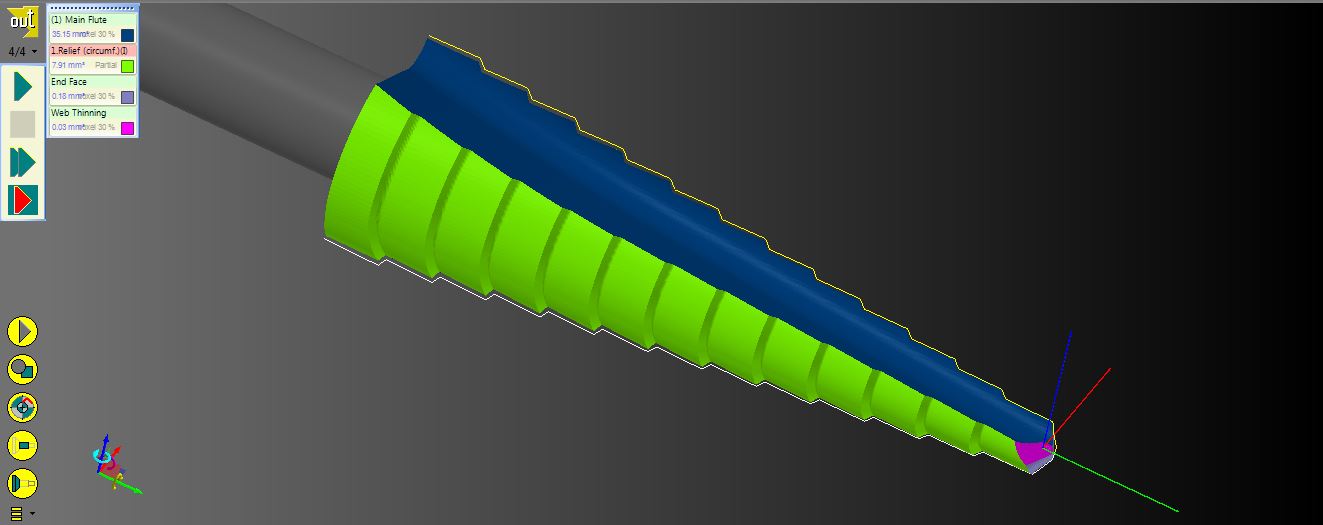

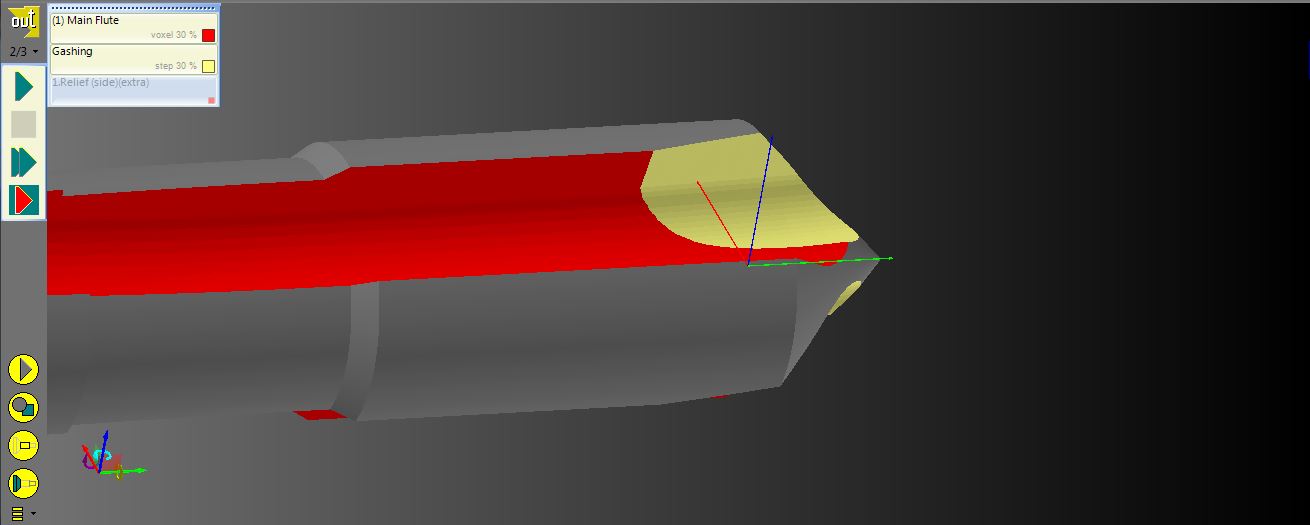

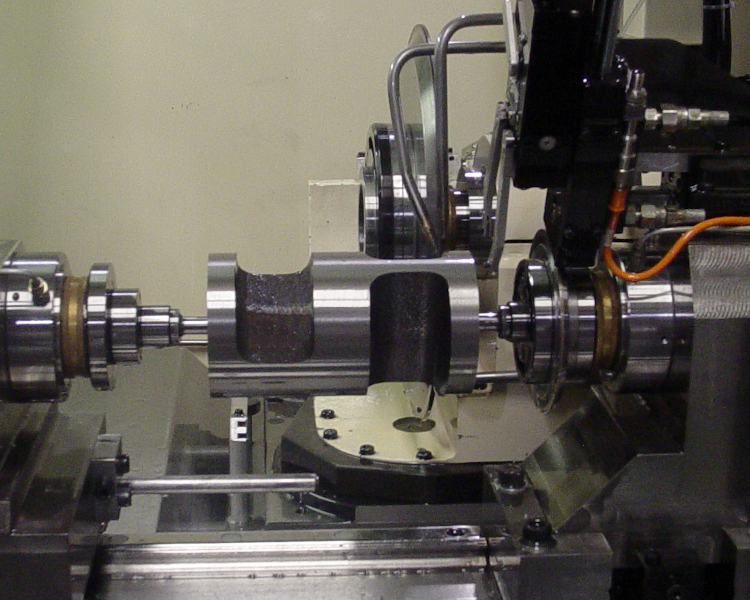

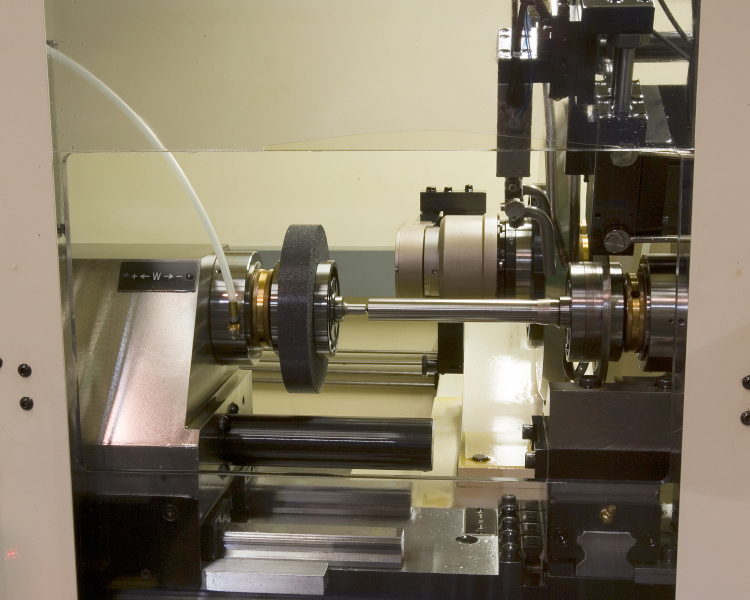

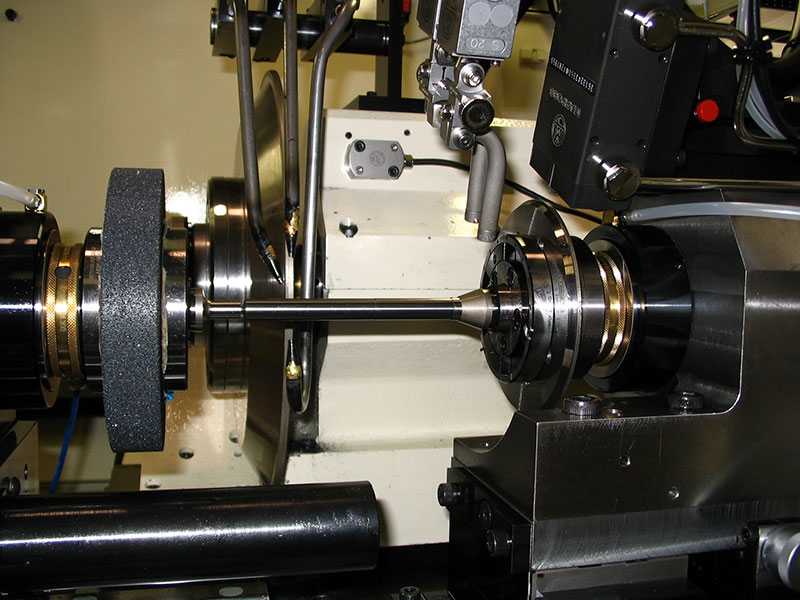

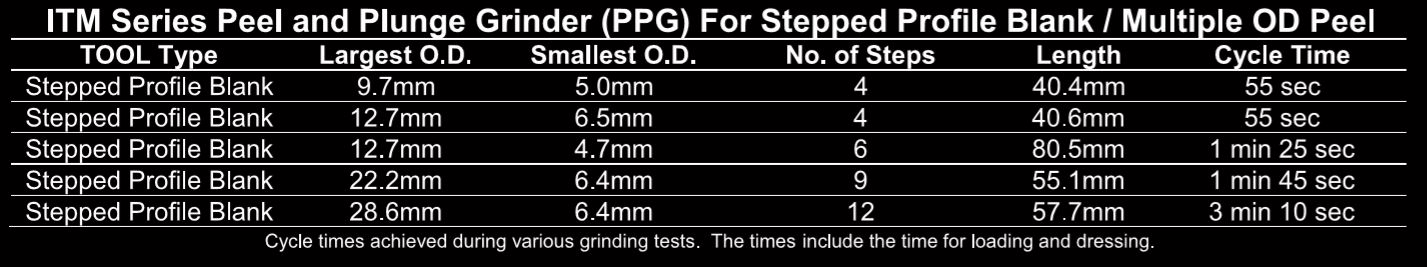

Superior cutting tools with tight tolerances must be produced from properly prepared blanks. In order to ensure quality control and avoid the cost of purchasing expensive blanks, many customers prefer the advantages of producing their own blanks in high production batches with high precision accuracy. ITM’s PPG is a high-performance peel grinder developed for the grinding of cylindrical or tapered parts with multiple steps or profiles, in both carbide and HSS materials.

