MODEL: UFG – UNIVERSAL FLUTE AND GUNNOSE GRINDER

FLUTE SERIES

ITM holds over 30 patented machine designs

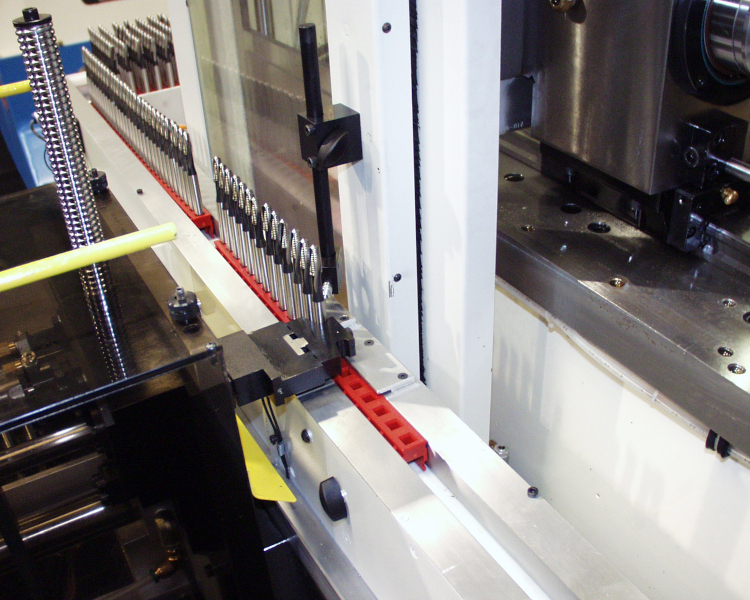

HIGH PRODUCTIVITY FLUTE GRINDING

PRECISION FLUTE GRINDING

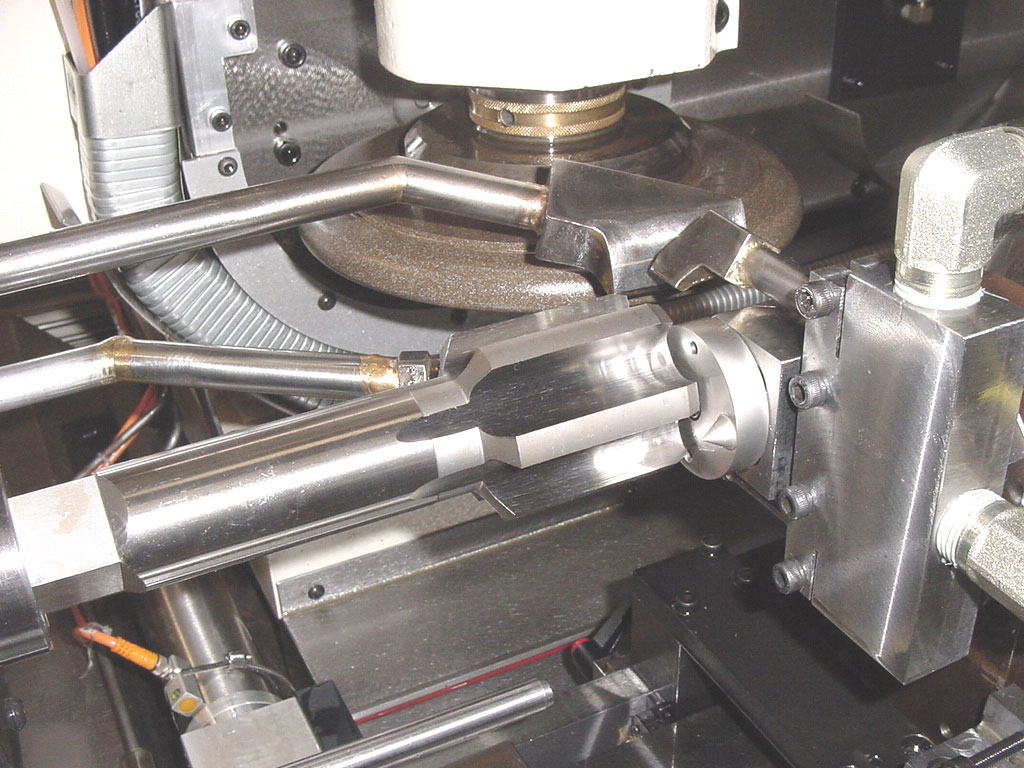

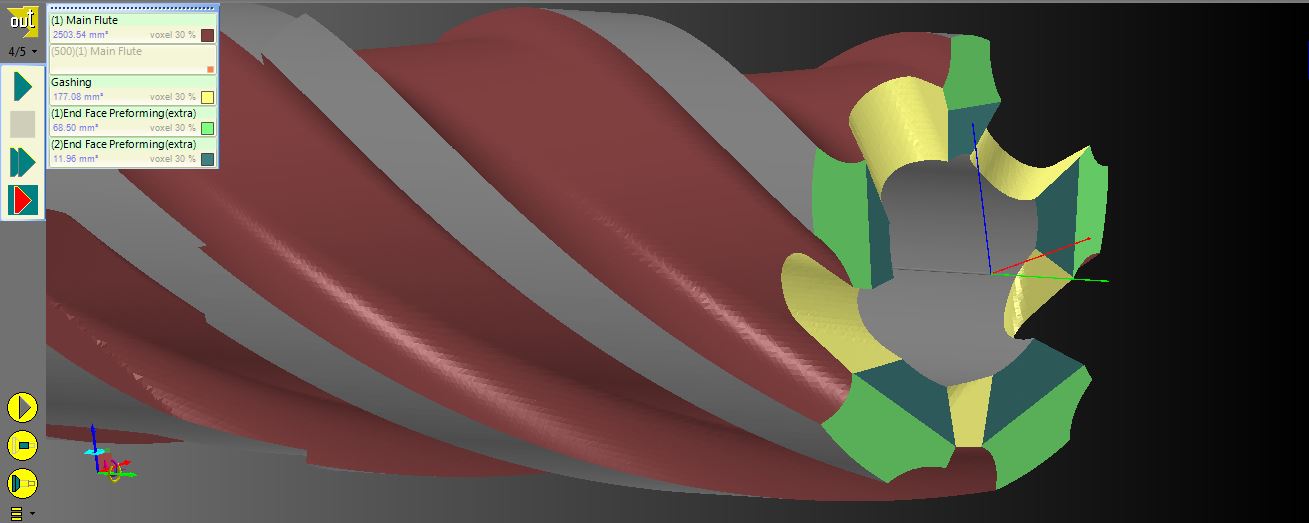

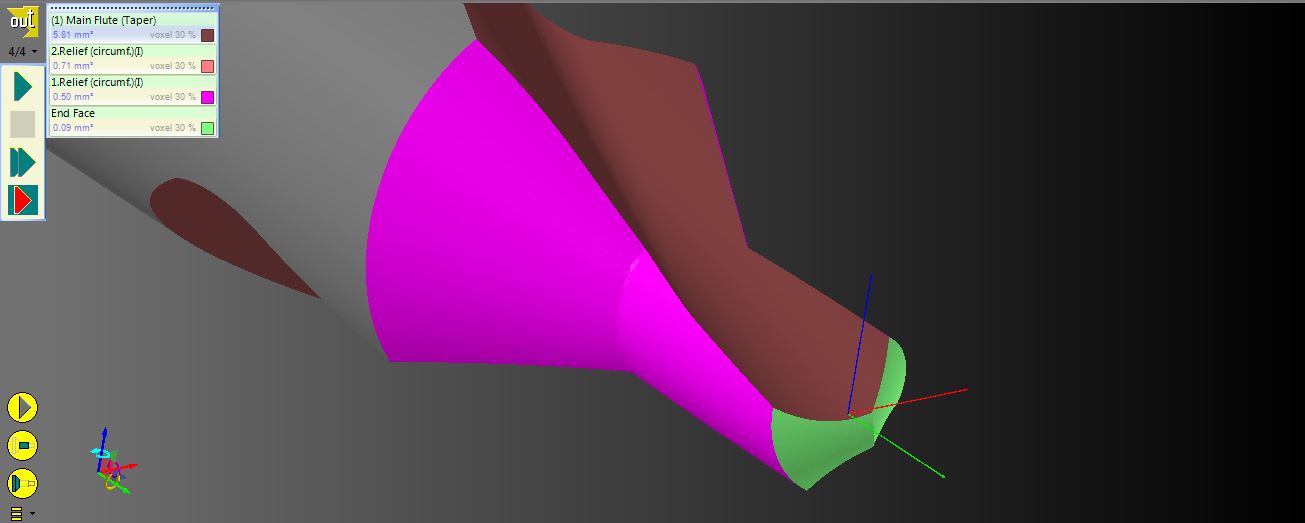

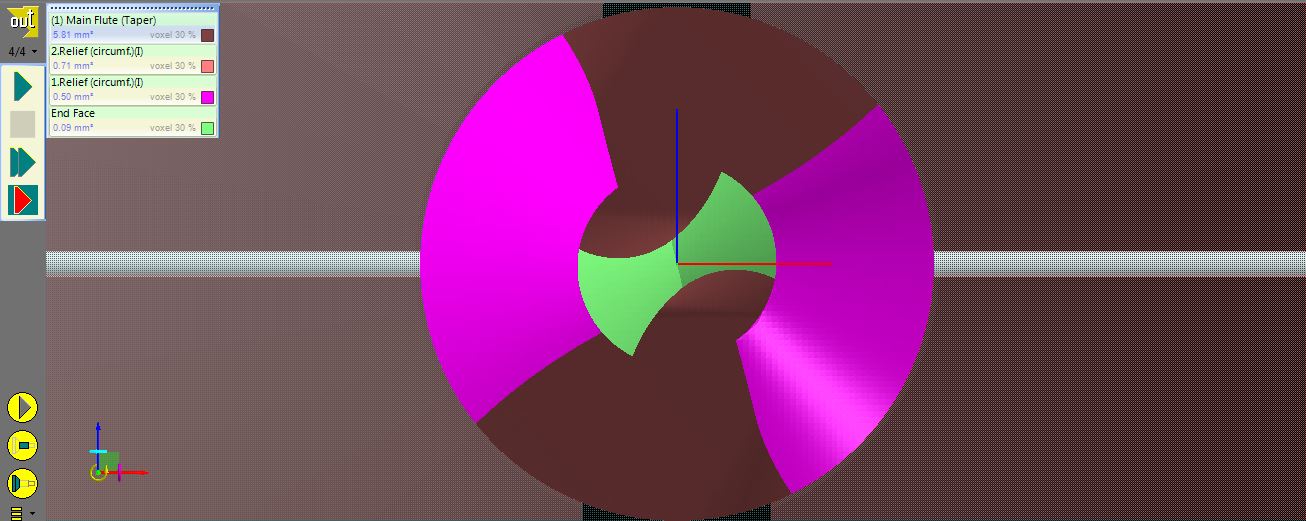

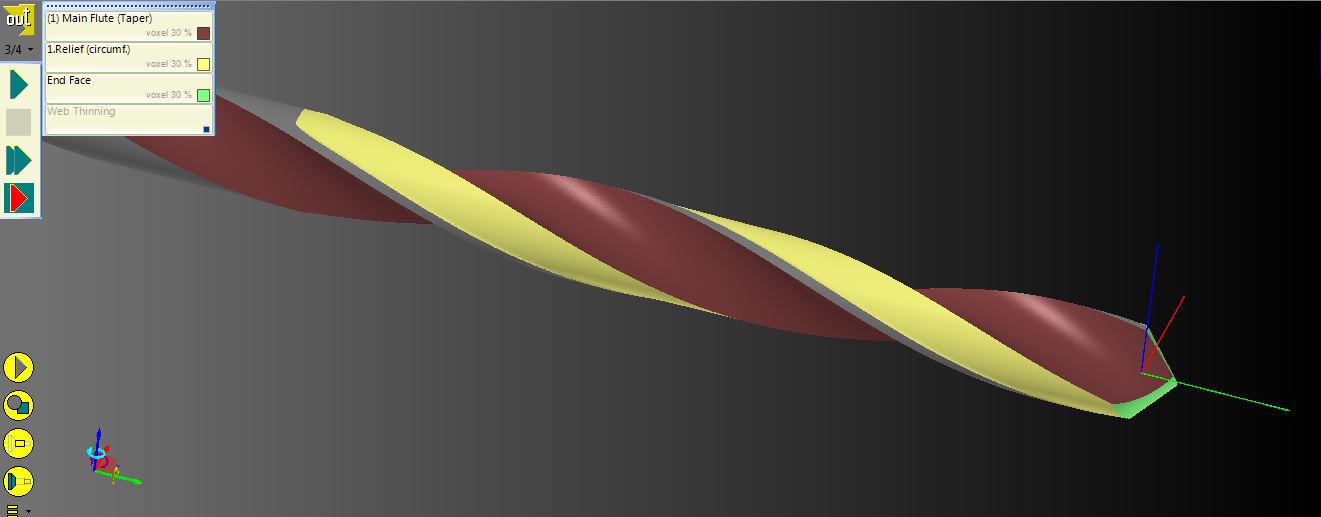

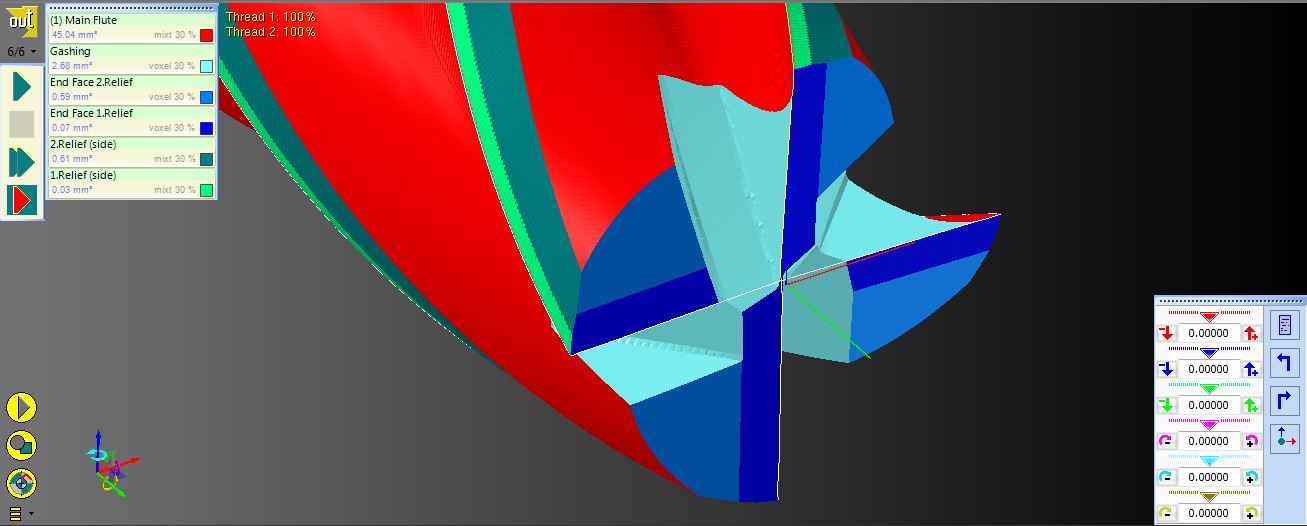

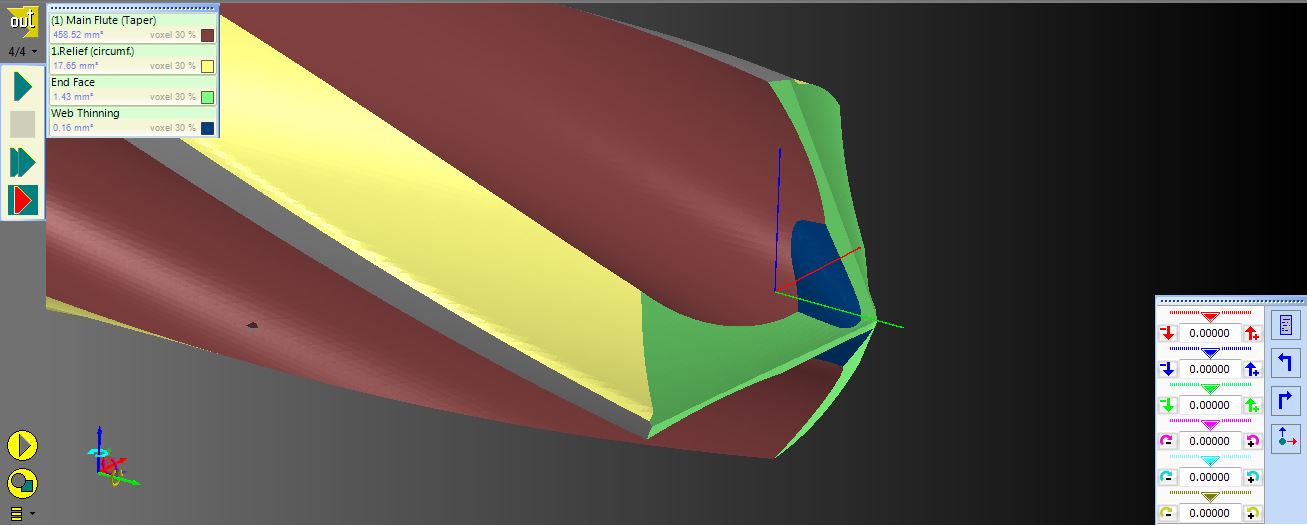

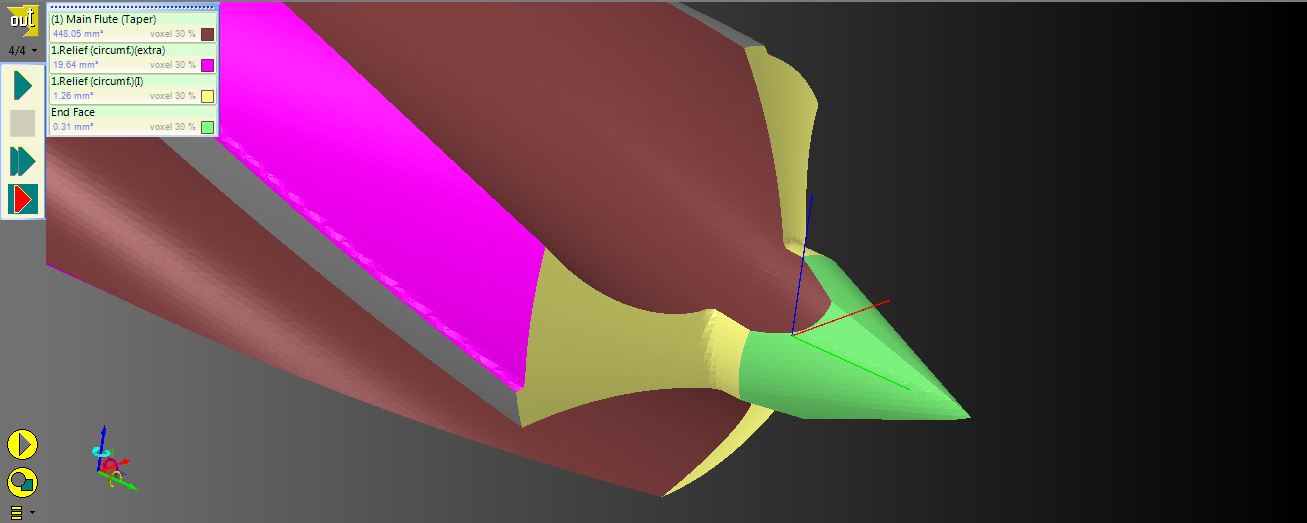

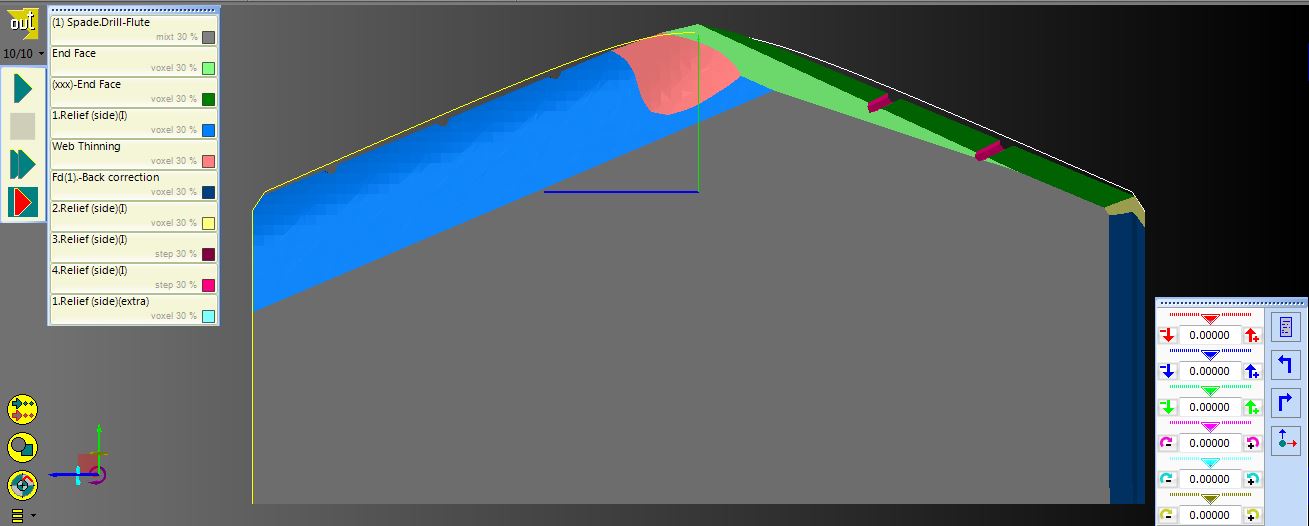

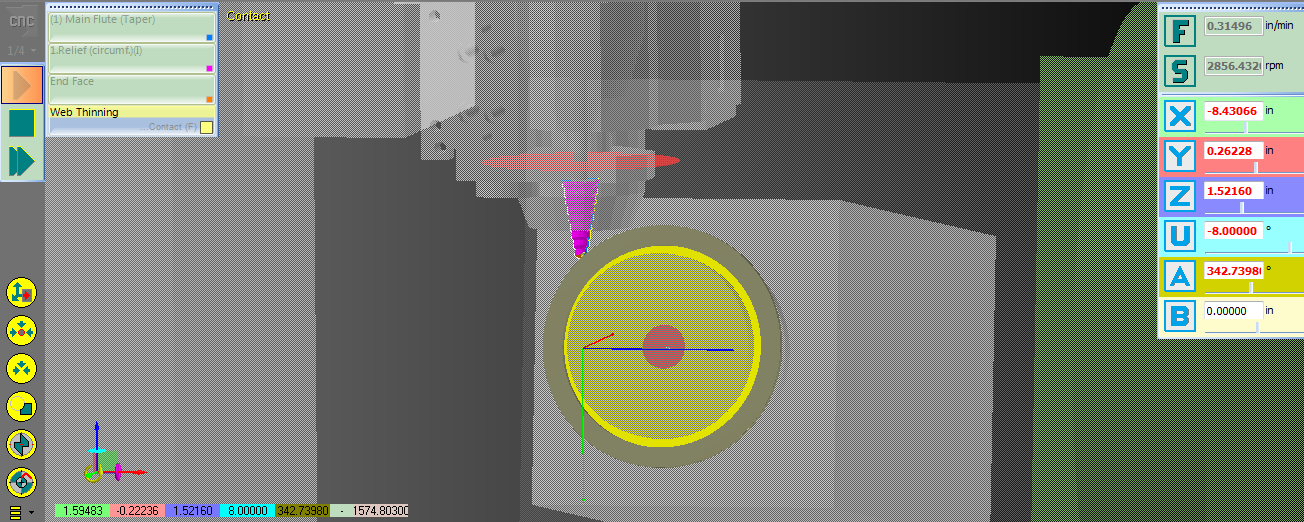

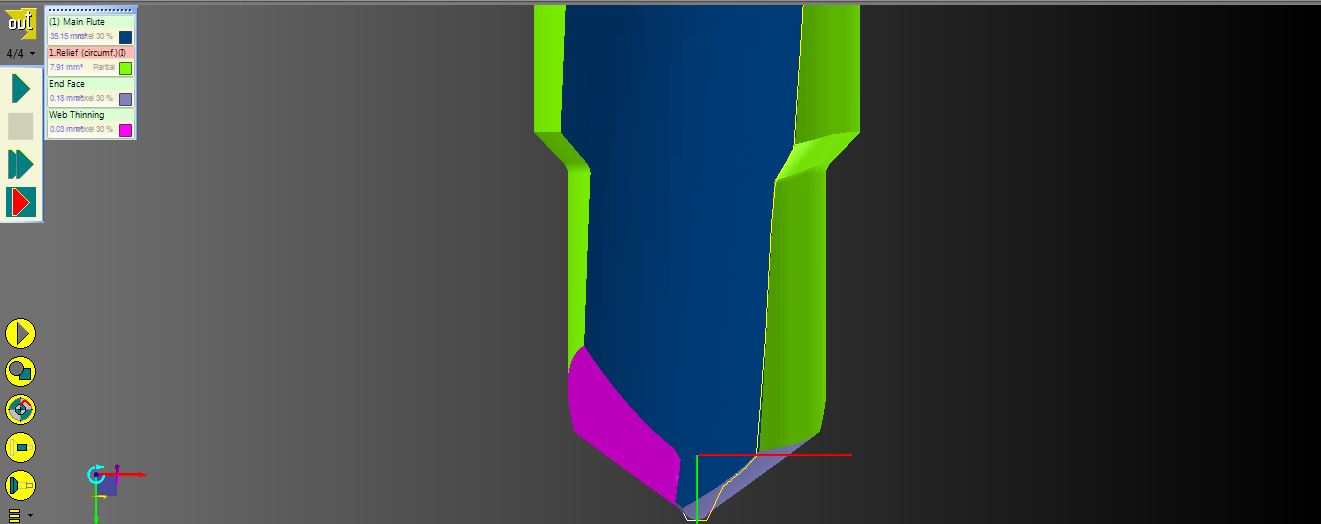

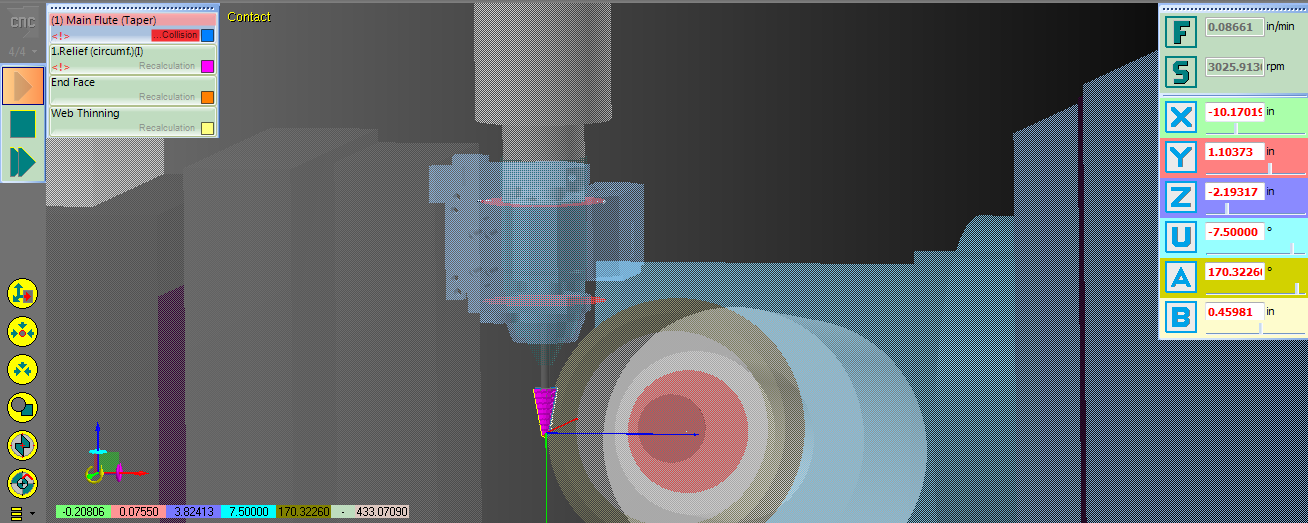

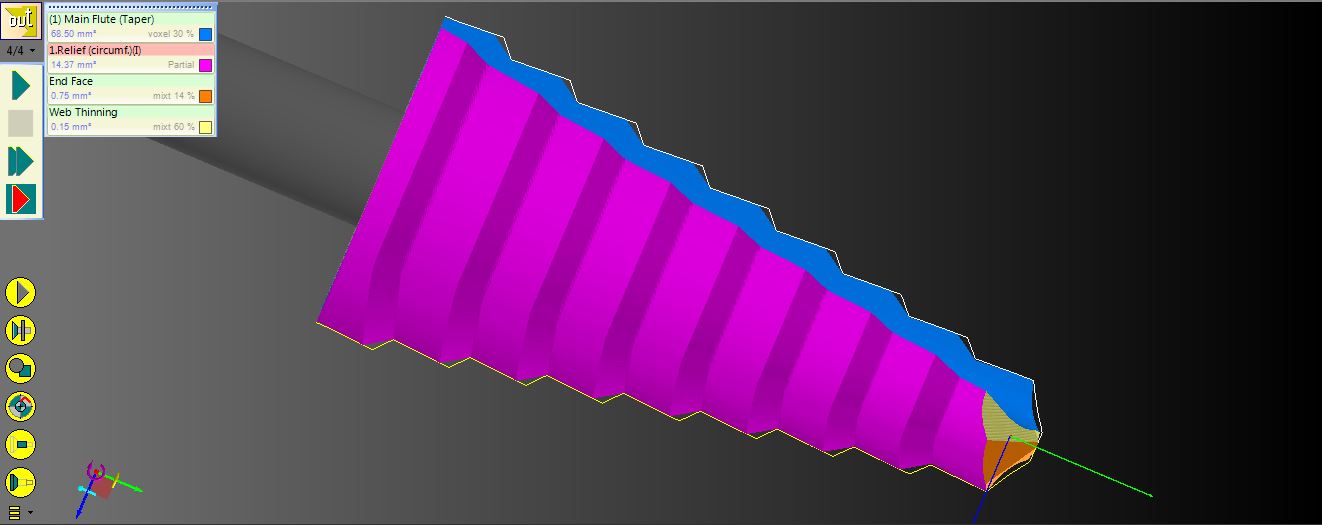

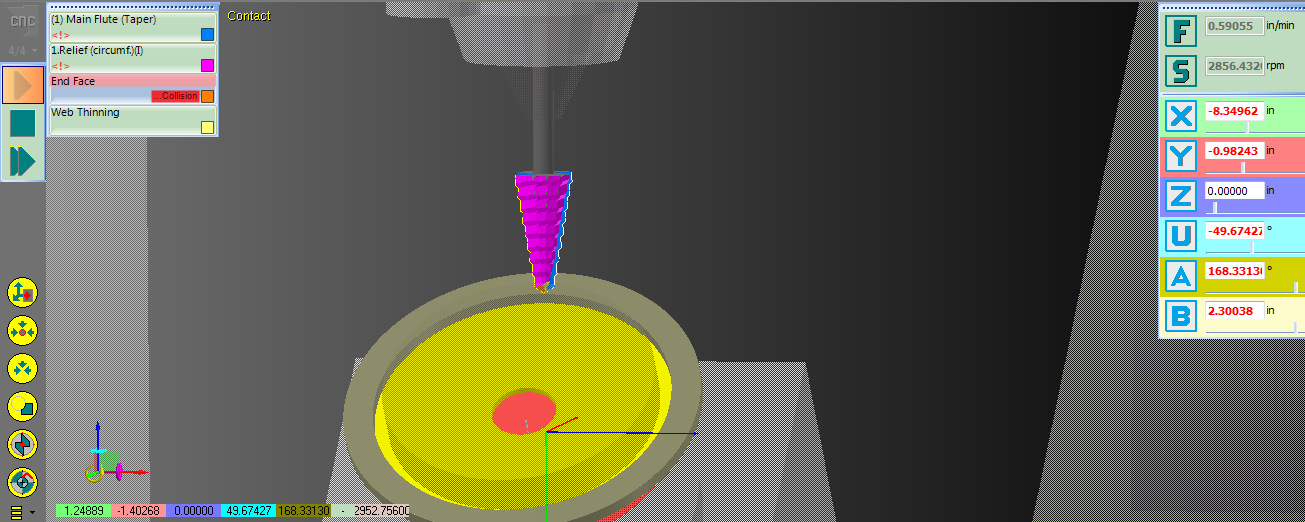

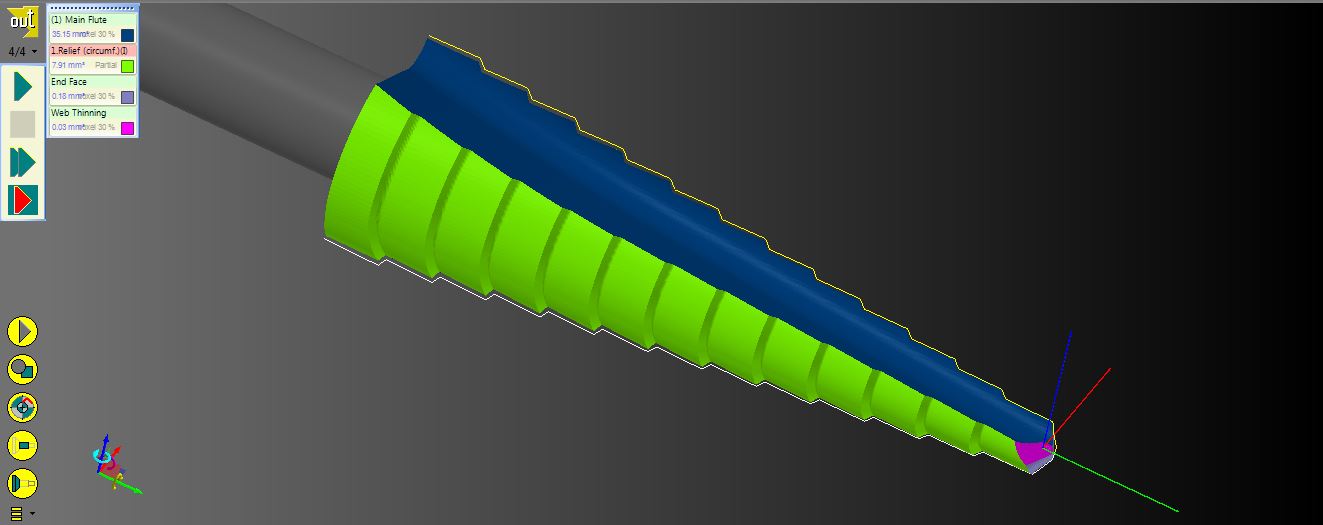

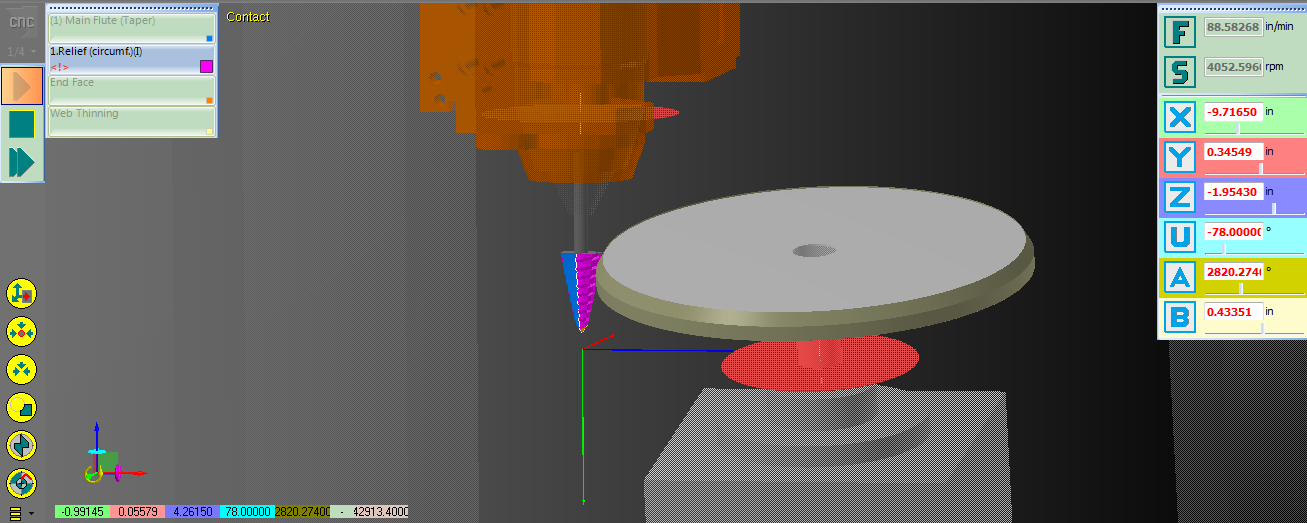

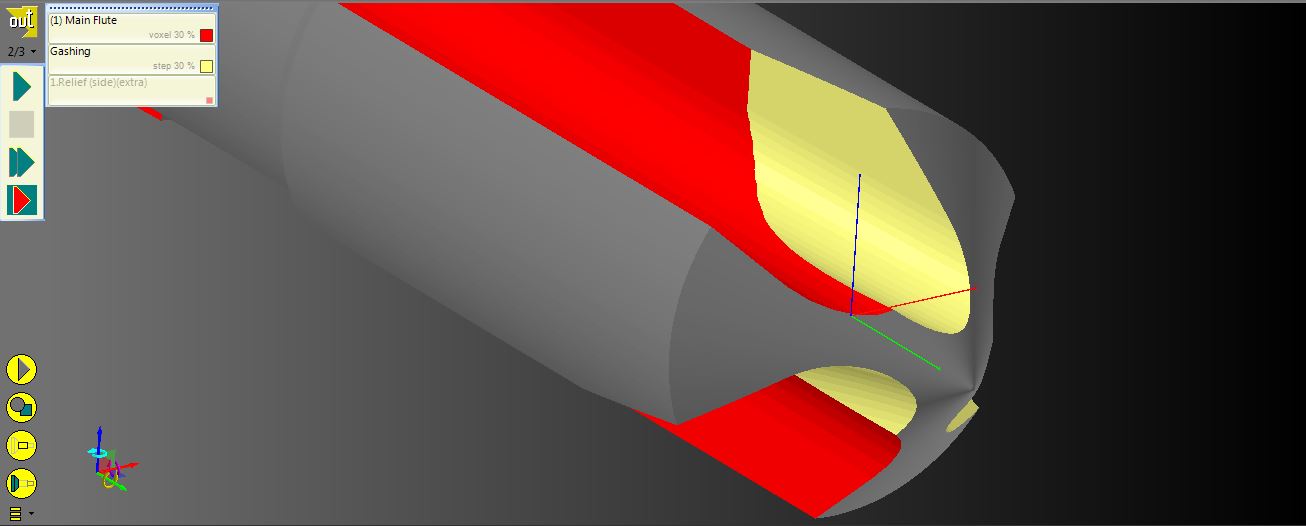

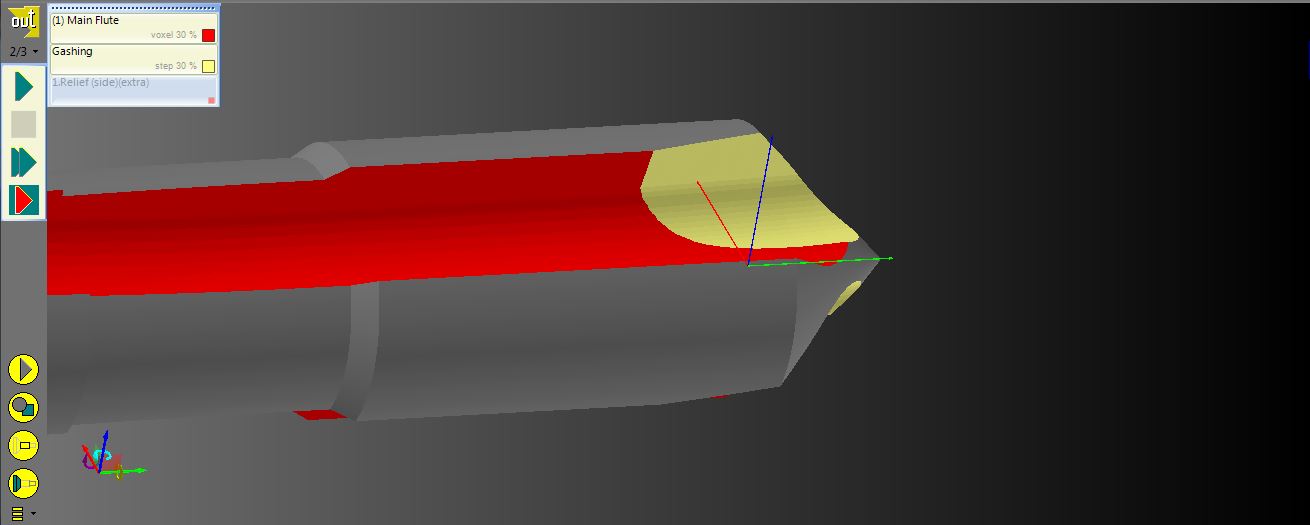

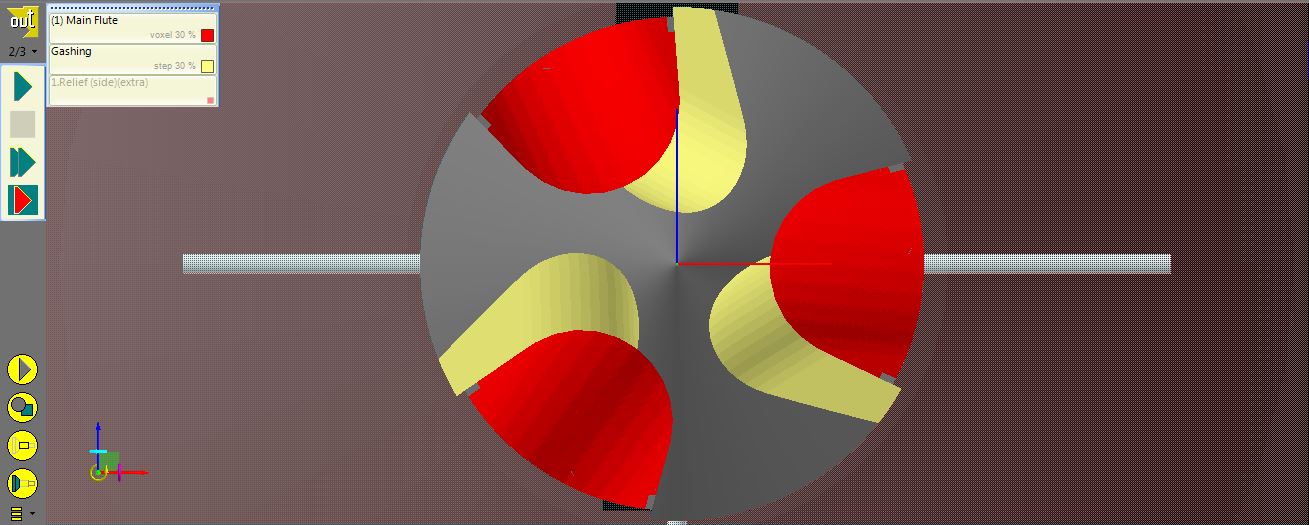