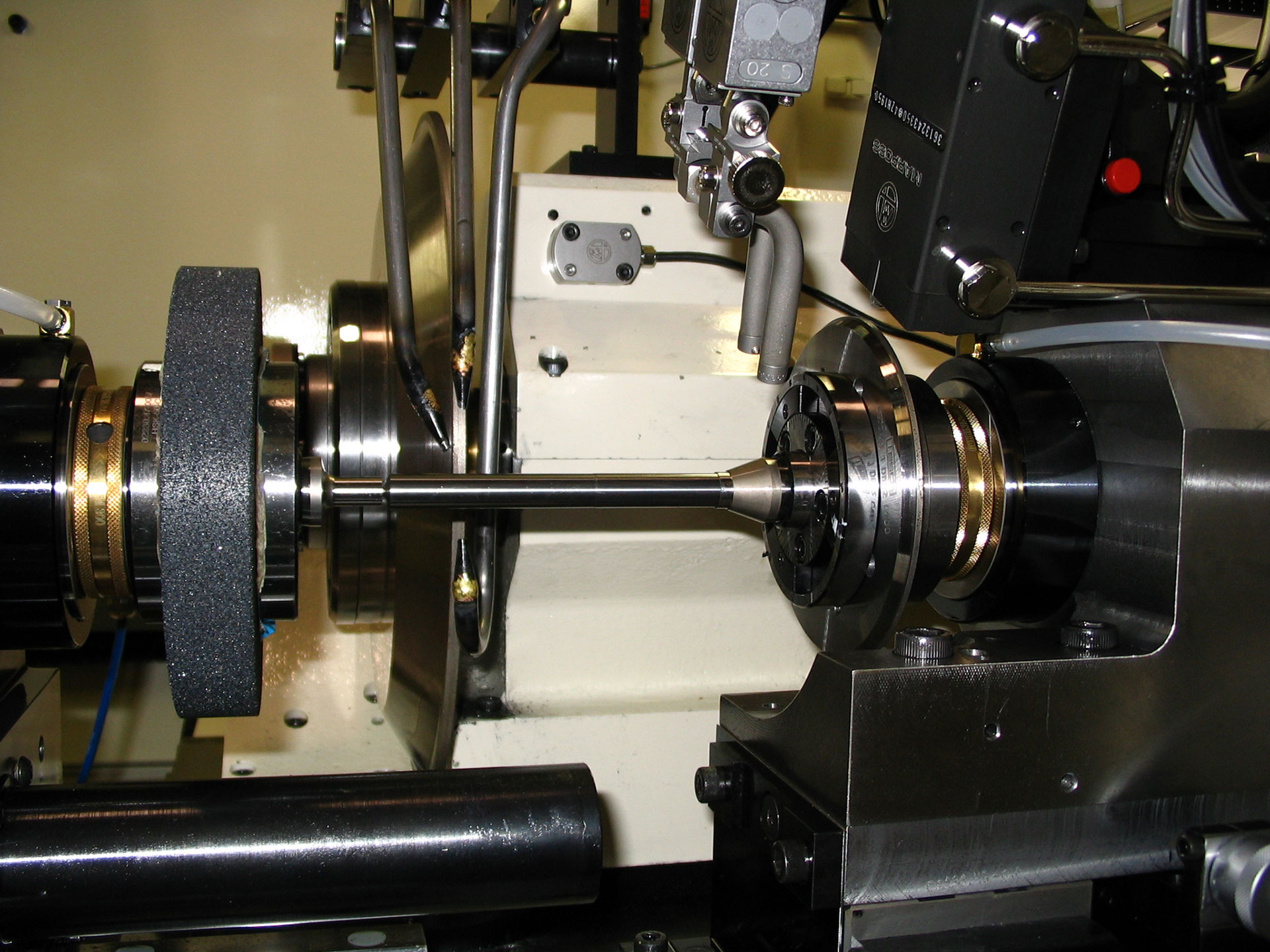

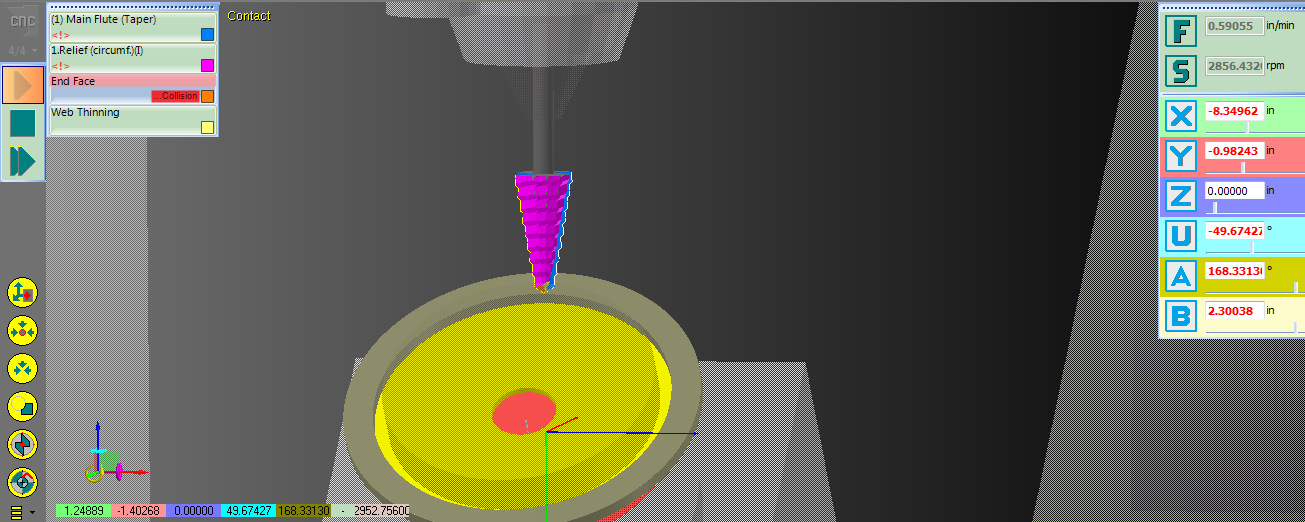

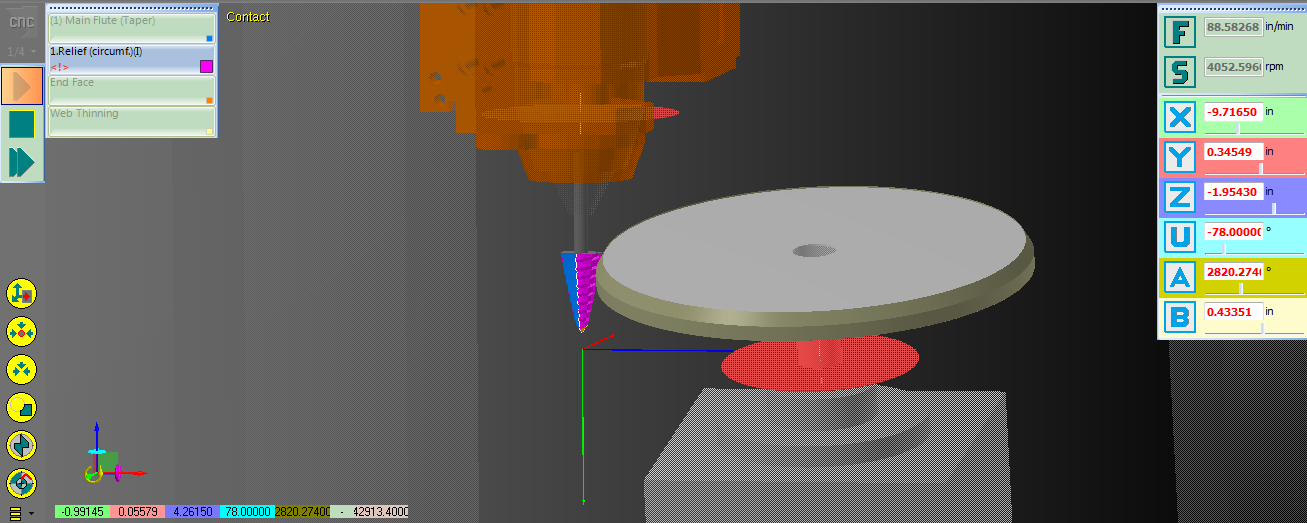

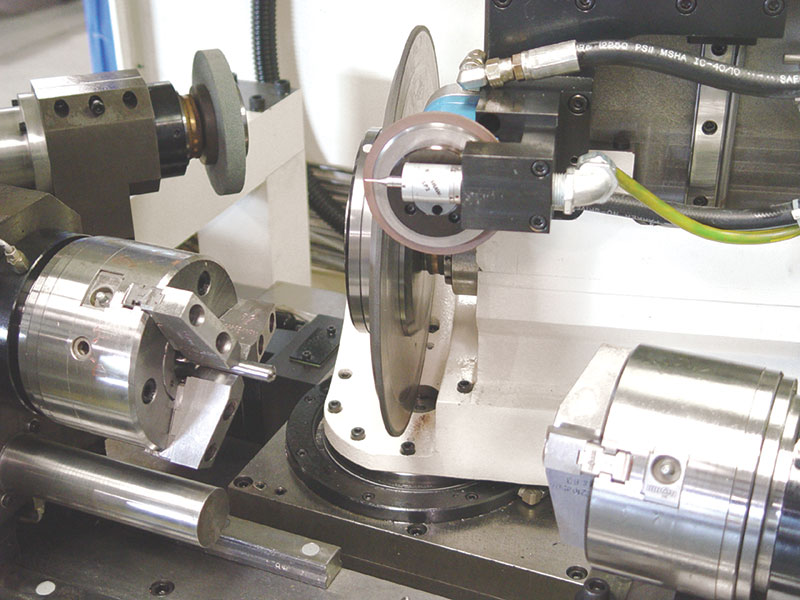

To allow for the tightest tolerances of 1-micron repeatability, the parts are clamped between high precision centers which allow grinding along the complete part length without the necessity of re-clamping. The centers can be mounted to spindles that rotate the parts with speeds up to 5,000 rpm. This arrangement eliminates the usage of driving dogs because the taper of the centers delivers enough driving force, especially when both sides of the part are driven. However, various driving options are available if the force of the centers alone is not sufficient for certain applications.

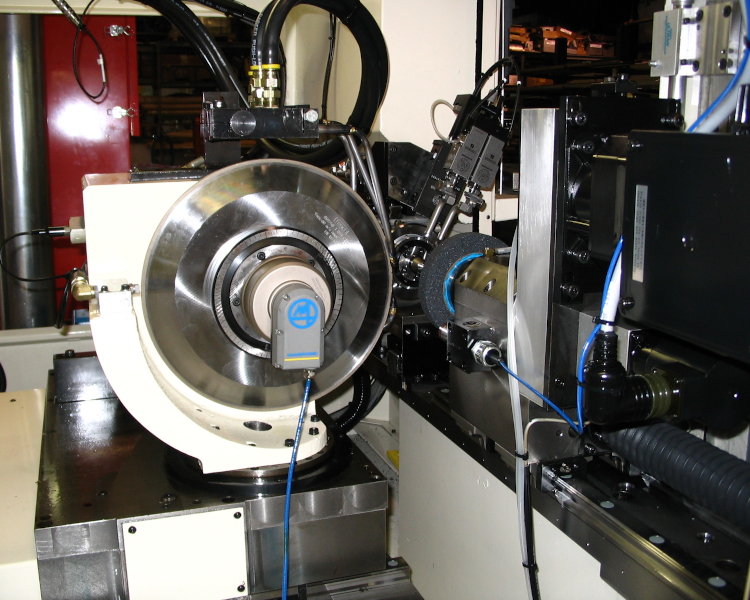

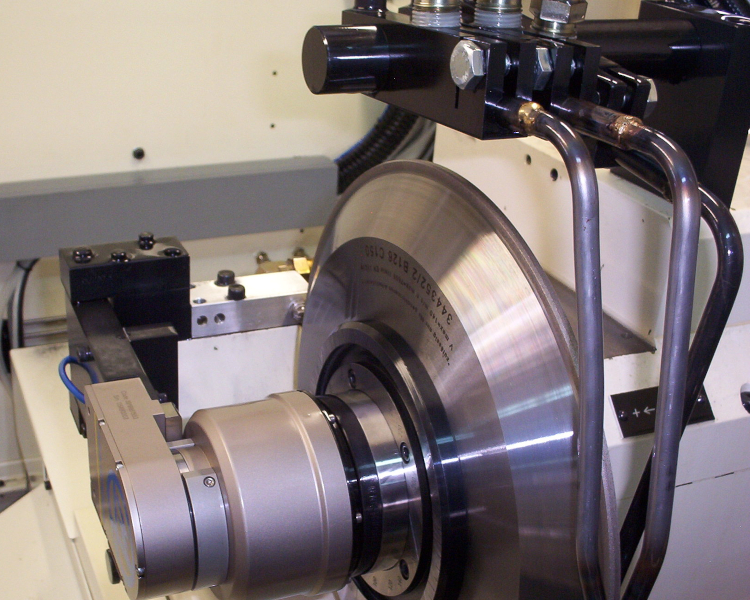

PPG can be set up to rough and finish grind multiple diameters on parts with very efficient peel grinding, or to finish grind with traditional plunge and oscillate grinding to achieve final surface finishes and tolerances. To achieve tighter tolerances, optional high precision dimensional gaging can be used in conjunction with the plunge grinding operation. This feature stops the grinding process when the final diameter is reached on the monitored step. The gage can also be utilized as an in-process gage when using peel grinding to remove stock in one or multiple passes. In this set-up, the machine can be programmed to check the part diameter before the final grinding pass and automatically set the correct infeed amount that is needed to reach the desired finish diameter. Only one diameter can be gaged per set-up. However, the gage can be positioned anywhere along the complete part length allowing to control the most critical diameter.

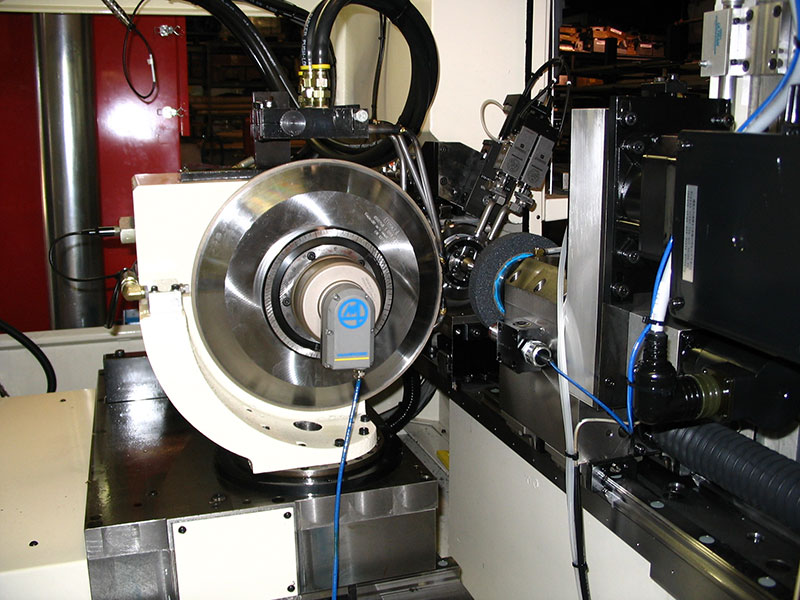

HIGH PERFORMANCE O.D. GRINDER

ITM’s Peel & Plunge Grinder (PPG) was developed for tool grinding cylindrical or tapered parts with multiple steps or profiles. PPG has a 15” screen panel along with an integrated computer interface for ease of use. Machines are built with easy access for wheel and tool changes. First piece tool setup time including wheel change, tool change, software programming is only 10 minutes.

The Peel Grinder is capable of tool grinding materials such as High Speed Steel (HSS) and Carbide. Customers prefer the advantages of producing their own blanks in high production batches with high precision accuracy. Thus, they avoid the cost of purchasing expensive precision blanks.