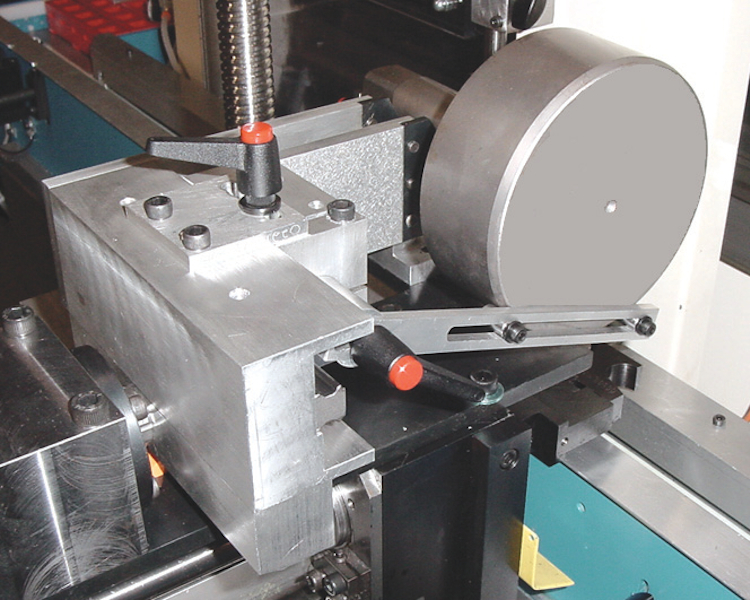

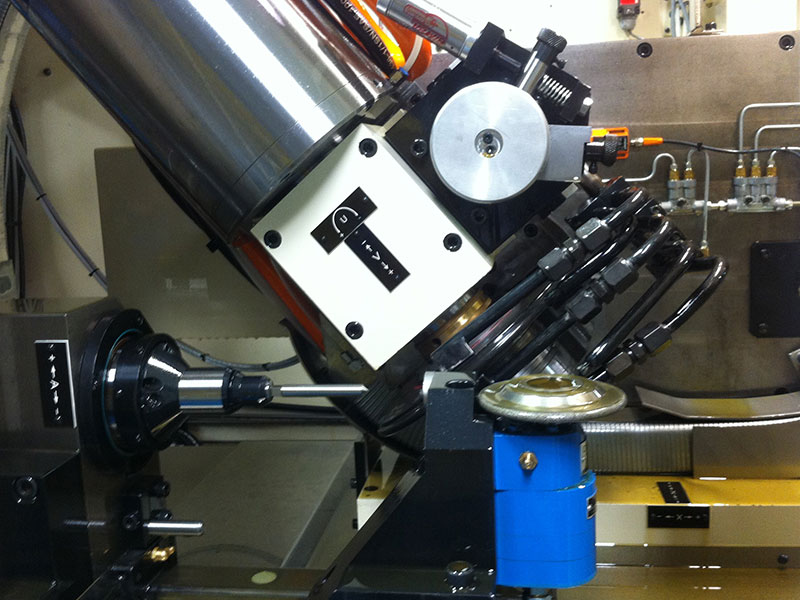

Flute grinding is the most time consuming, cost intensive manufacturing step during tool grinding. ITM’s response is the UFG, a high power high productivity flute grinding machine with a heavy welded and stress-relieved base. The workhead is mounted on a heavy precision slide which is moved by a variable speed position hydraulic cylinder for loading and unloading tools. A collet assembly or square driver assembly are available.