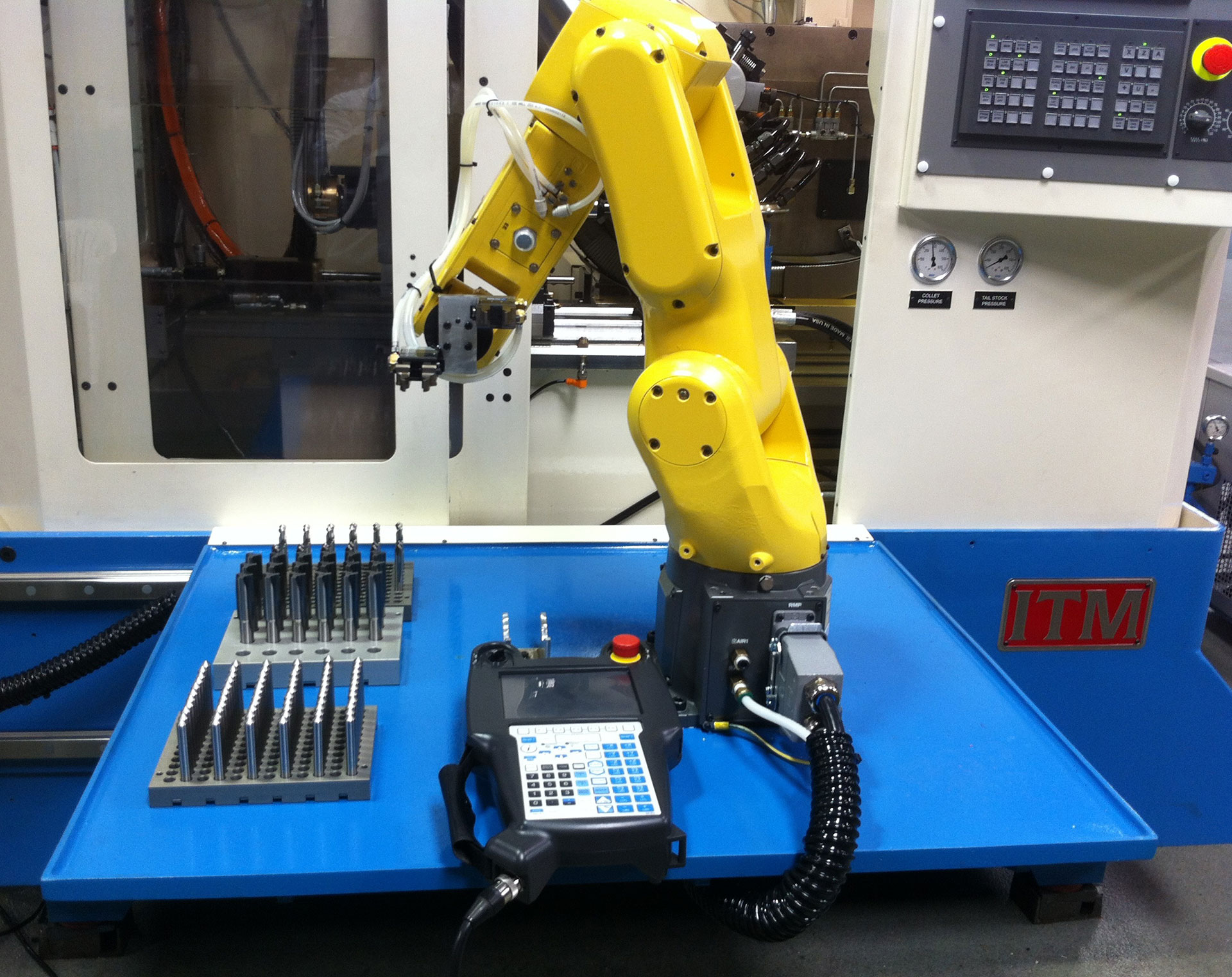

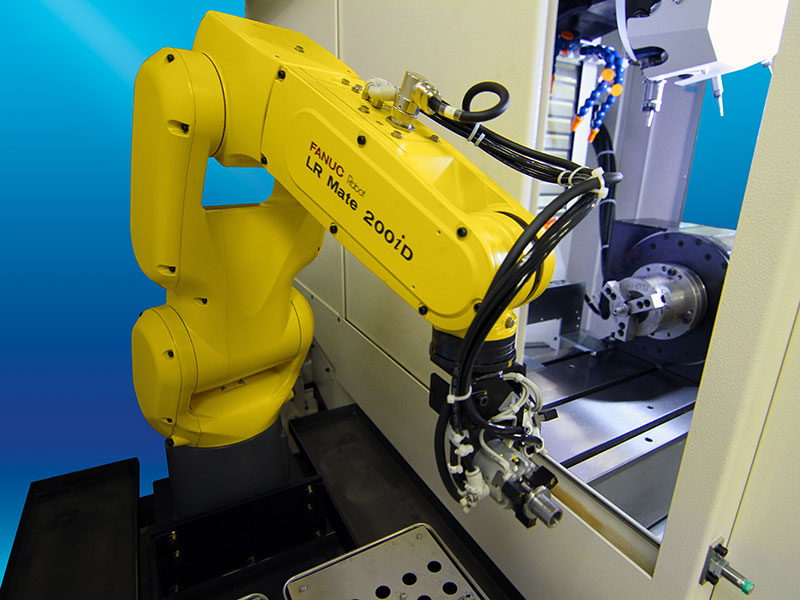

For tool loading and unloading, ITM offers a cassette loading or robotic pick-N-place system. Up to 300 pieces can be pre-loaded in cassettes or pallets for long periods of unattended operation.

For further information regarding ITM’s Peel Grinders and Form Grinders, contact us at (386) 585-8166