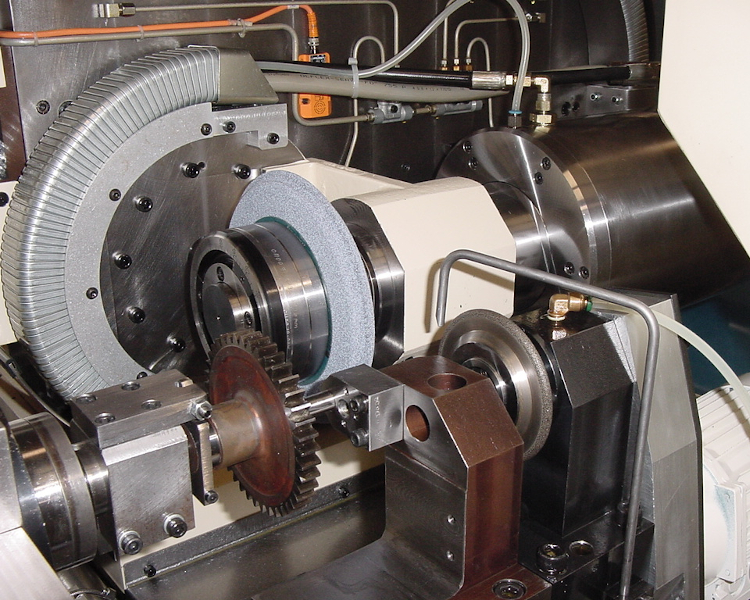

The UFG can be operated with wheel speeds up to 262ft/s when using the correct grinding wheels. The rigidity of the machine, as well as the programmable capability, allows the use of standard resinoid wheels, plated CBN wheels, dress-able CBN wheels or diamond wheels. This design offers the rigidity needed for high production applications. All axes are controlled by digital AC servo motors with encoder feedback. The X and Z axes have an incremental movement of 0.00004” with a rapid traverse rate up to 98.4in/min. The resolution of the A and U axes is 0.001°.

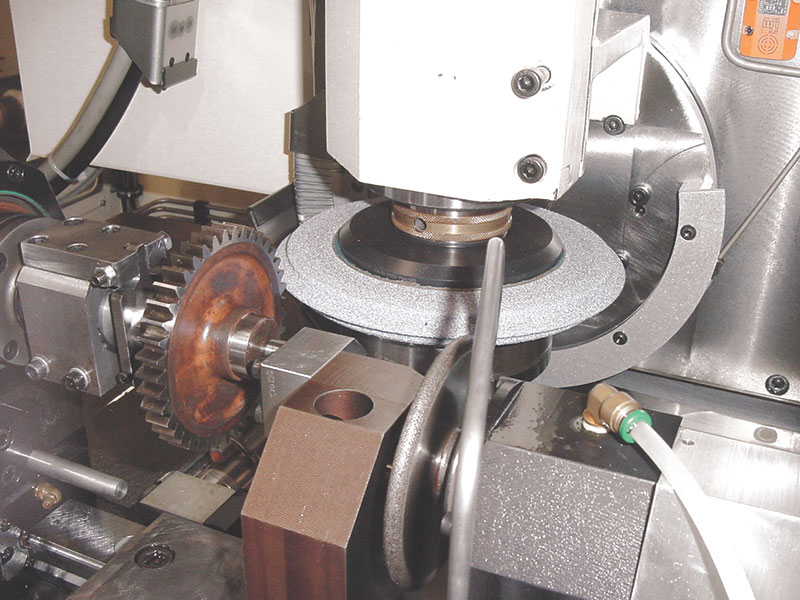

Gear grinding with UFG-25, up to 8″ OD

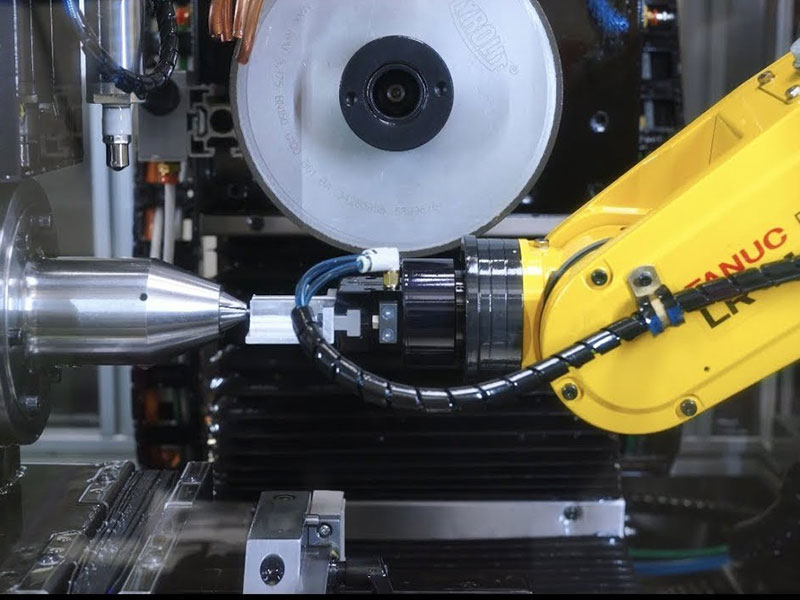

Fanuc robot loader with 5 seconds part change

How It Works

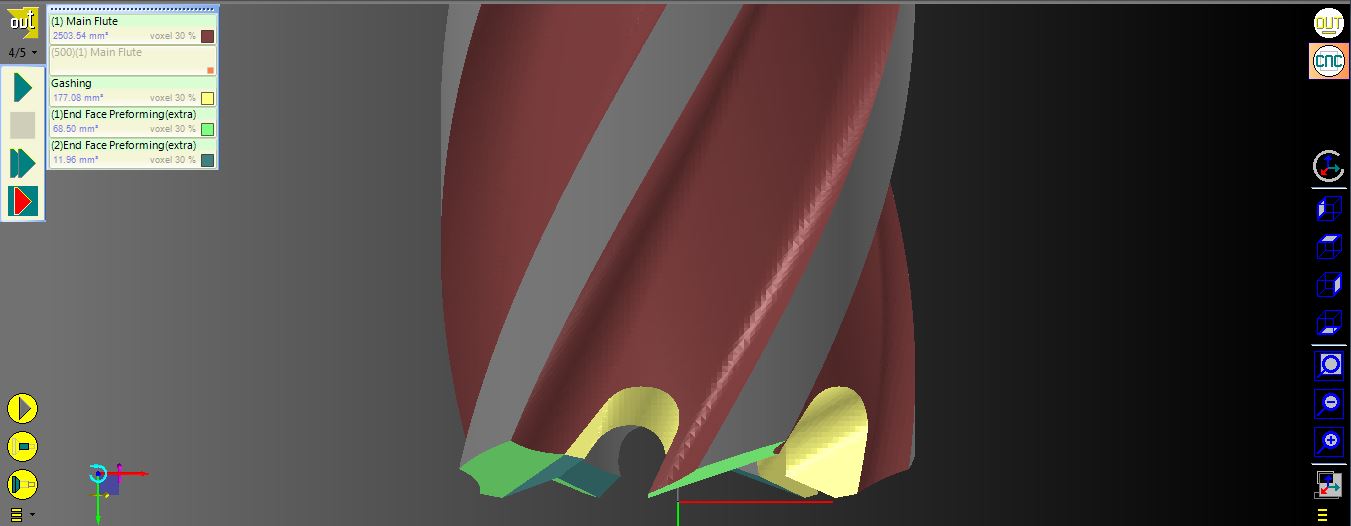

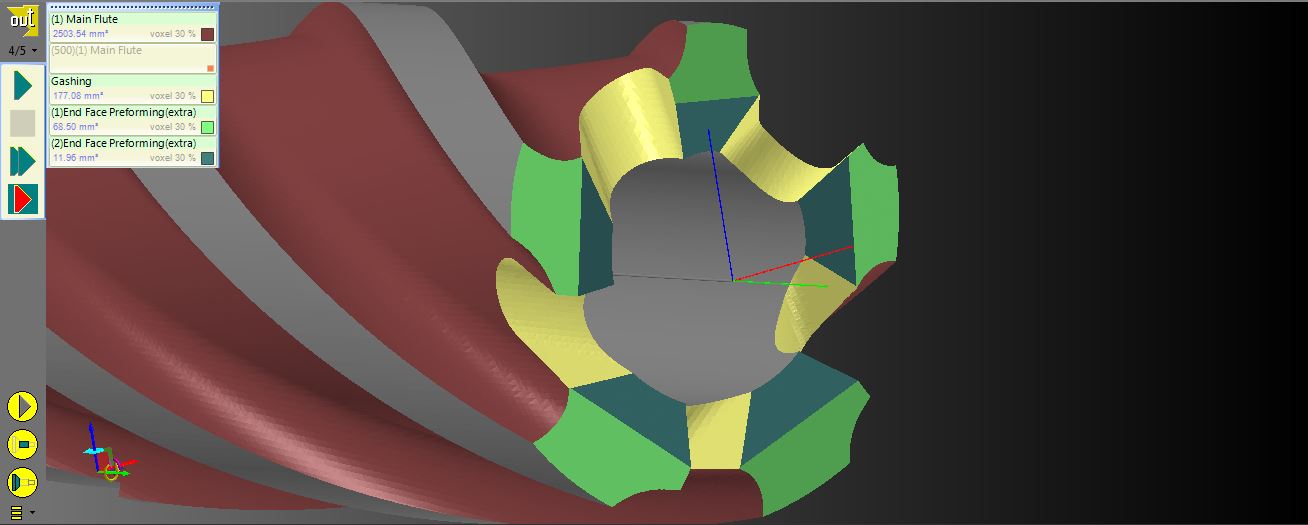

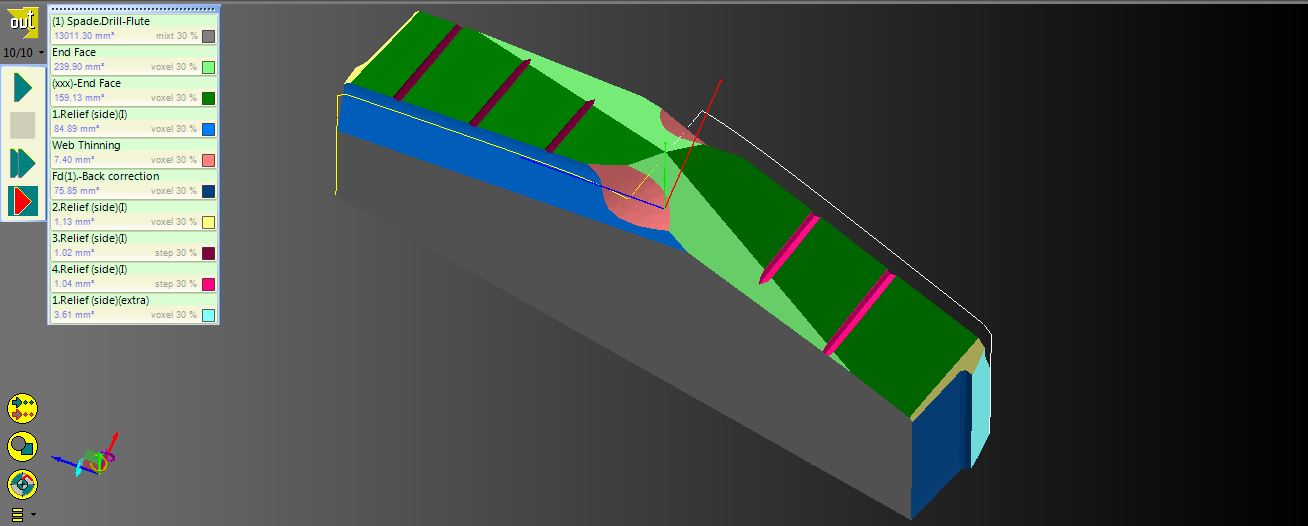

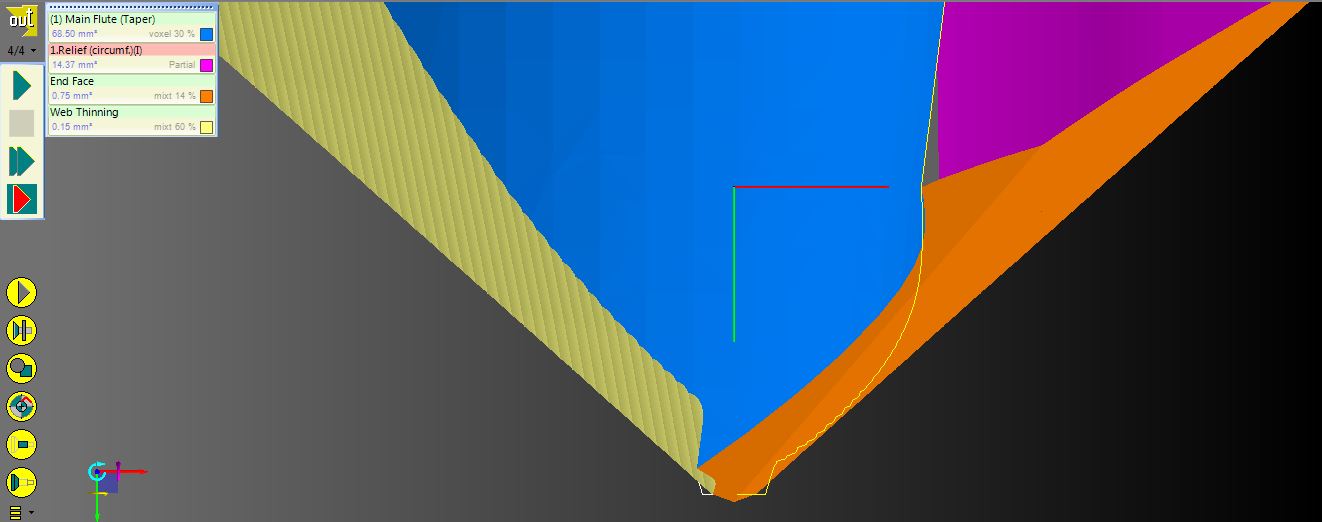

Tool blanks are loaded either manually or with the optional automatic cassette loader or a six axes Fanuc™ robot. A square driver holds the tools between centers, or they can be held by the optional high precision collet mechanism during grinding. When fluting is completed, the online dressing cycle re-trues the wheels for the next part. Dressing is only possible for standard and CBN wheels.

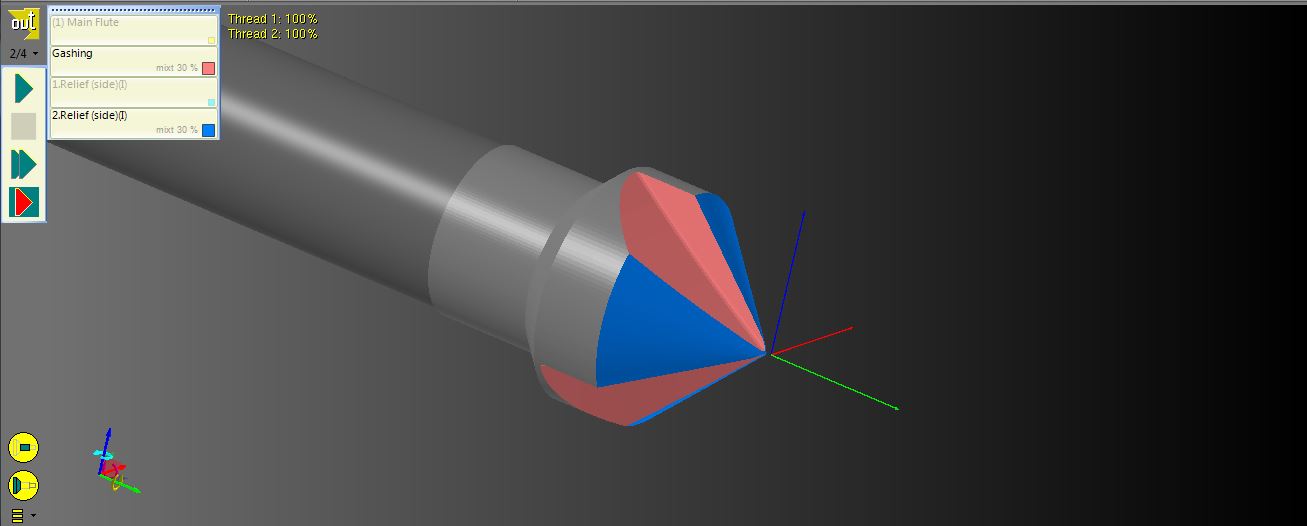

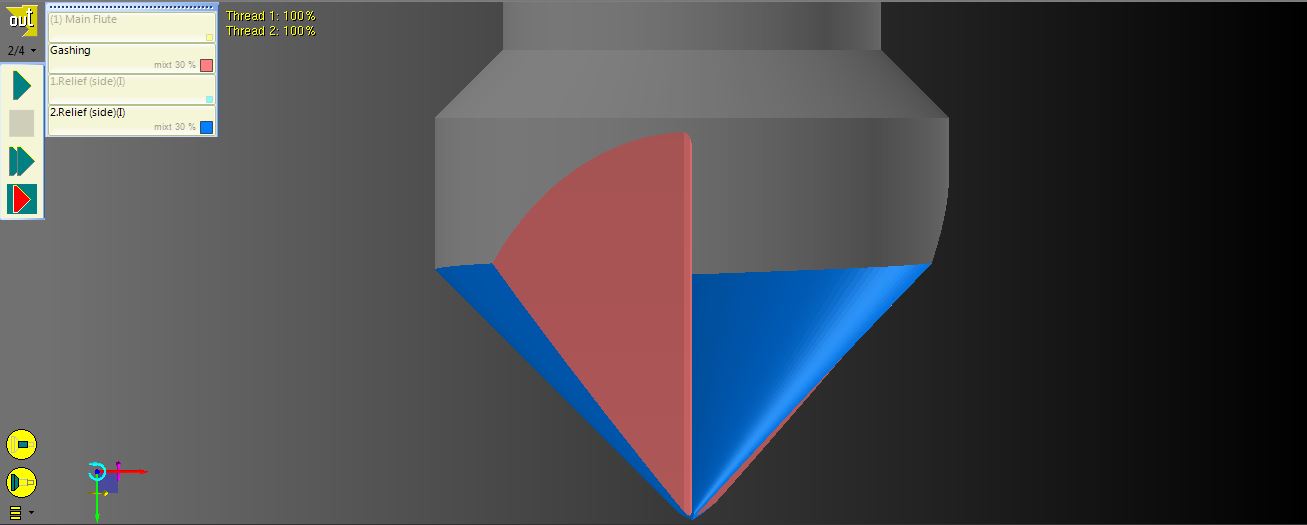

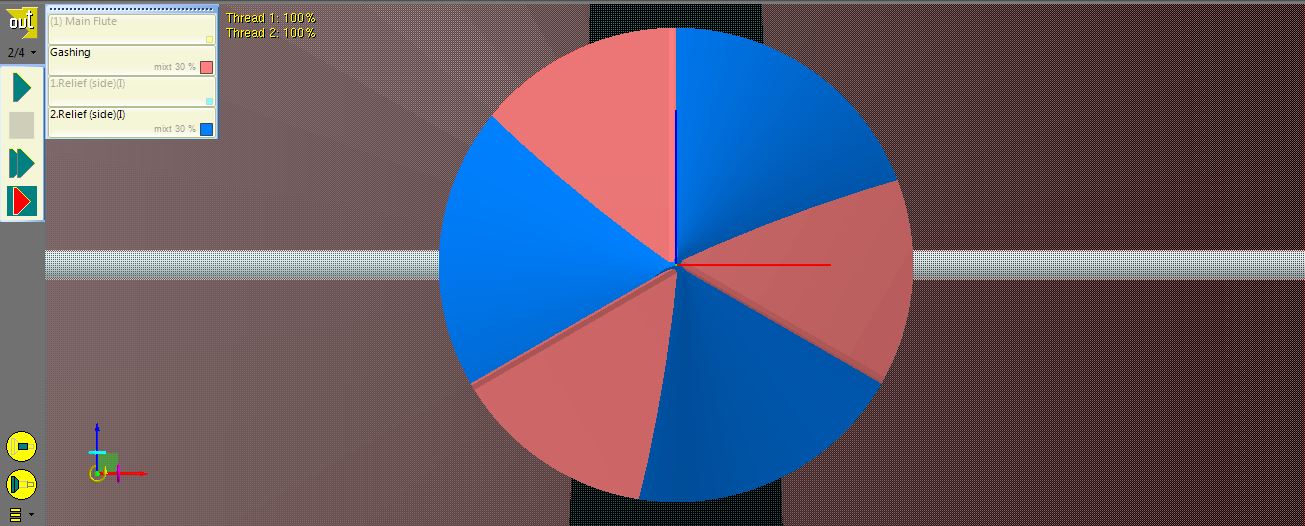

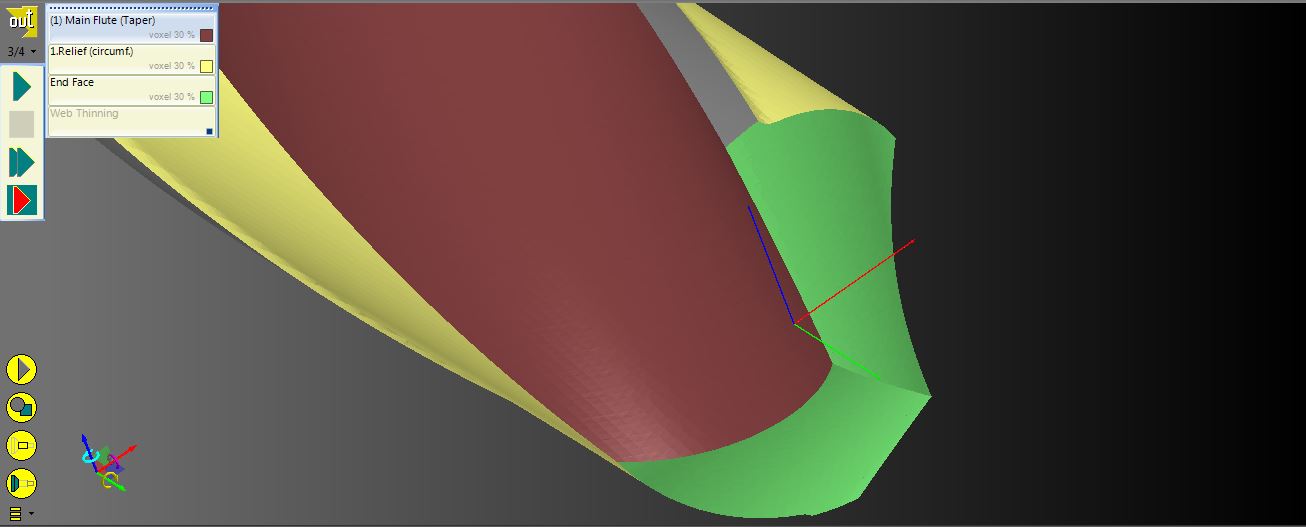

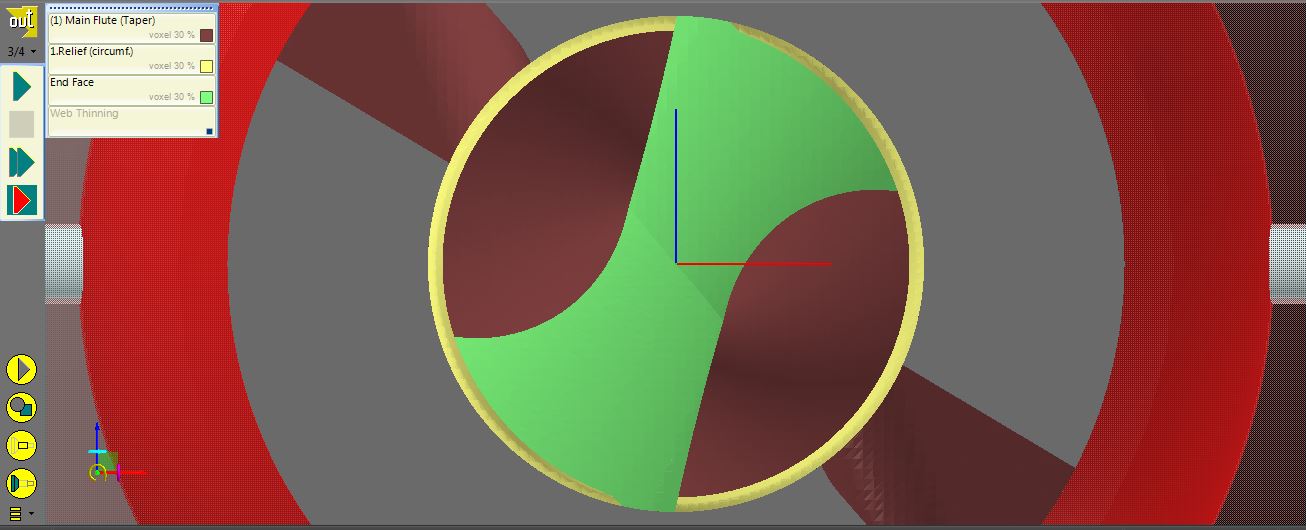

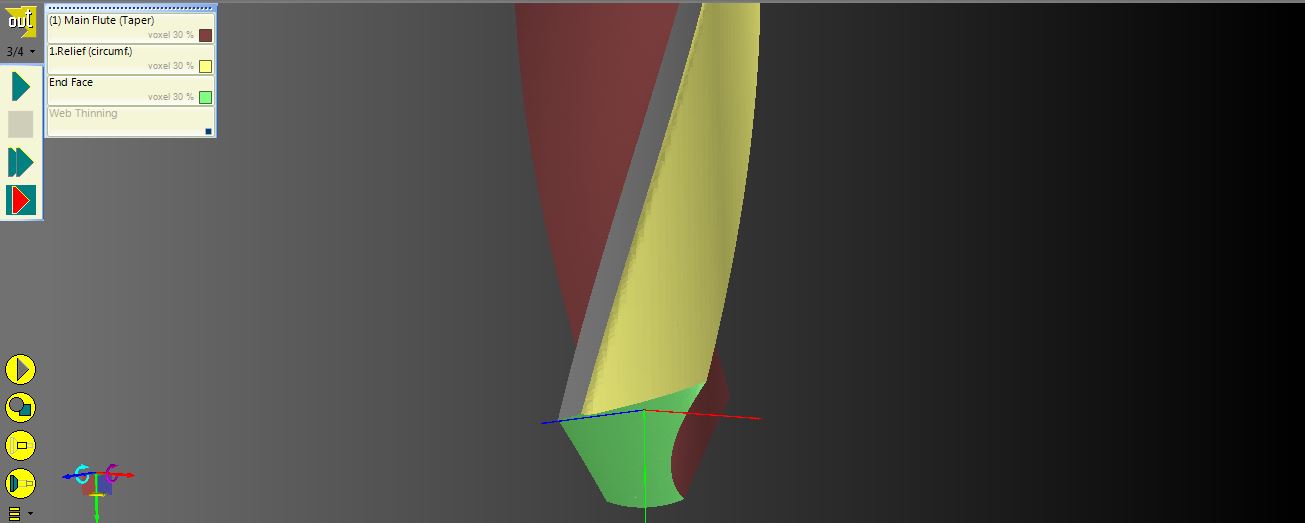

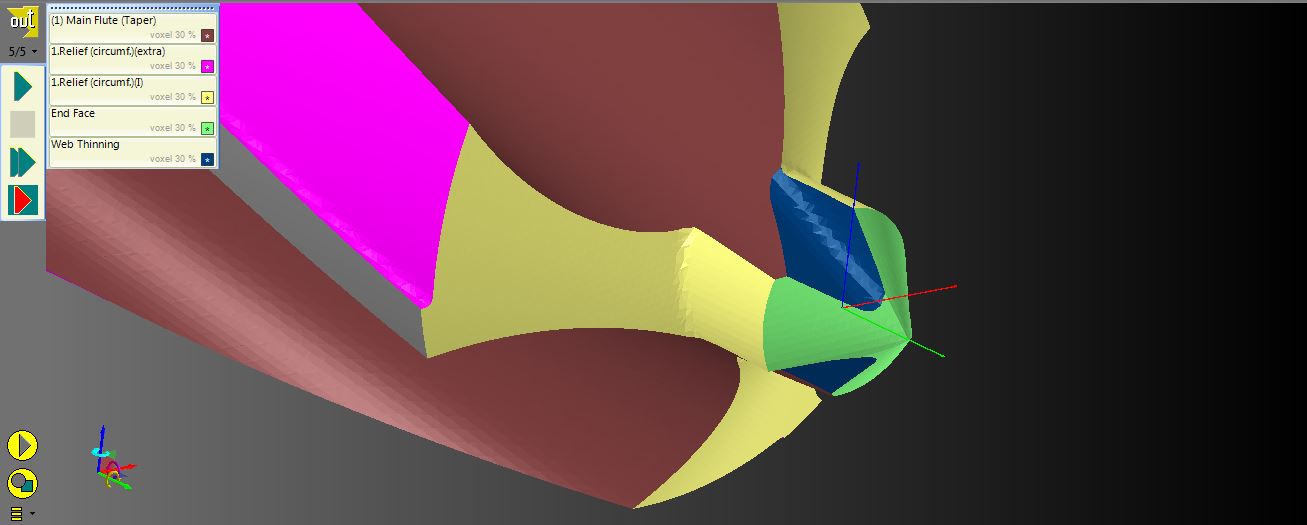

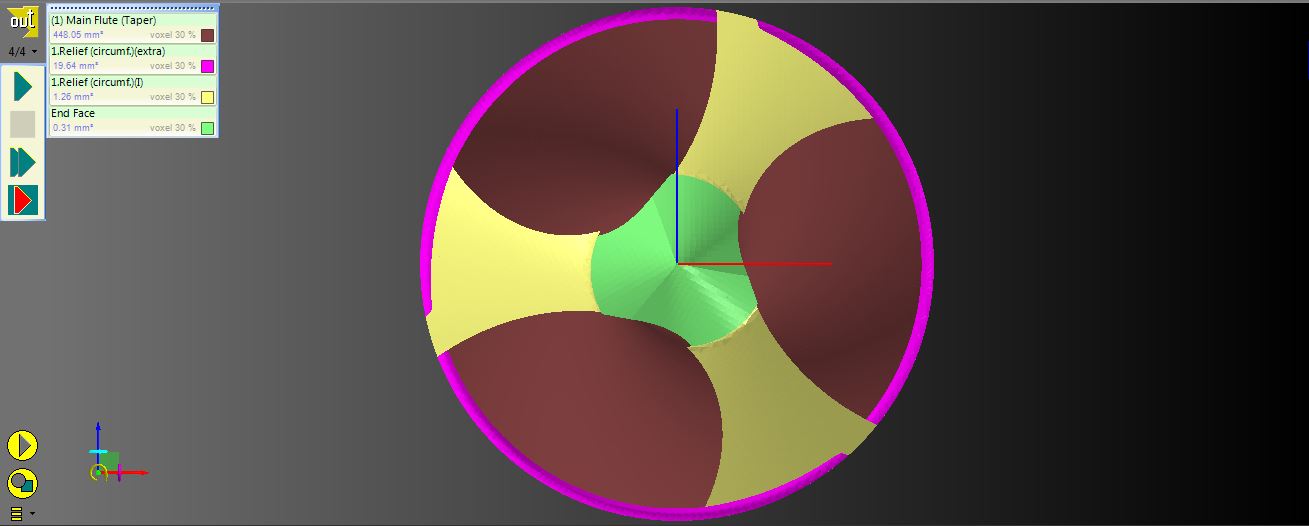

During the flute grinding process, the tools are supported in a center on a sturdy tailstock which is mounted in a fixed position to the machine base. This allows for quick and easy changeovers to different tools because the tip of the tool always determines the location. UFG grinds parts from 2mm to 50mm and can be setup to grind straight flutes, gunnose/spiral point and right-hand or left-hand spiral flutes.