ULTRA PRECISION, HIGH PRODUCTIVITY & SHORT CYCLE TIMES

FLEXIBLE, EFFICIENT & USER FRIENDLY

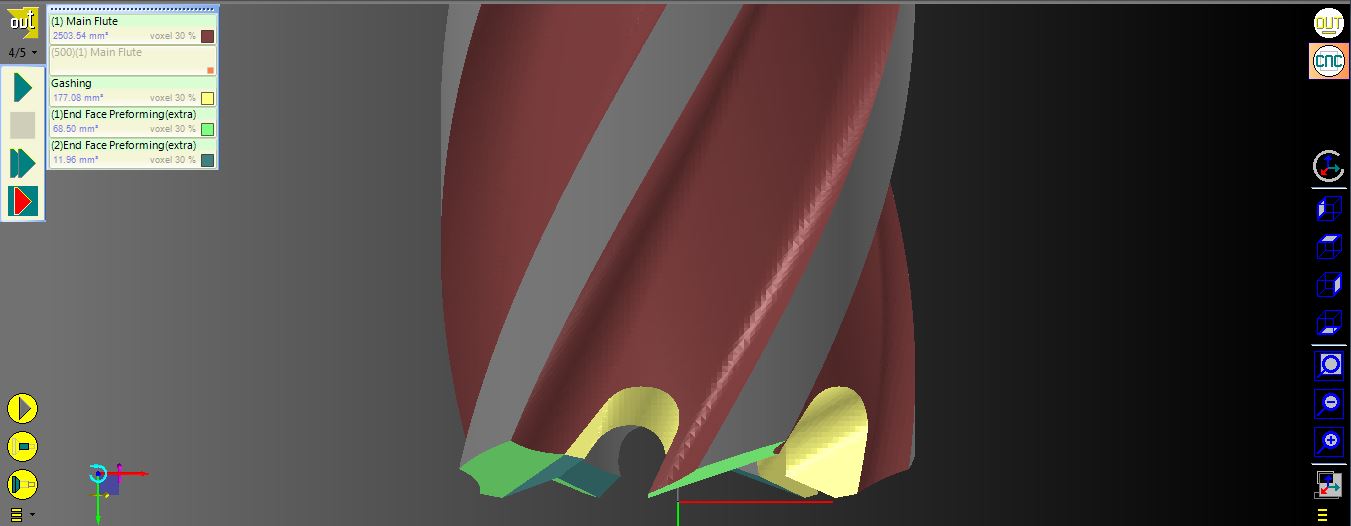

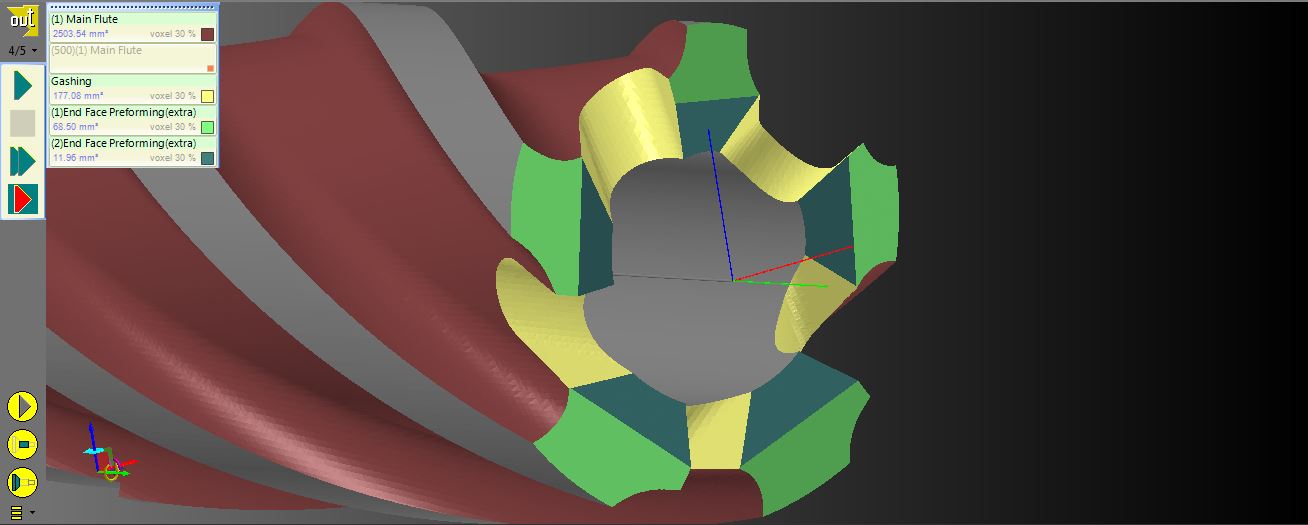

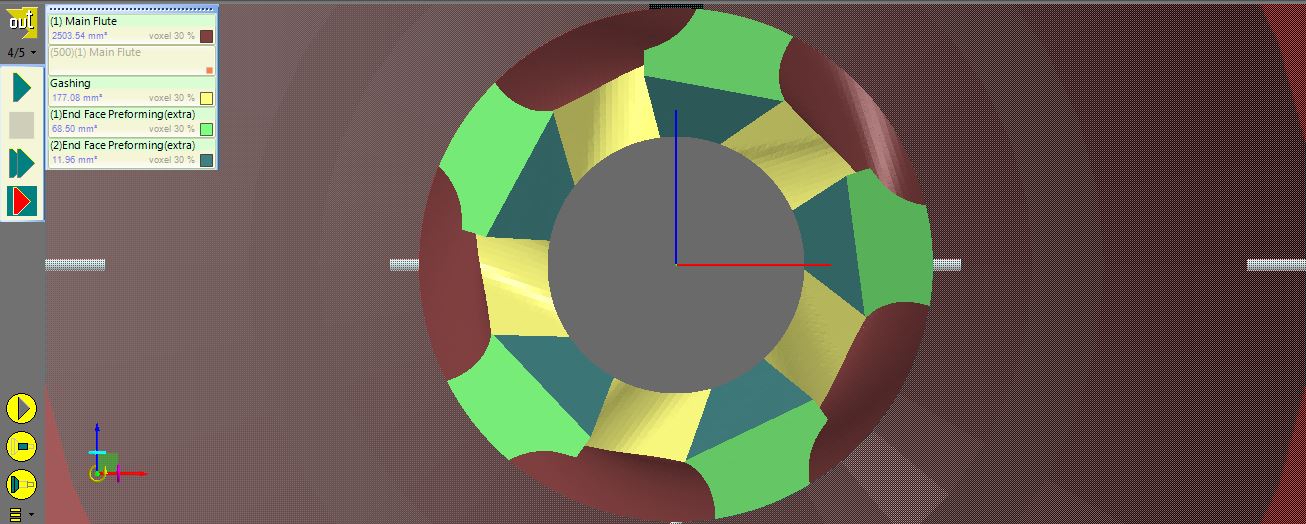

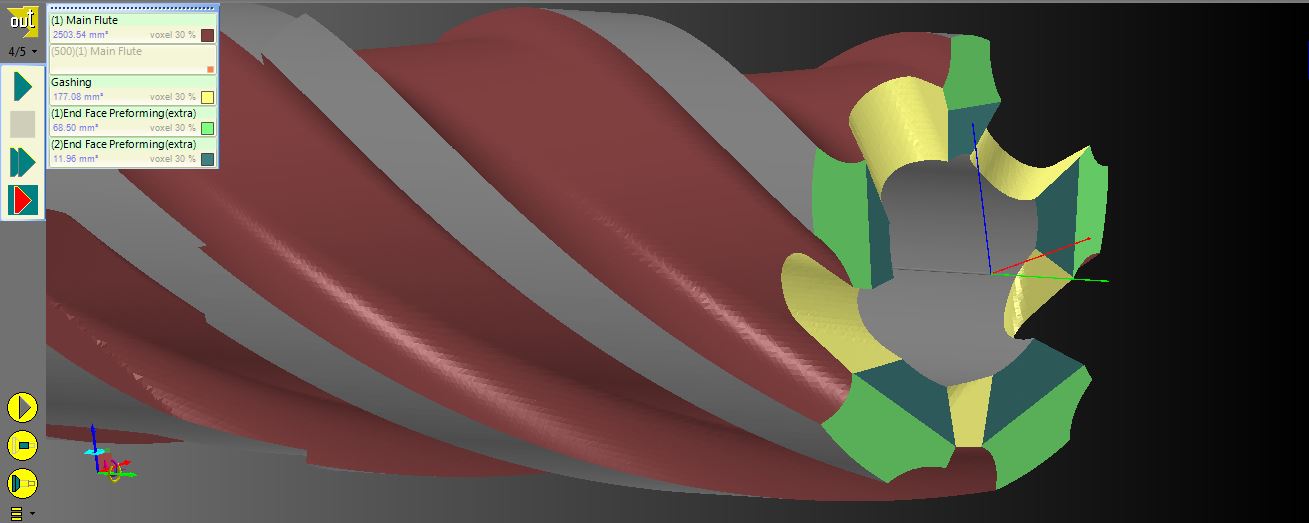

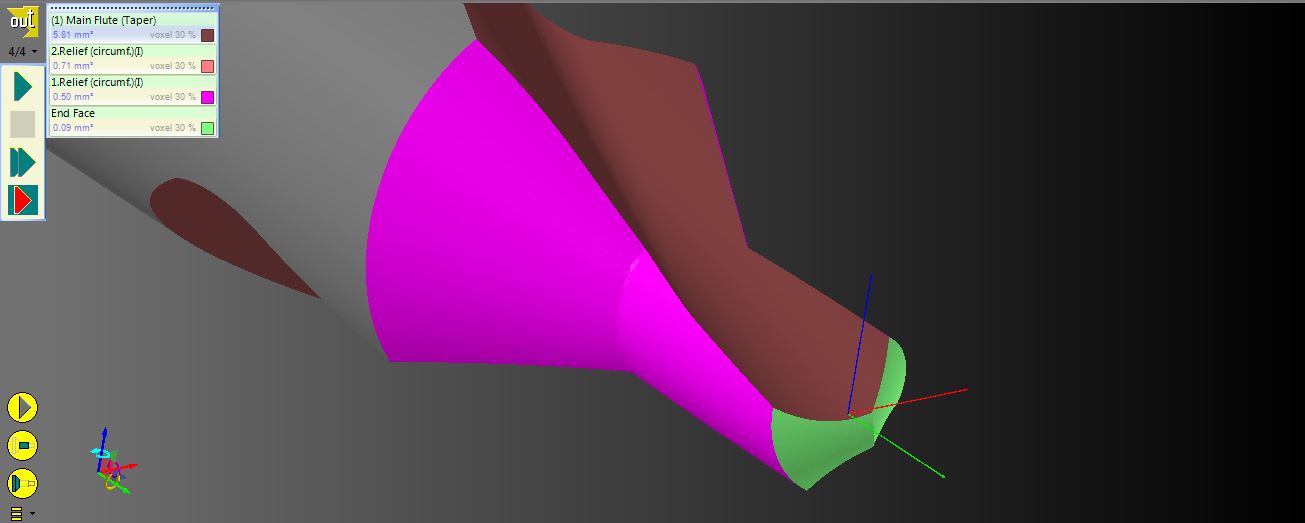

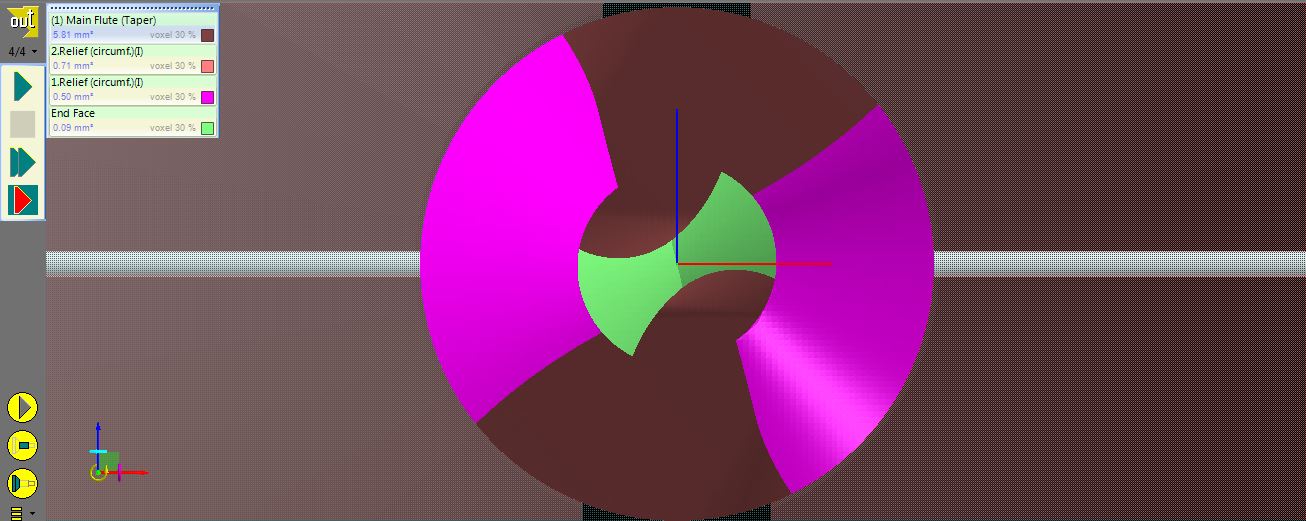

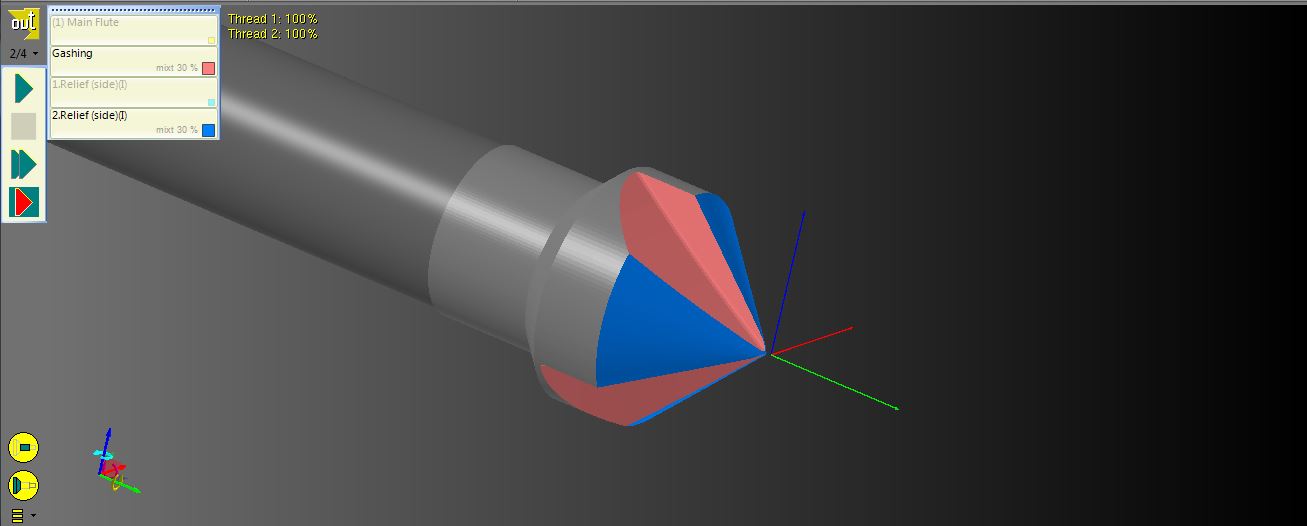

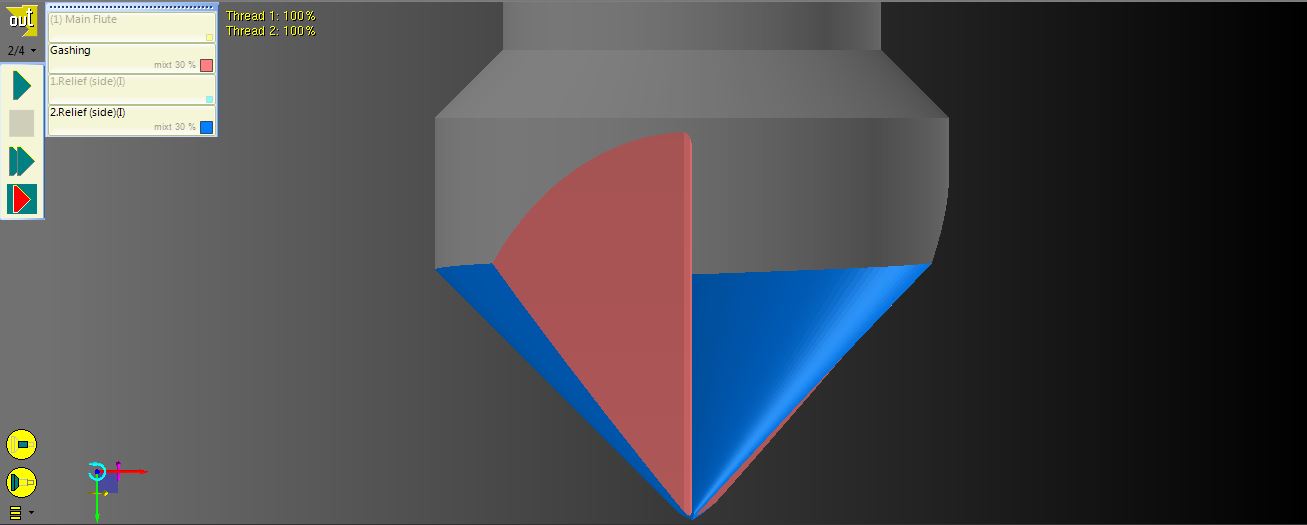