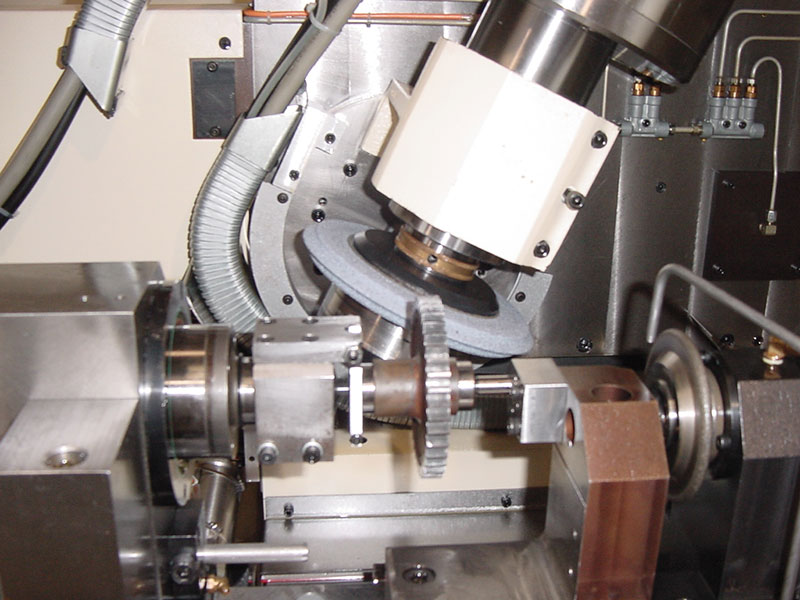

UFG grinding straight and helical gears

UFG with coolant compensator and in-process dressing

ULTRA PRECISION, HIGH PRODUCTIVITY & SHORT CYCLE TIMES

FLEXIBLE SOFTWARE, EFFICIENT & USER FRIENDLY

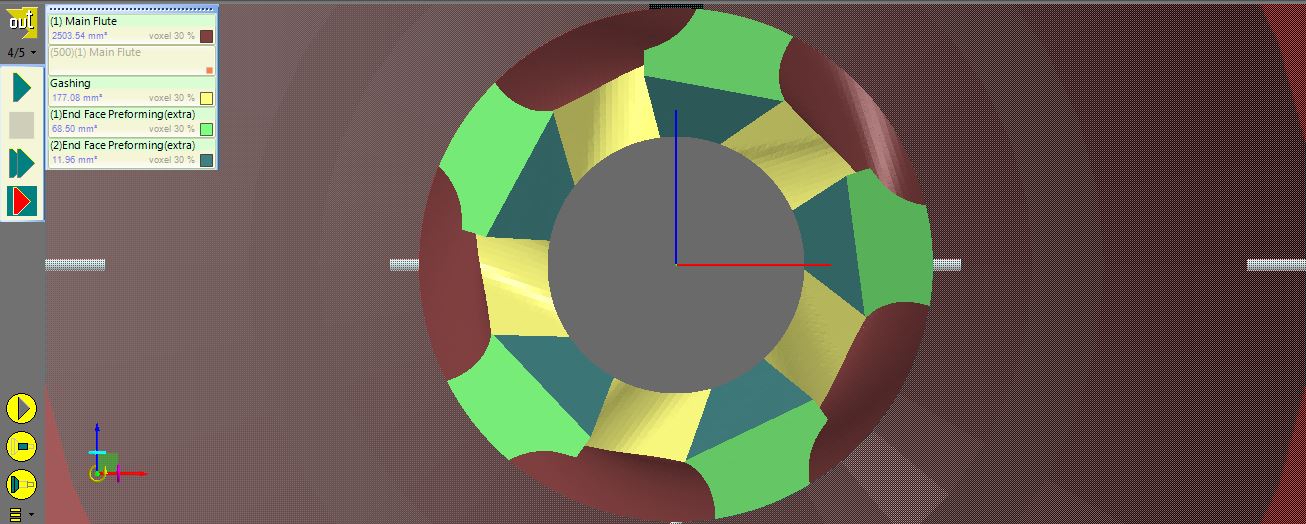

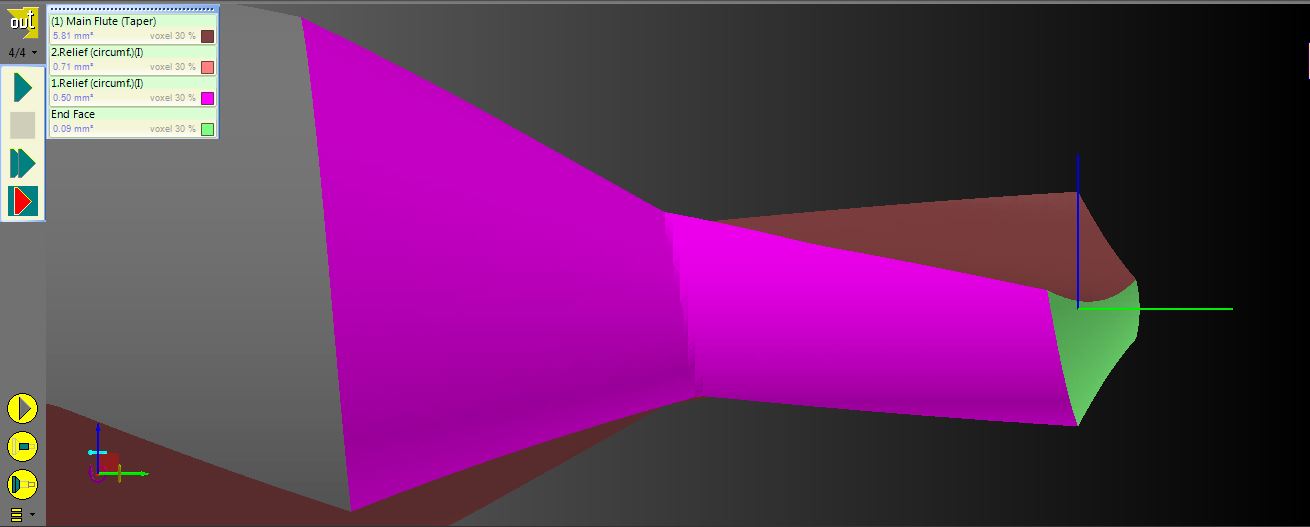

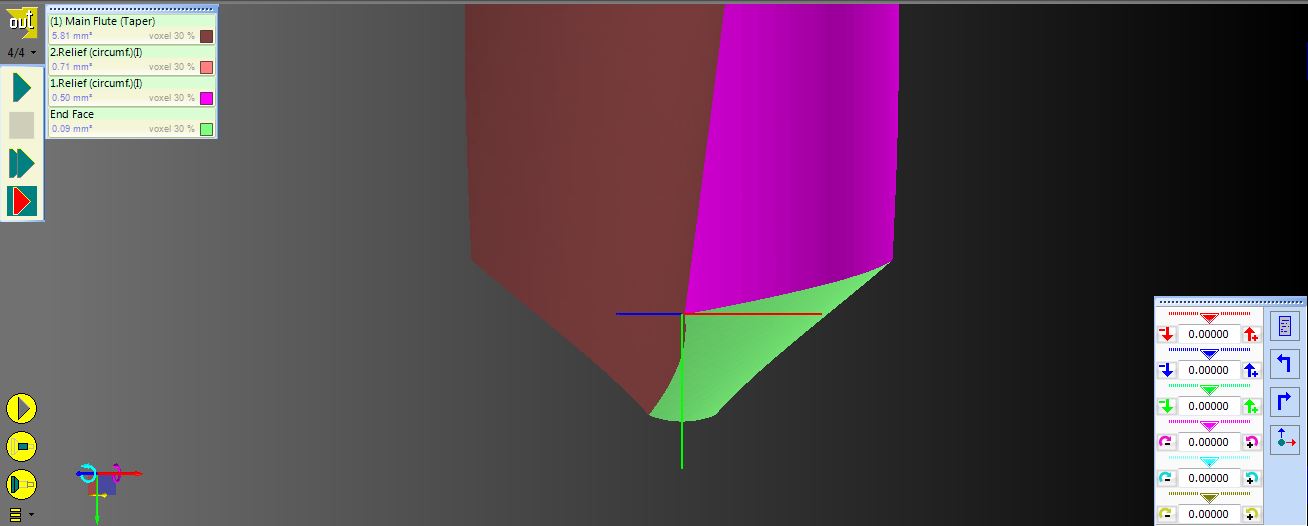

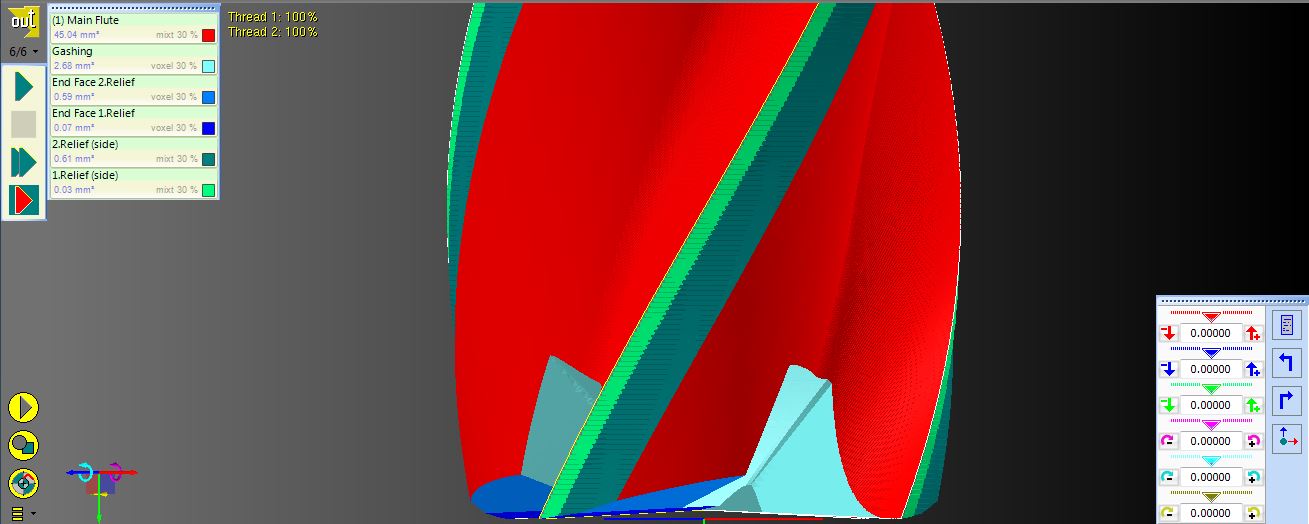

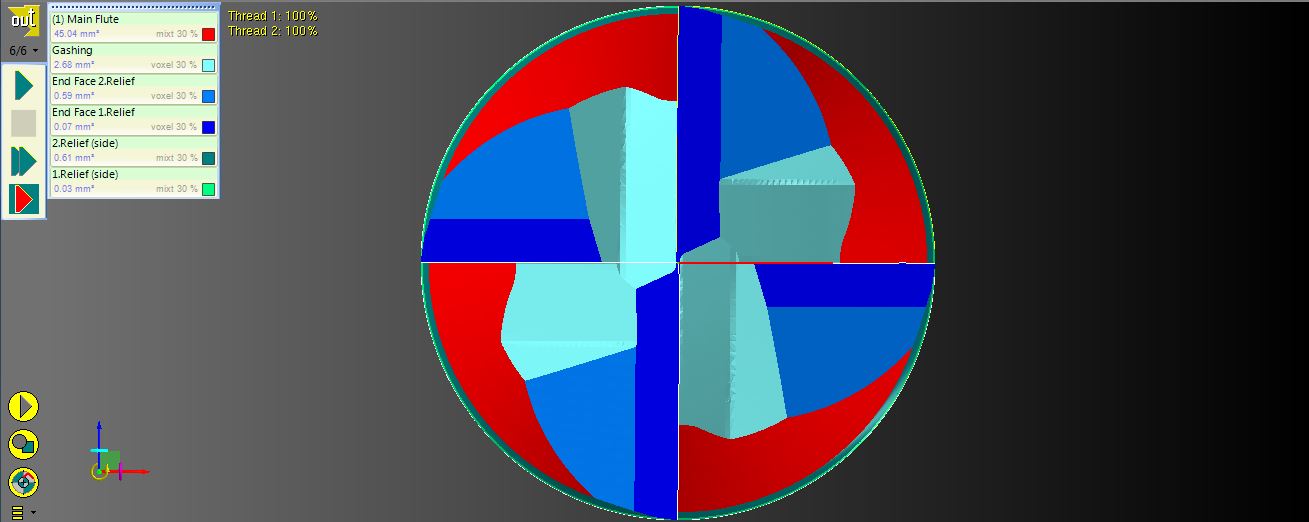

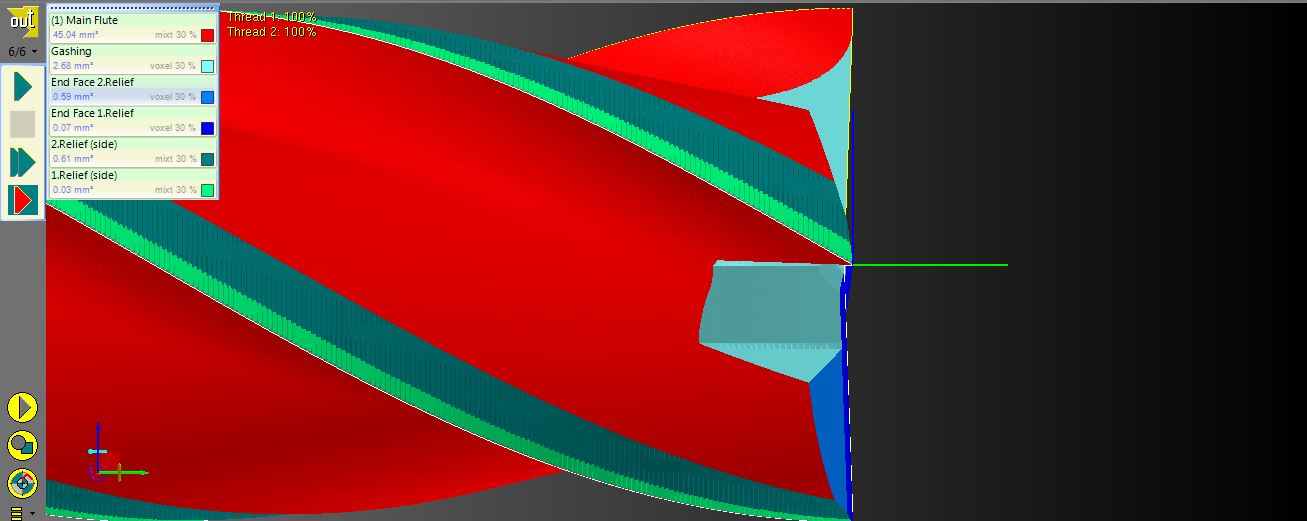

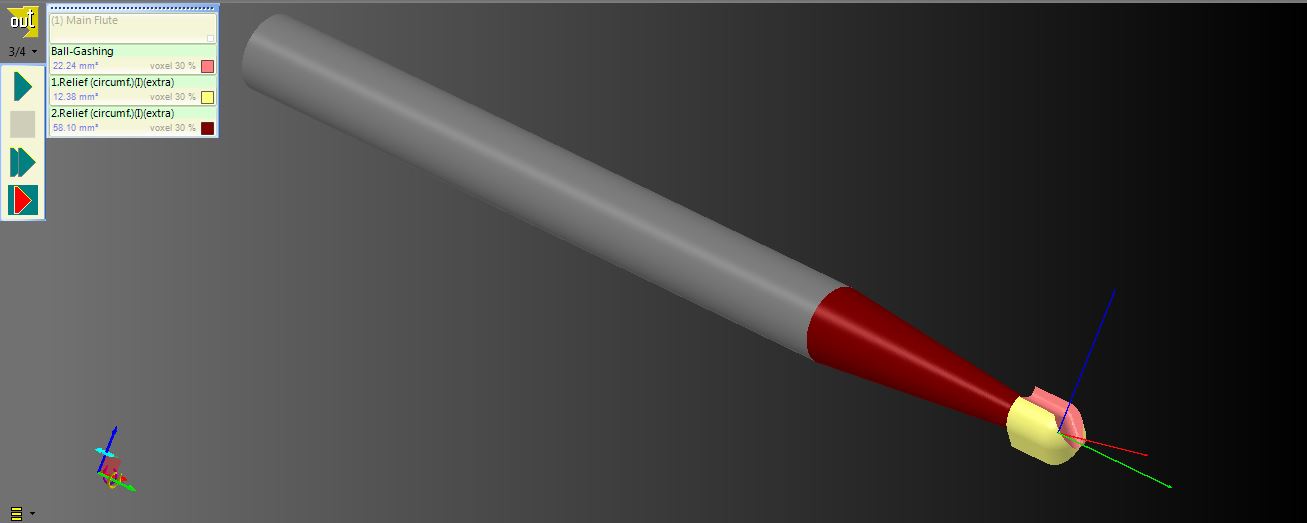

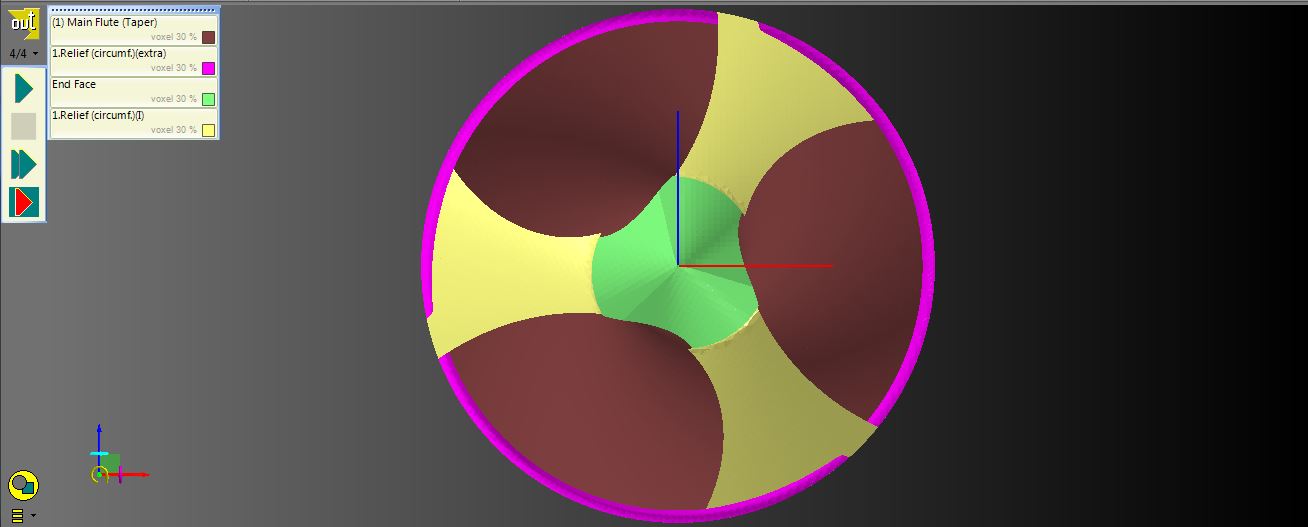

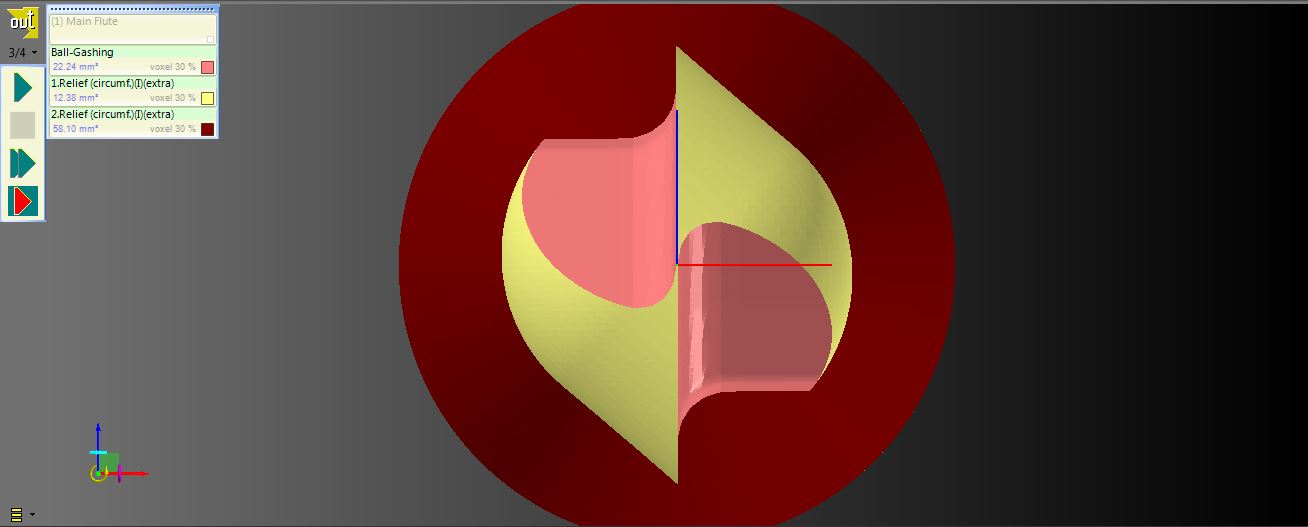