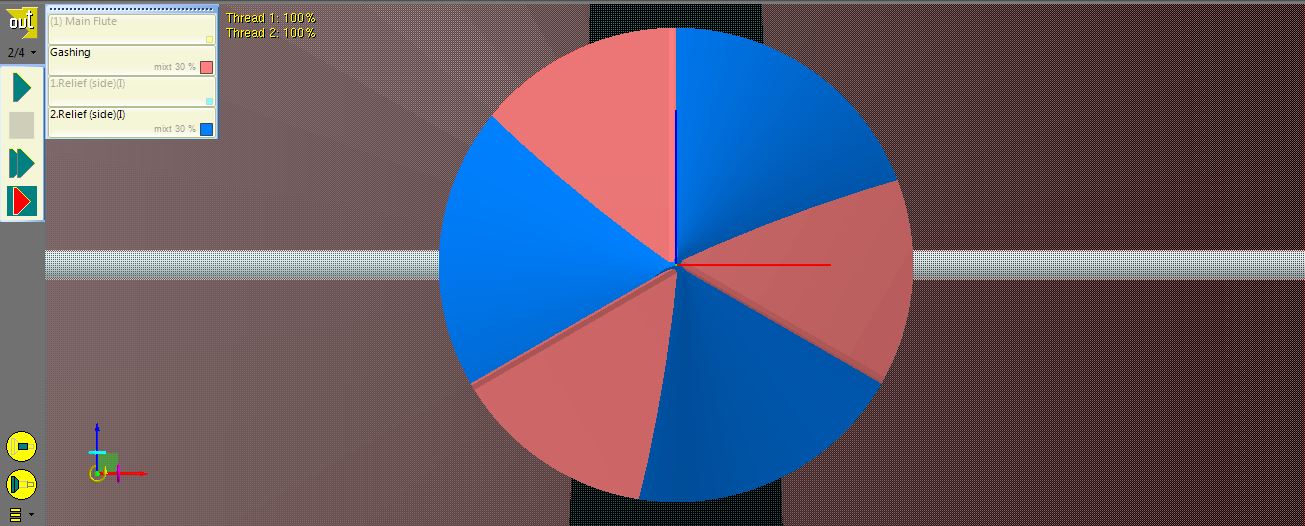

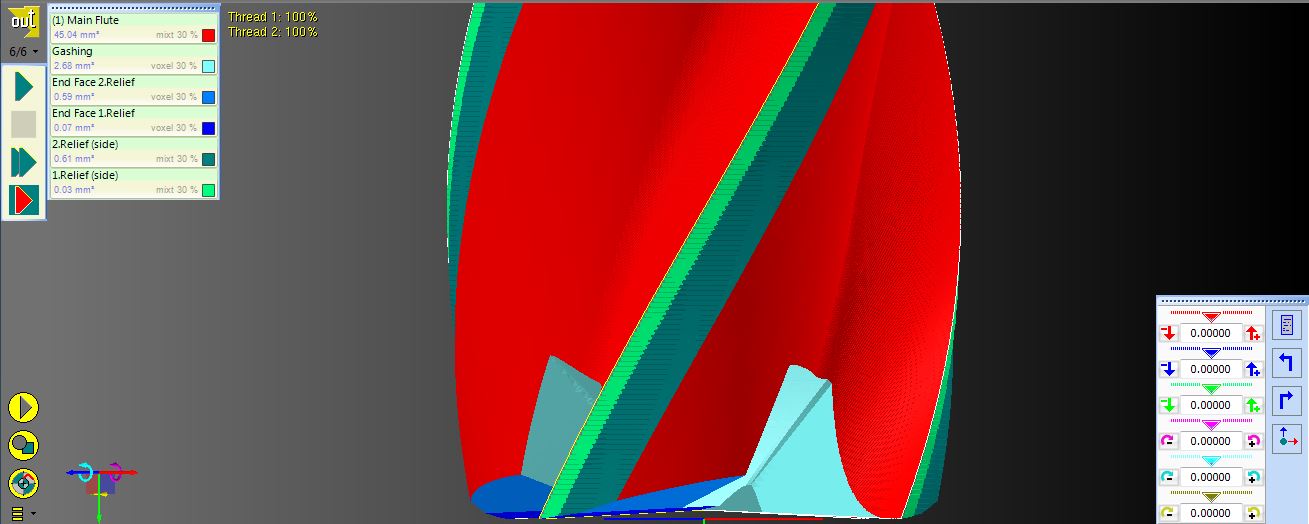

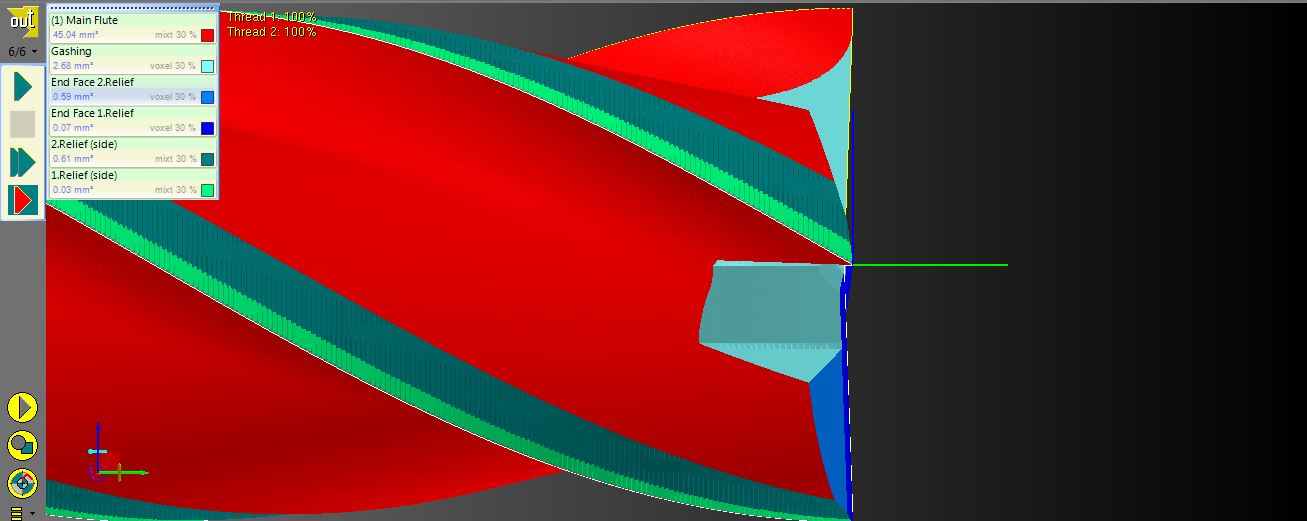

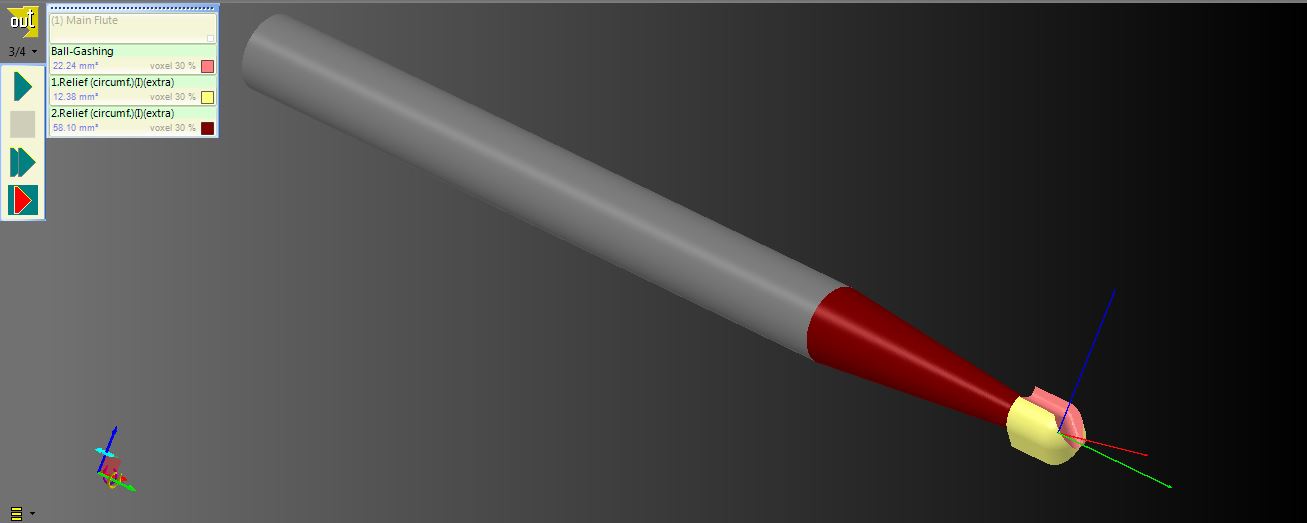

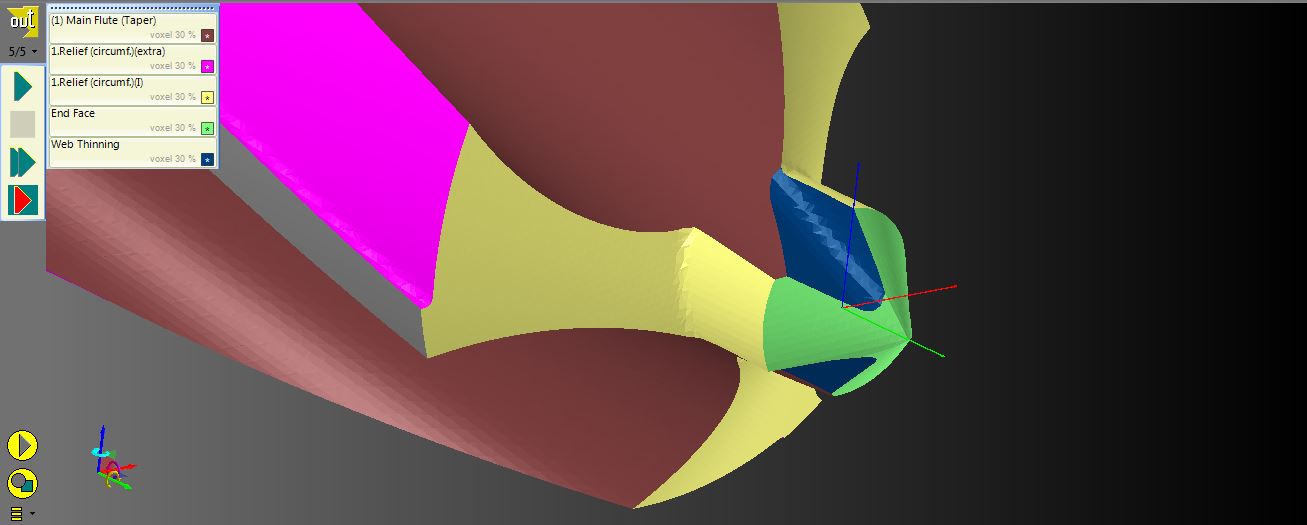

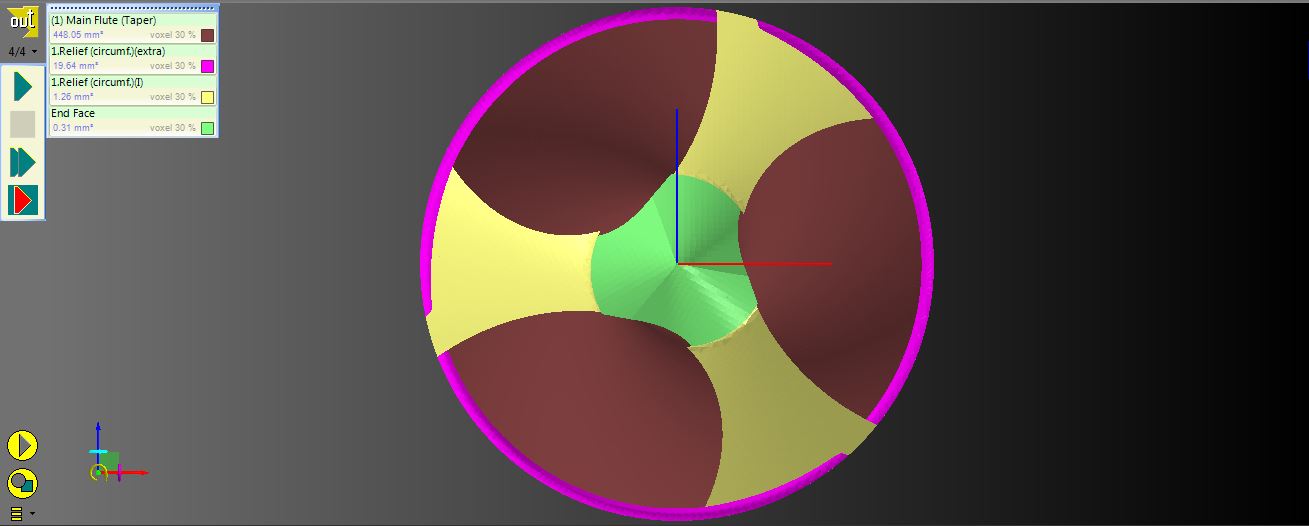

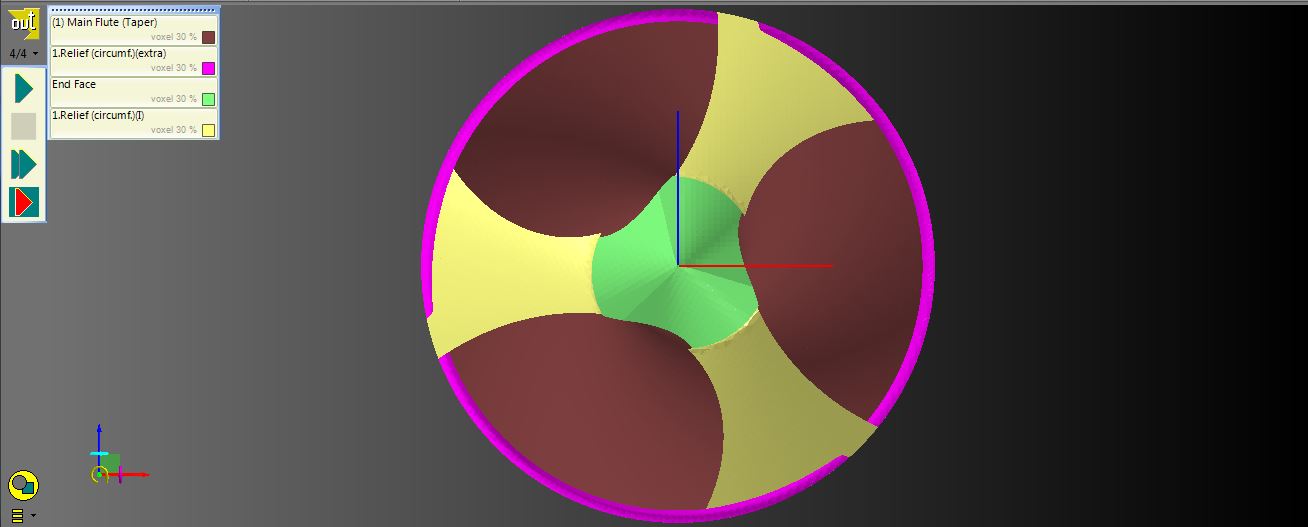

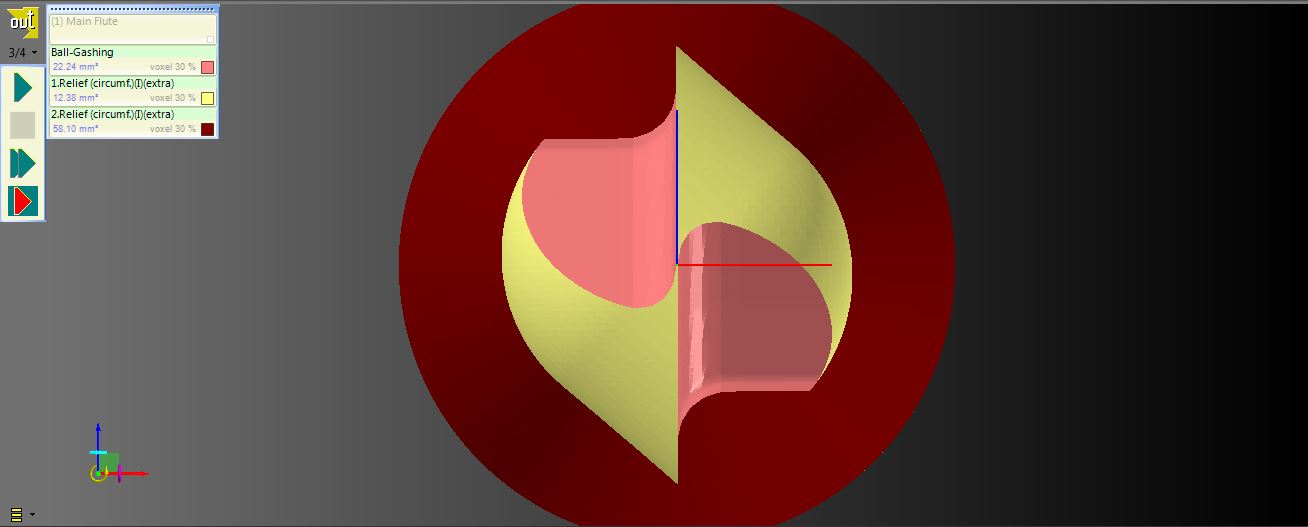

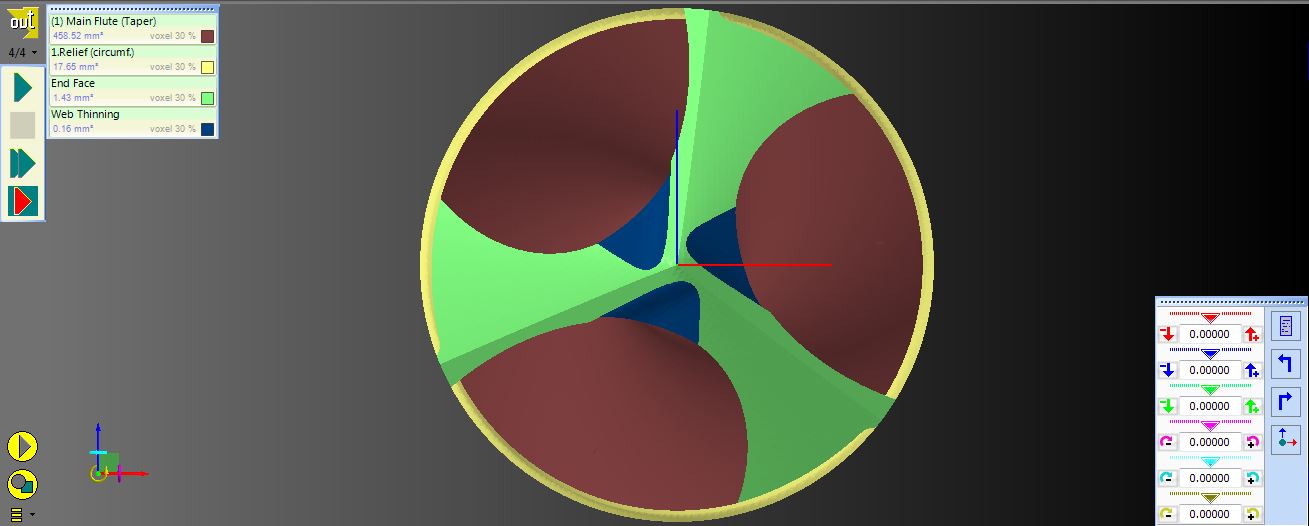

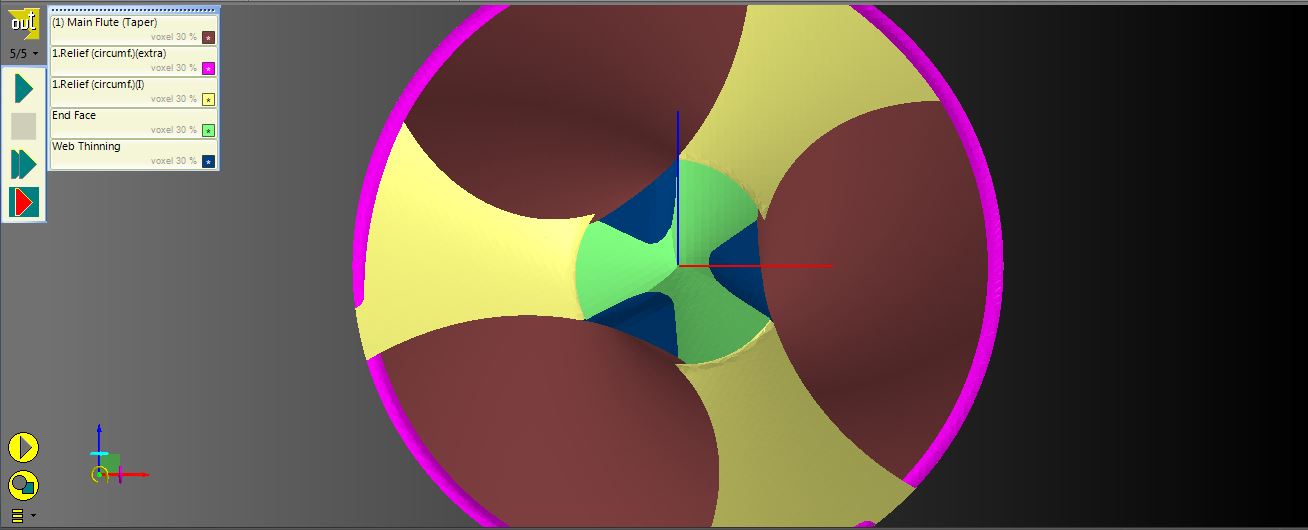

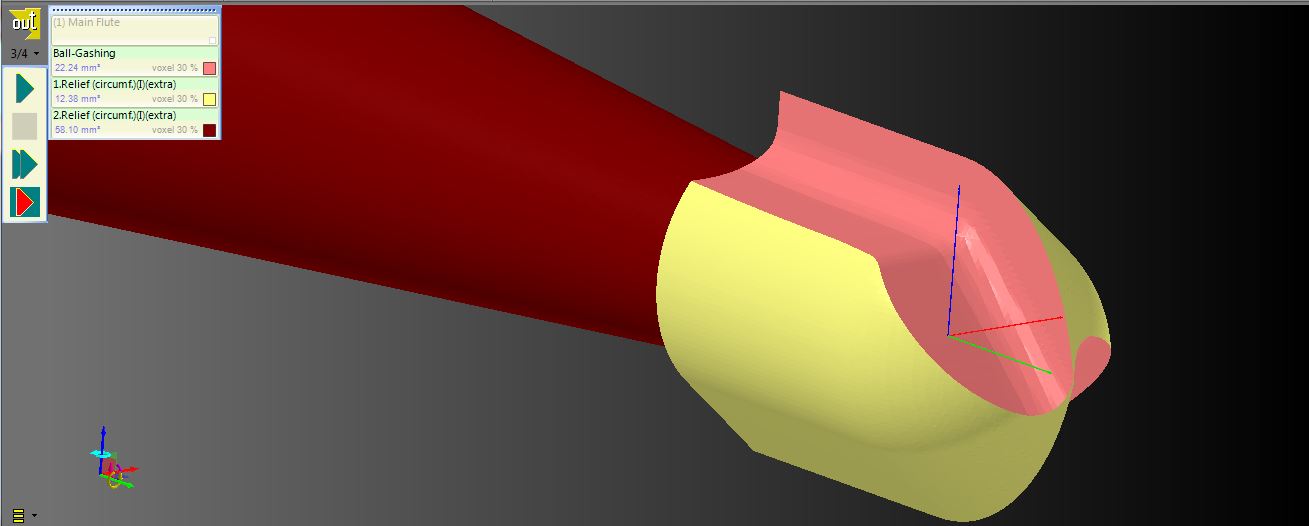

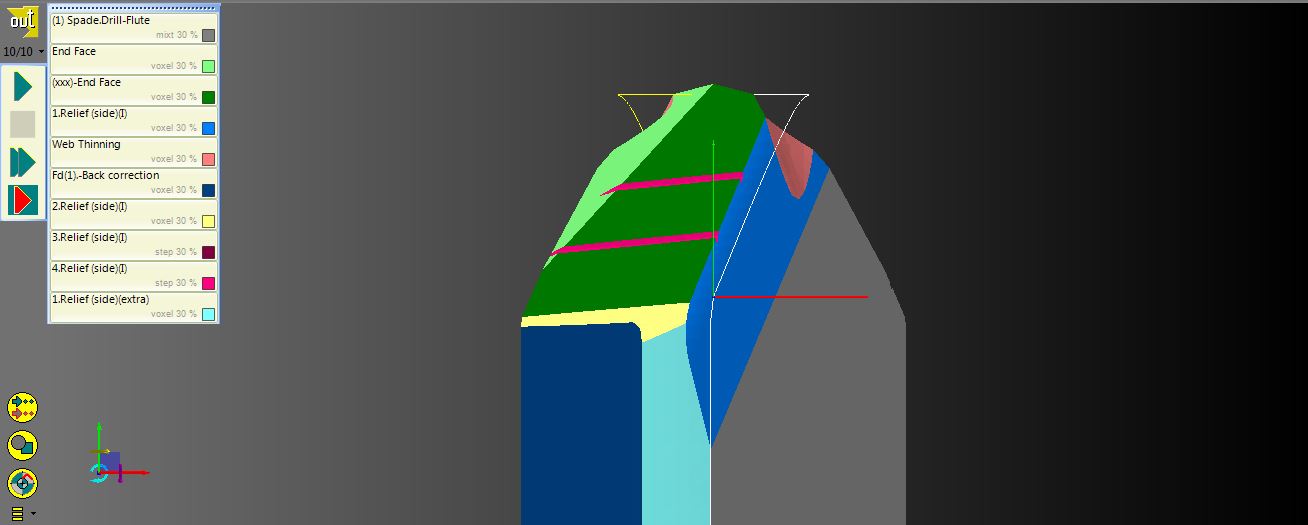

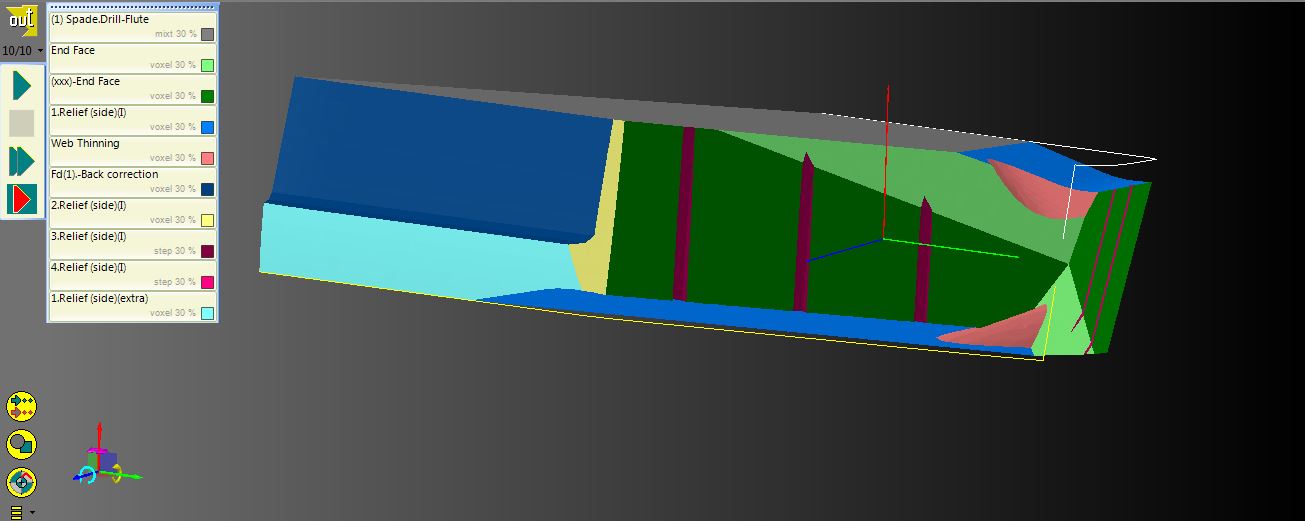

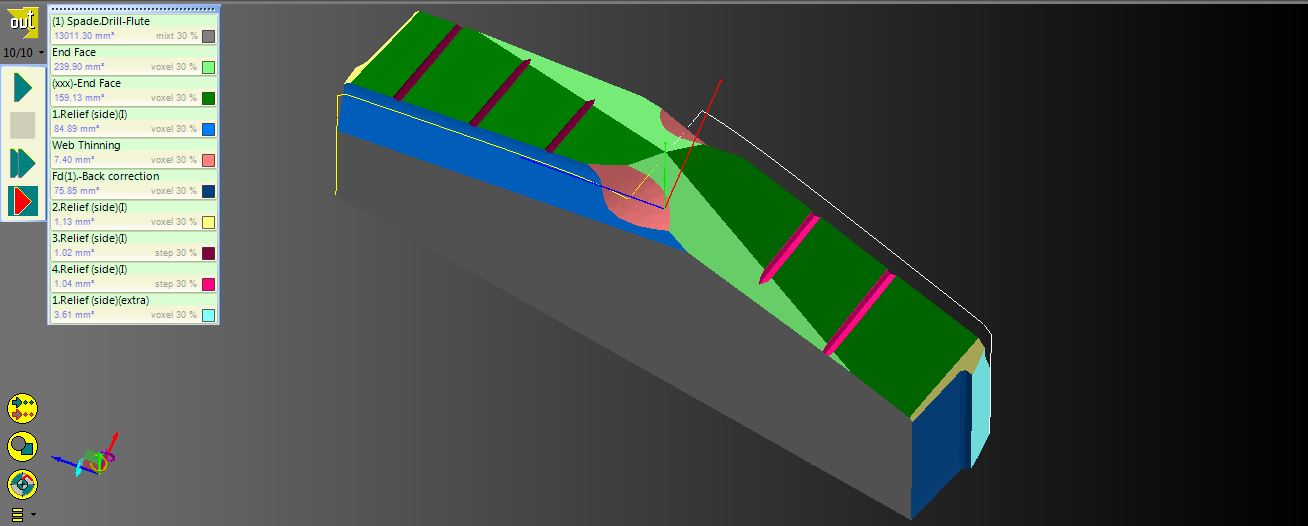

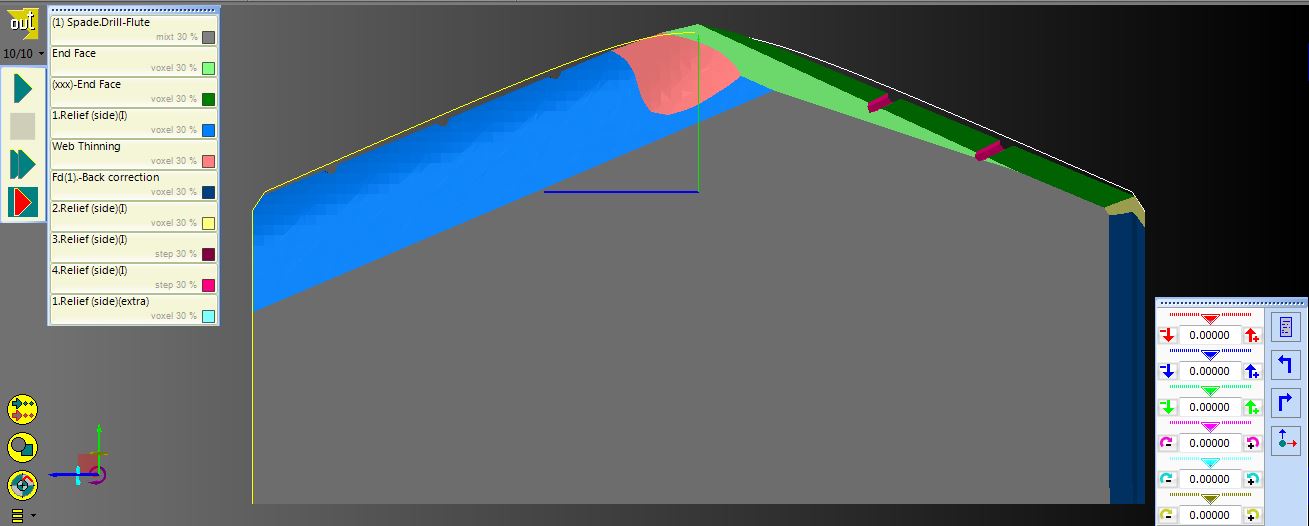

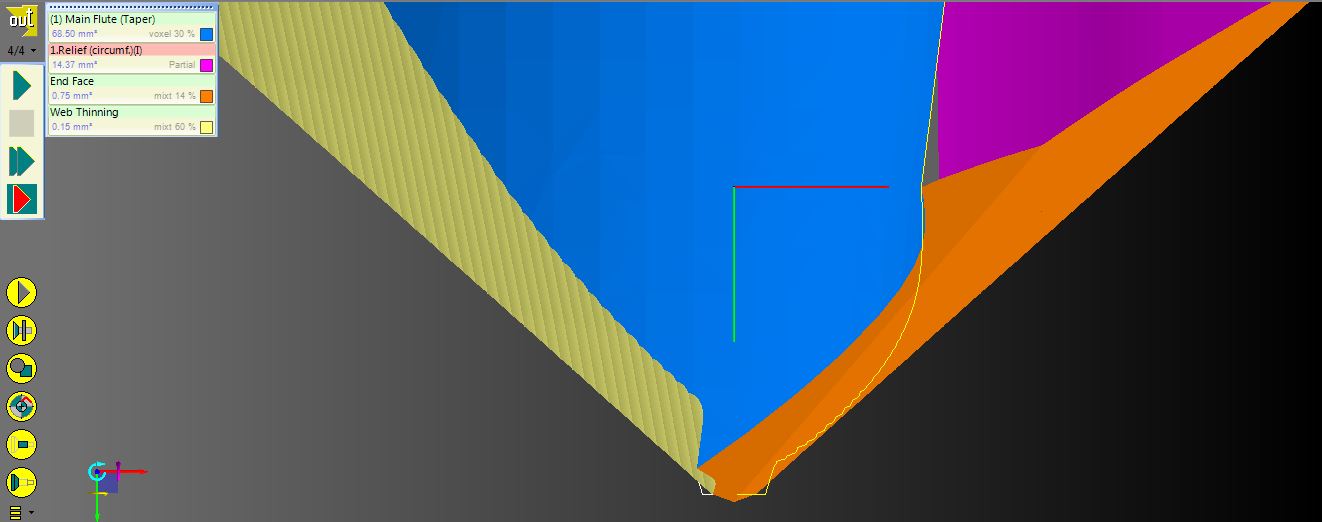

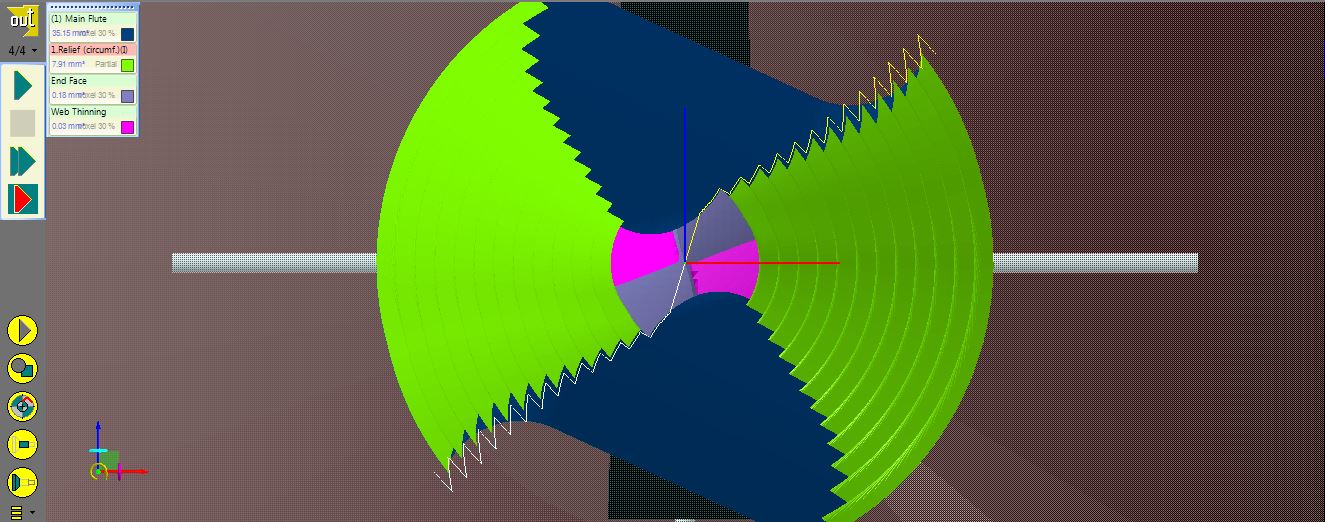

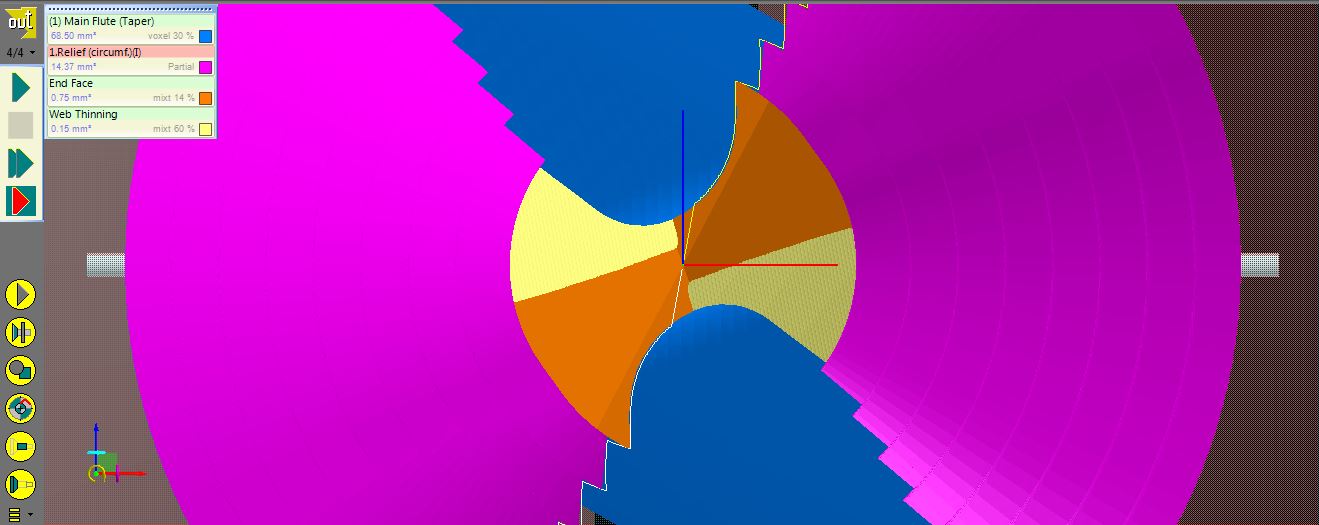

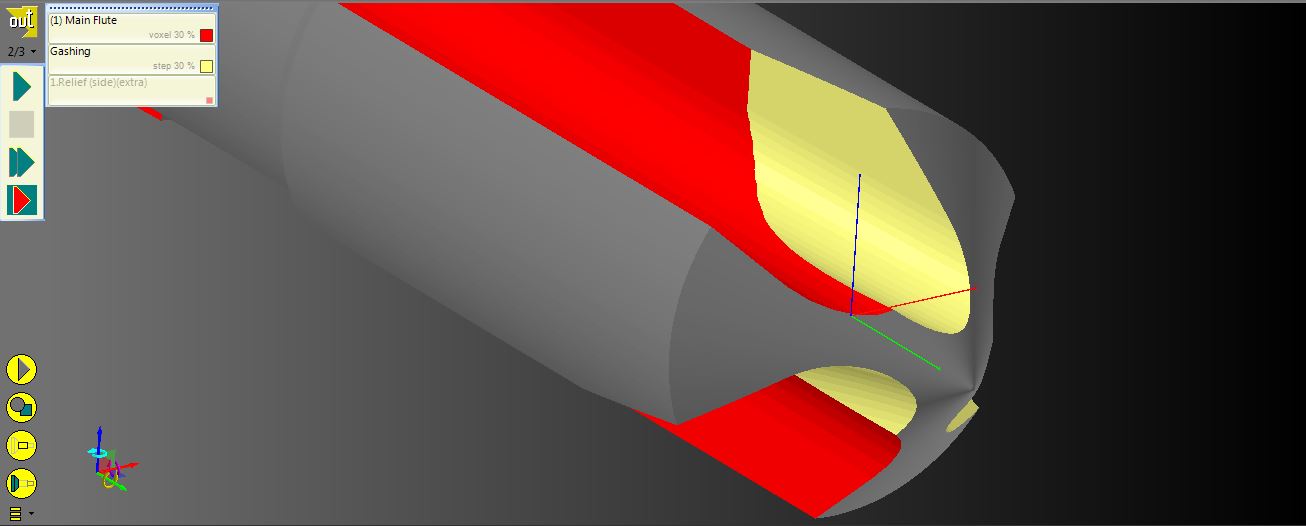

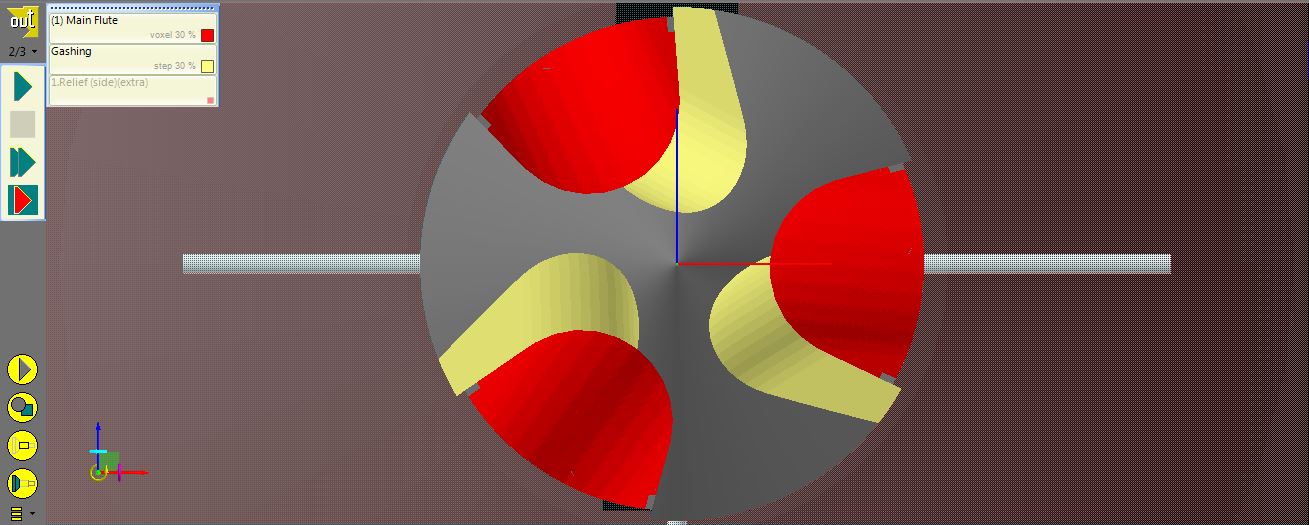

SAMPLE APPLICATIONS / GRINDING OPERATIONS