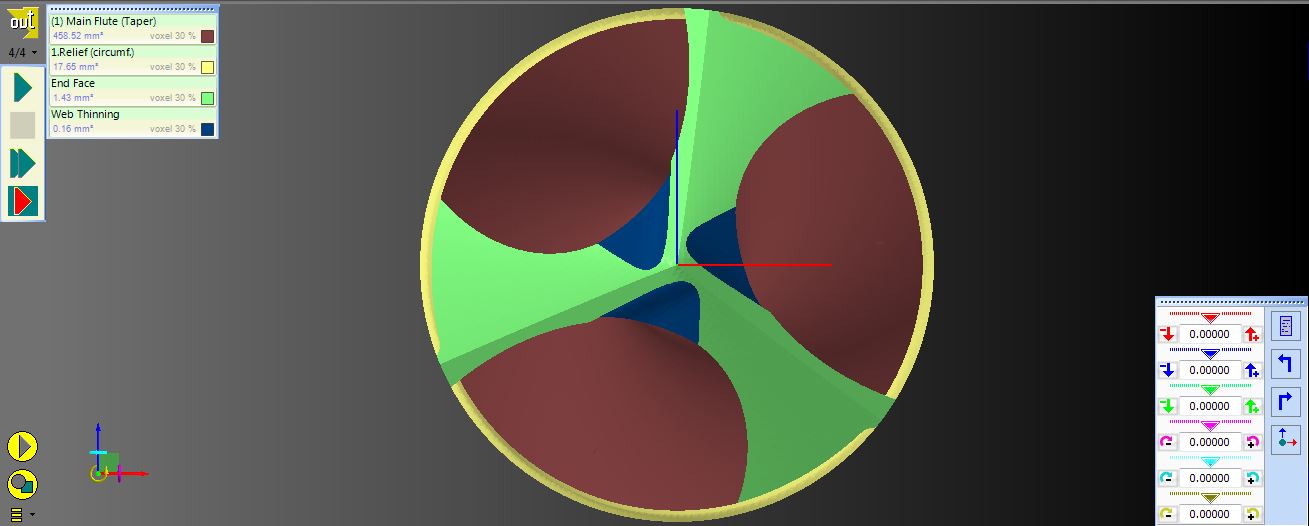

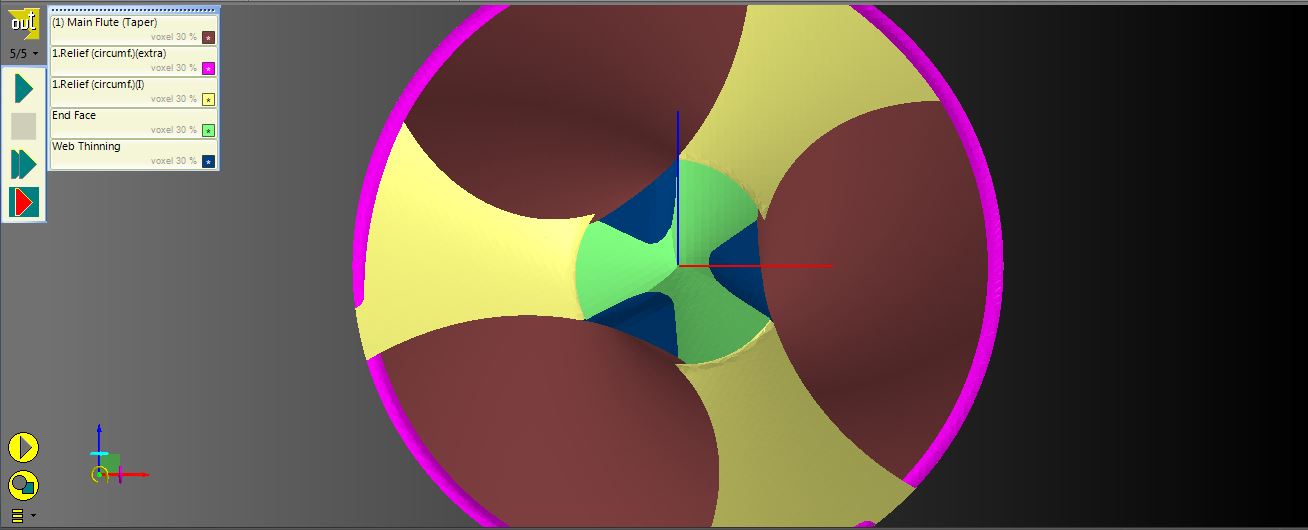

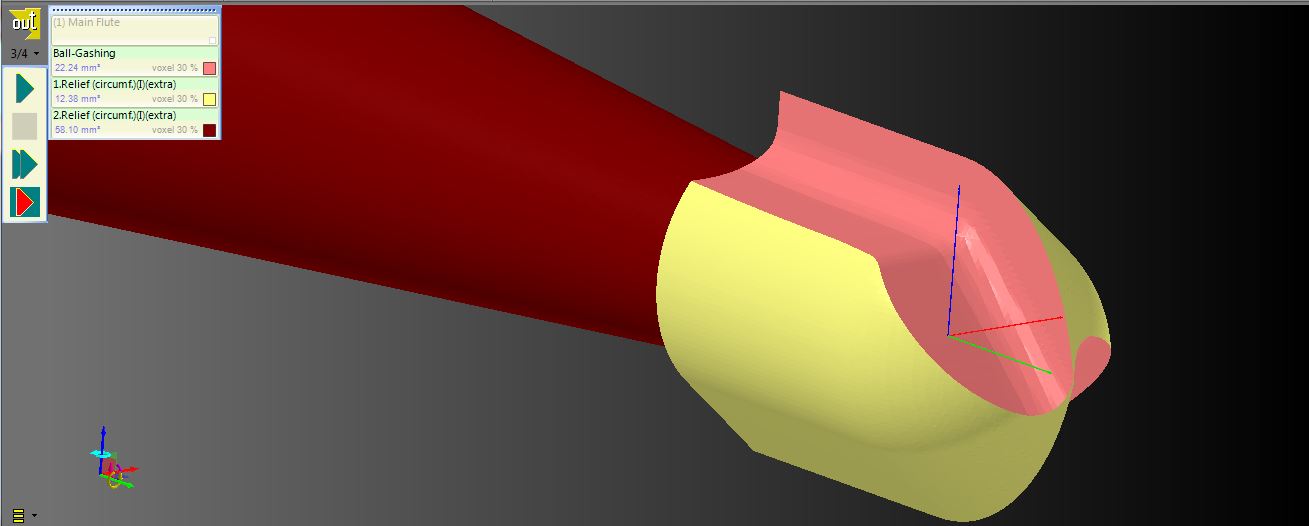

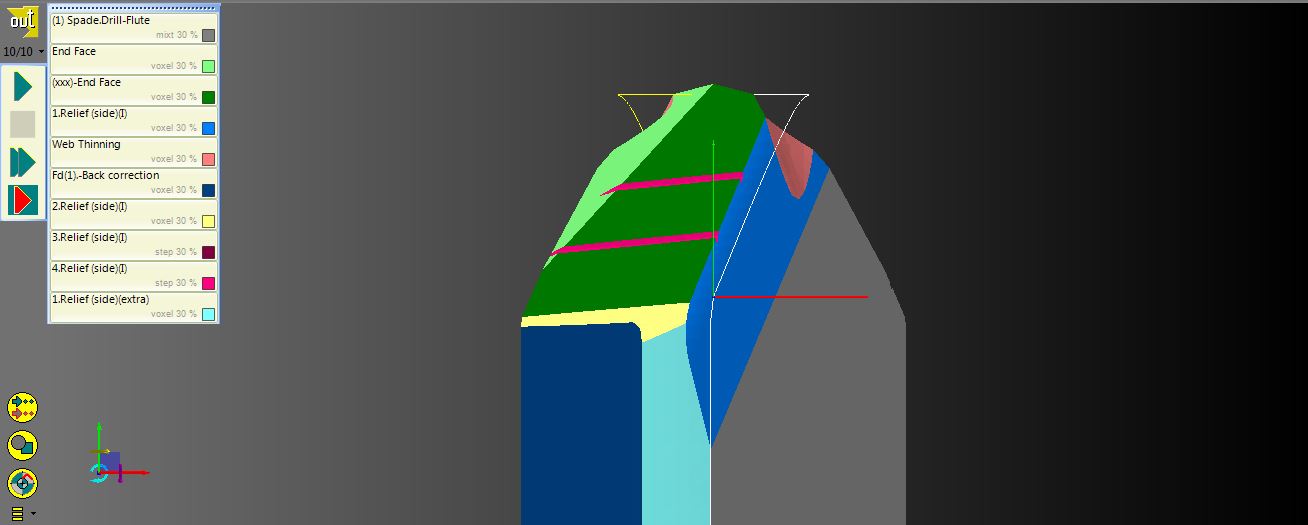

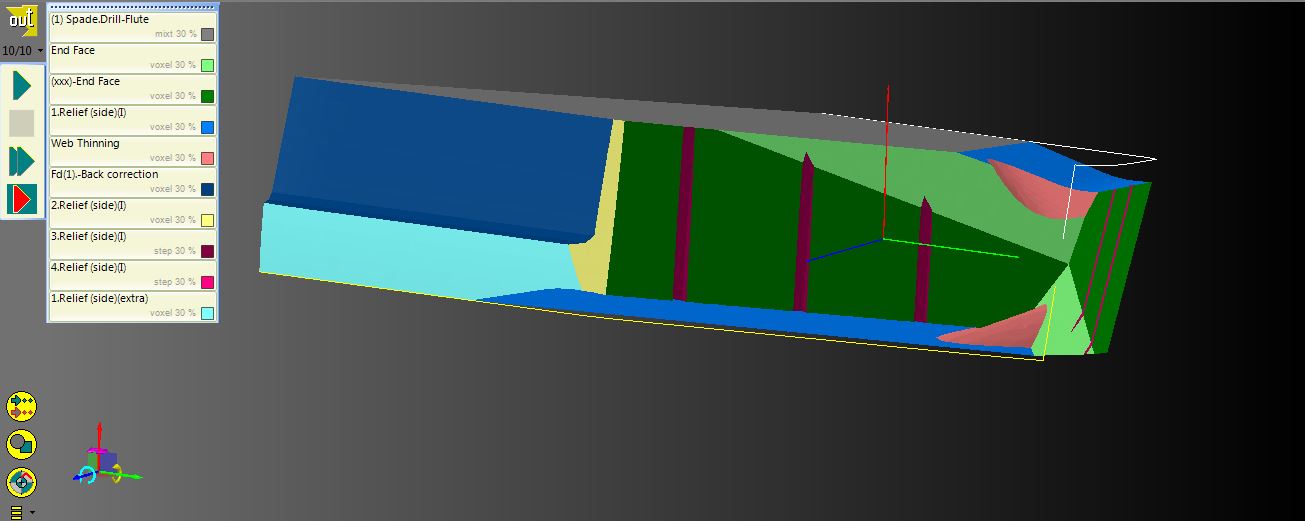

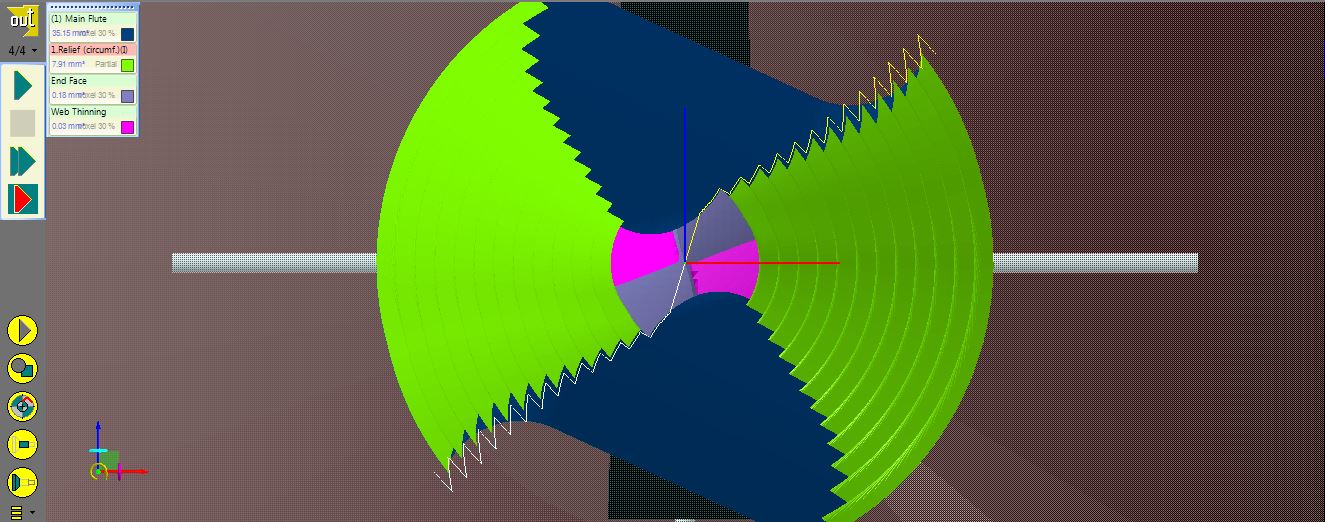

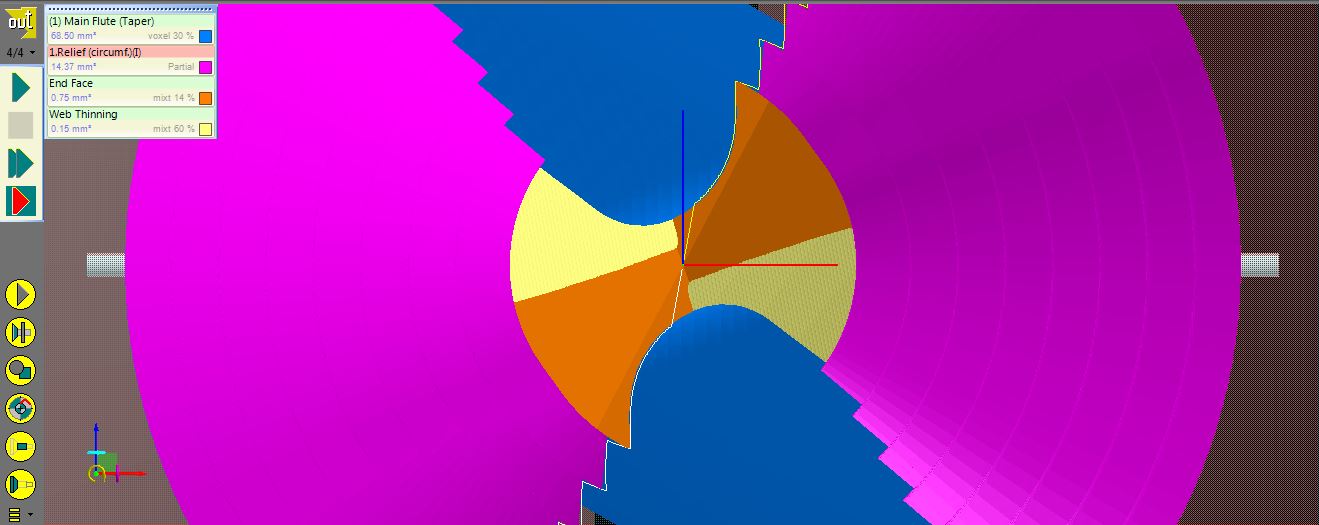

SAMPLE APPLICATIONS / GRINDING OPERATIONS

- Taps: Straight Flutes, right & left hand Flutes, Spiral Point*

- Endmills – Carbide & HSS: Flutes, OD Relief*

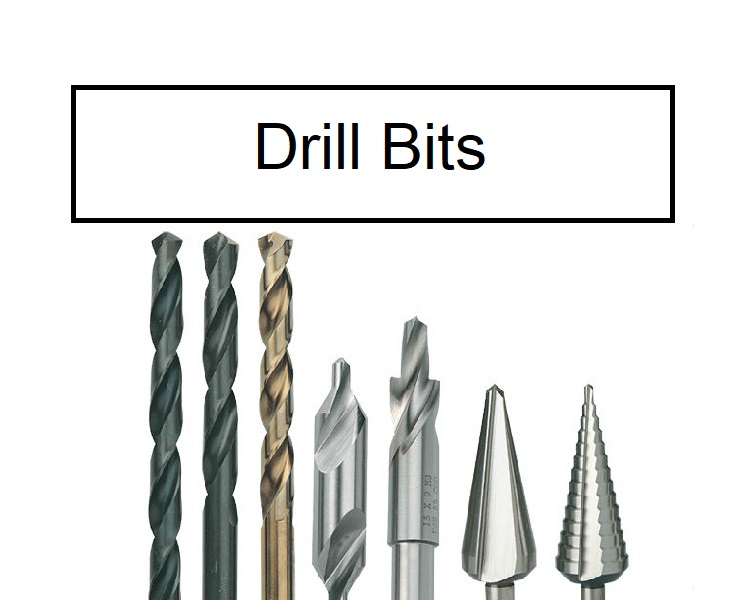

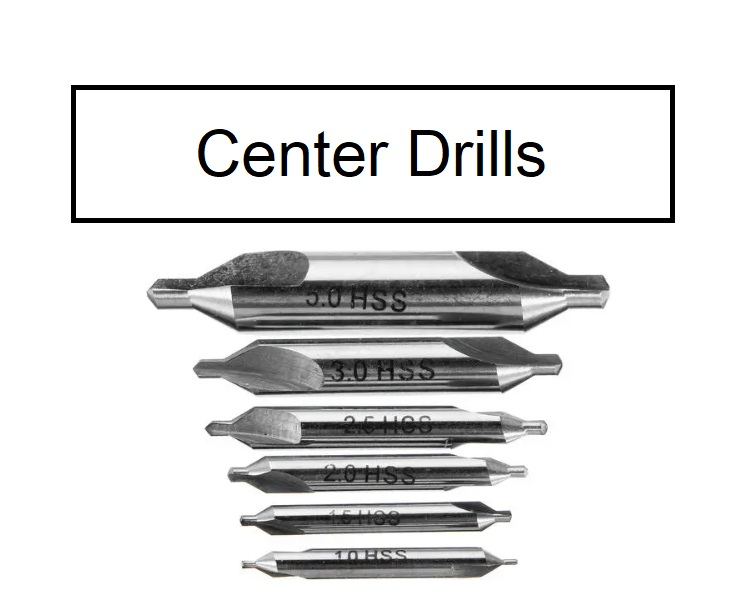

- Twistdrills (Industrial/ Aircraft/ S+D/ DIY/ Medical/ PCB) – Carbide, HSS & Stainless: Flutes, OD Relief*