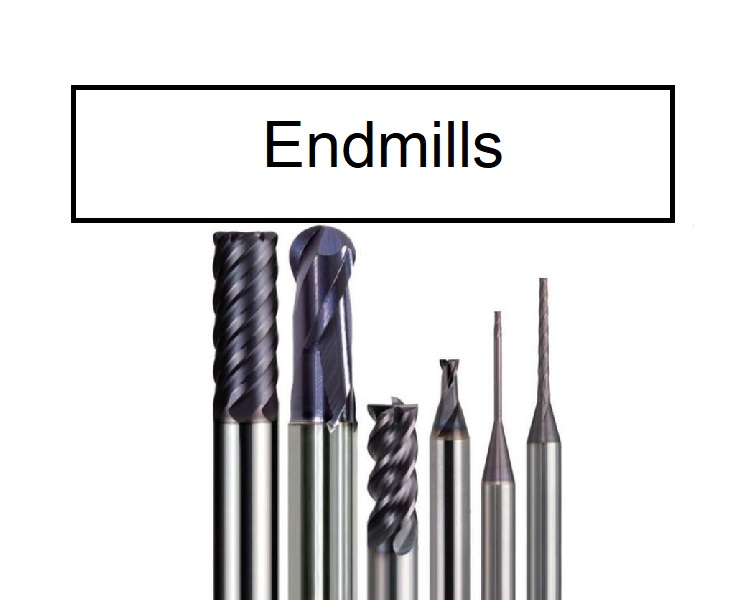

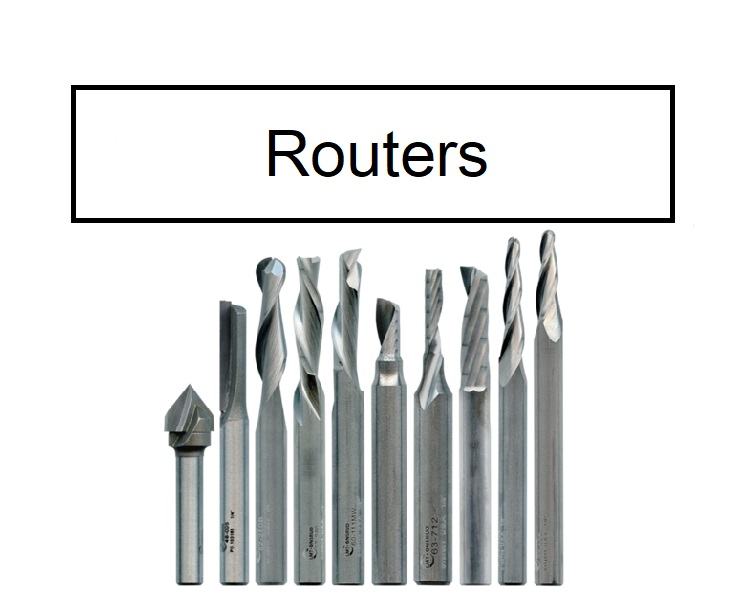

- Endmills Carbide & HSS: Shank and Cutting diameter

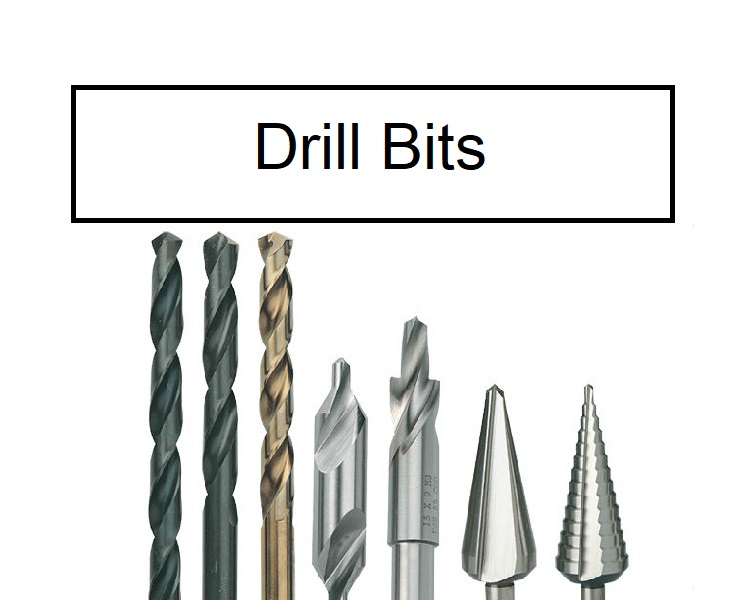

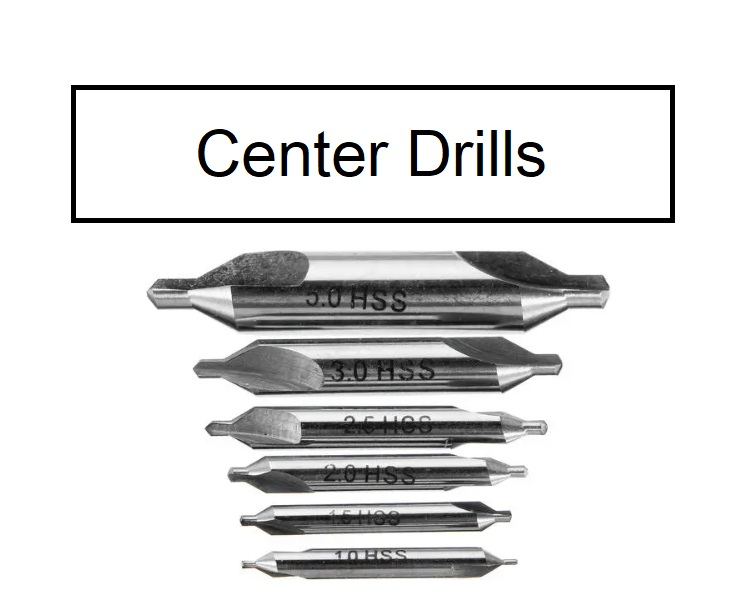

- Twist drills (Industrial/ Aircraft/ S+D/ DIY/ Medical/ PCB)

- Carbide, HSS & Stainless: Shank & Cutting diameter

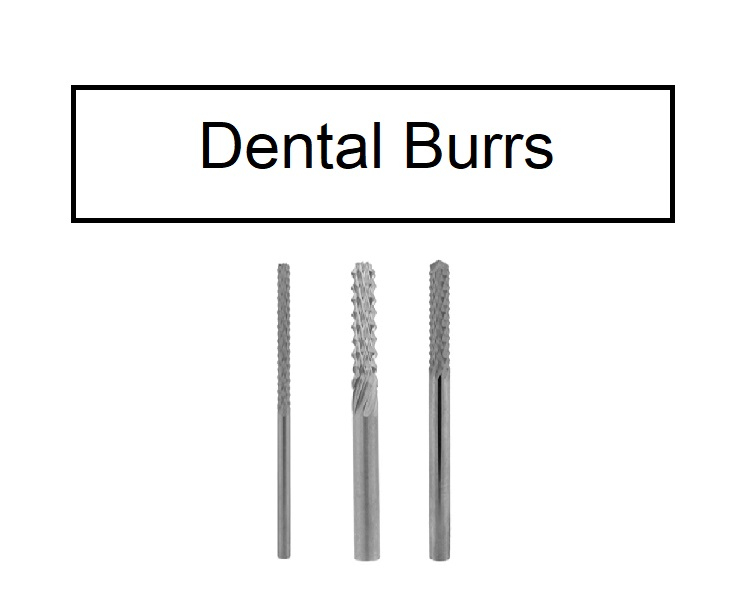

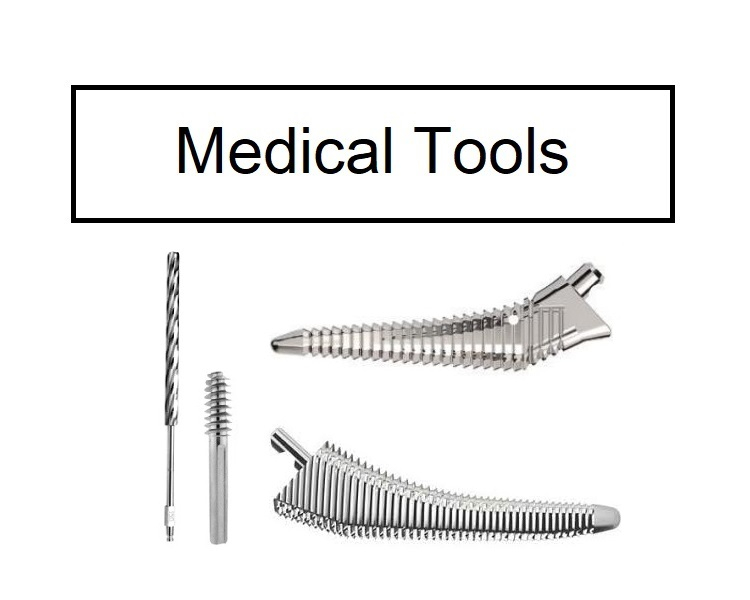

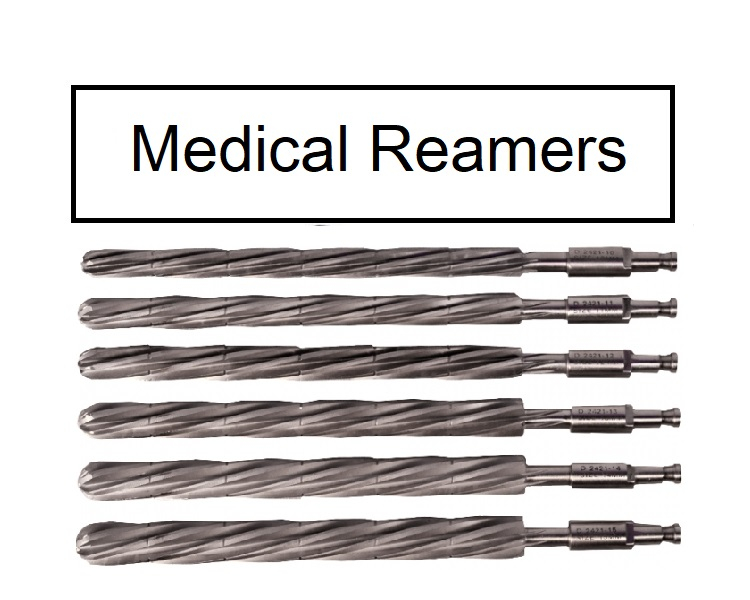

- Medical Tools Stainless & Titanium: Drills, Reamers

- Reamers Carbide & HSS: Shank

- Countersinks Carbide & HSS: Shank & OD

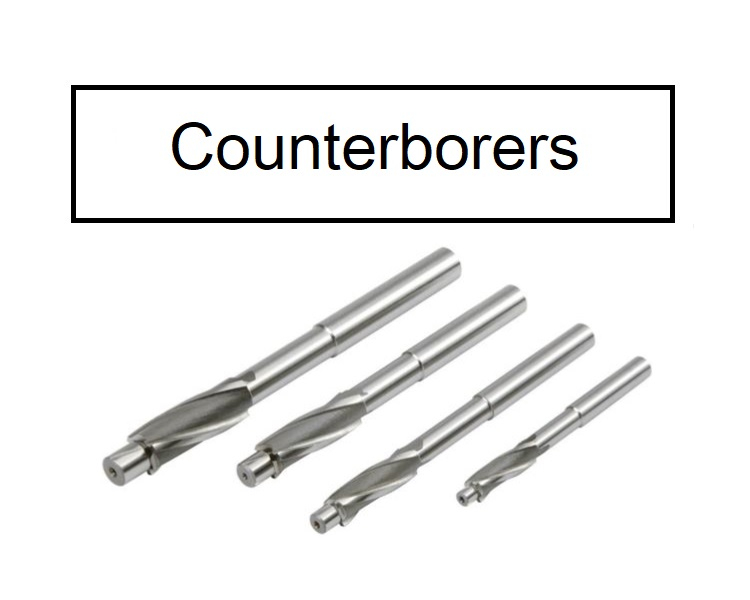

- Counterborers: Complete tool profile

- Taps Carbide & HSS: Complete tool profile and square

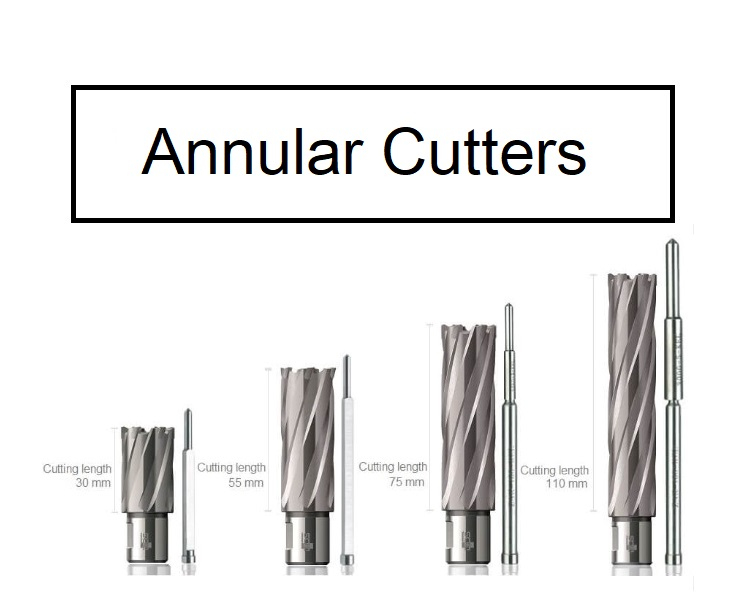

- Annular Hole Cutters: Shank & OD

- Any straight OD’s, squares, chamfers, contours, tapers, shoulders, grooves, flats, threads