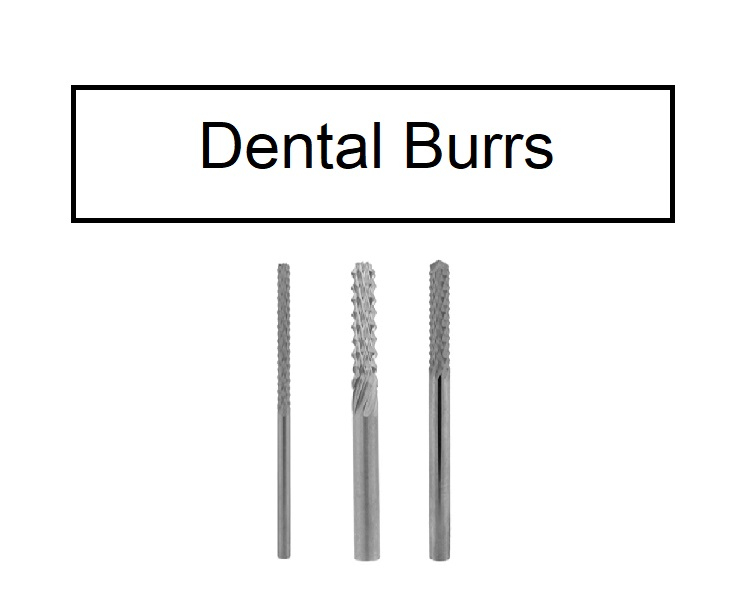

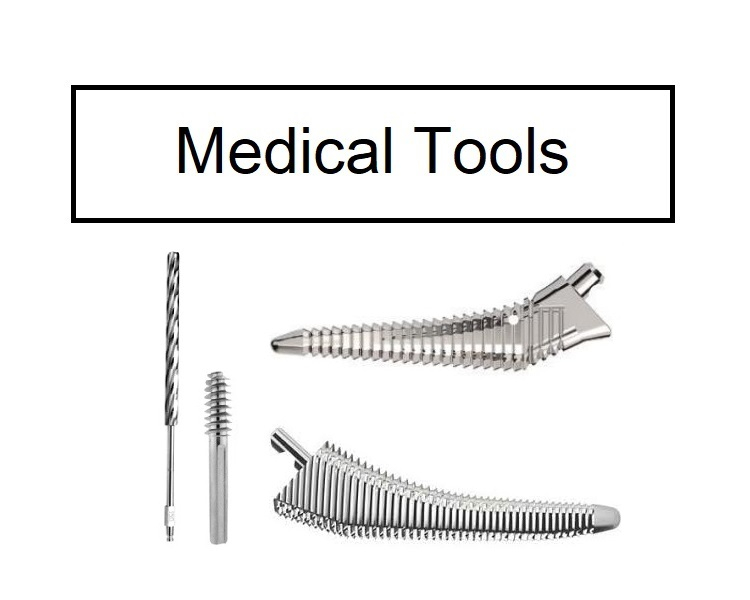

- Medical Tools – Stainless & Titanium: Fluting Drills, Reamers, Burs

- Reamers – Carbide & HSS: Flutes, OD Relief*

- Countersinks – Carbide & HSS: Flutes, Cone Relief, OD*

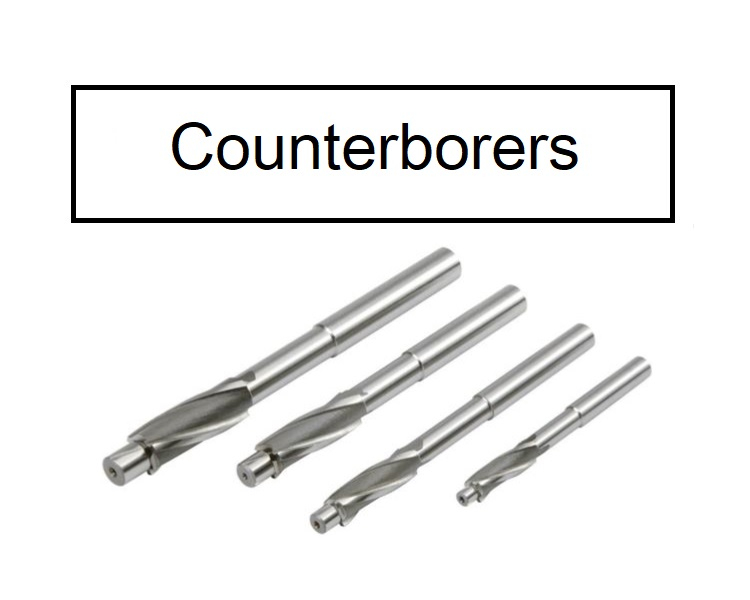

- Counterbores: Flutes, OD Relief, Pilot OD*

- Annular Hole Cutters: Flutes

- Cylindrical Burs – Carbide & HSS: Flutes, Chipbreakers*

- Cylindrical Routers – Carbide & HSS: Right & left hand Flutes*

- Form Relieved Cutters – Flutes, Relief*

* 2nd and 3rd Operation may have to be performed in separate set-ups.