CNC – REBUILD

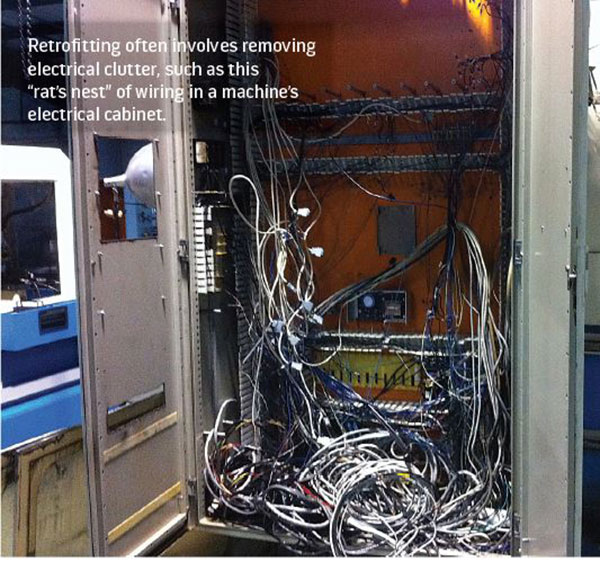

In order to support all of our customers, ITM developed a CNC rebuilding program that offers true OEM quality reconditioning of older machines. Complete rebuild projects have been performed on machines as old as 30+ years. To the utmost satisfaction of our customers, the retrofit program offers replacement controls as well as re-configuring highly responsive drives and motor spindles. Many heavy duty tool grinders and well engineered ITM machines re-gain new life with new and updated Fanuc CNC controllers.

Contact us for more information regarding CNC control rebuild, electrical cabinet rebuild and mechanical rebuild at 386-585-8166.

Scope of CNC Rebuild

• Disassemble the machines completely

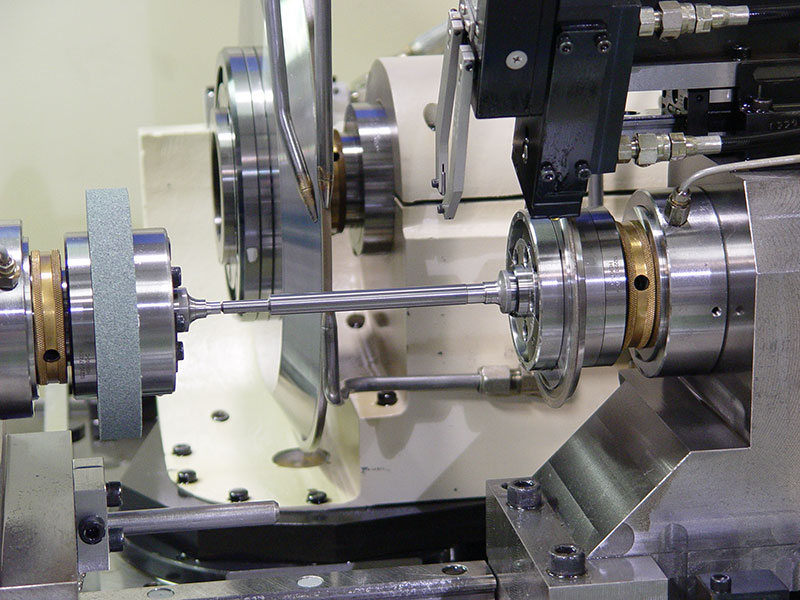

• Rebuild ball screws, spindles, tailstock and slides

• Retrofit machines with new controls, drives etc.

• Provide completely new electrical schematics

• Optimize all servos axes by CNC tunining

• Provide new mechanical assembly drawings

• Repaint complete machines professionally

• Add new features such as automation solutions

Retrofit Packages to Offer

• Package A: Control rebuild only

• Package B: Control rebuild incl. electrical cabinet

• Package C: Mechanical rebuild

• Package D: Mechanical rebuild with automation

• Package E: Mechanical rebuild with QA

• Package F: Post-rebuild training (Mechanical only)

• Package G: Post-rebuild training (Electrical only)

• Package H: Post-rebuild training (Software only)

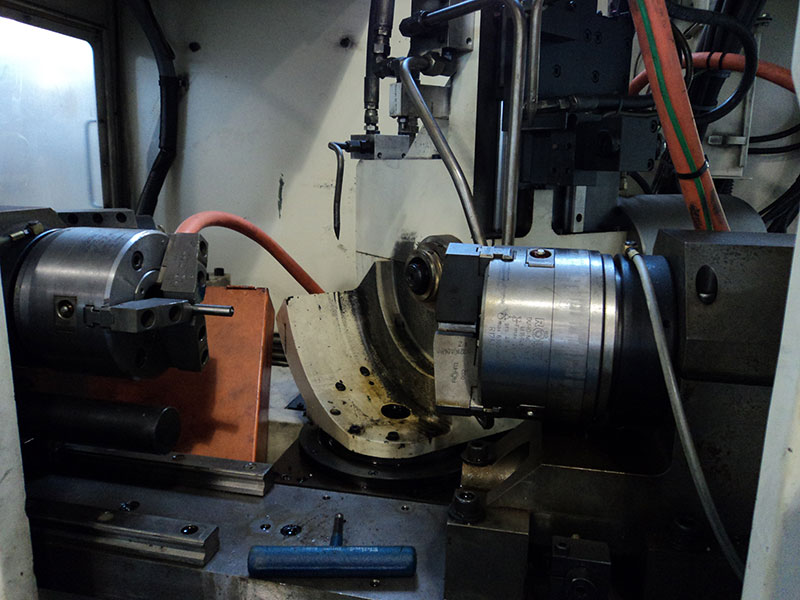

BEFORE

AFTER

BEFORE

AFTER

CNC REBUILD CASE STUDIES

New life for old iron

M. Kelley, mechanical engineer for International Tool Machines, Palm Coast, Fla., emphasized how the company’s retrofits extend the life of the CNC grinding machines ITM builds, which can be 25-plus years old. “The strategy tends to be economical as the retrofit machine runs almost like a new machine,” he said, noting a retrofit is usually 30 to 60 percent of the cost of a comparable new grinder. “Many customers find a high return on investment when an old machine is retrofit.”

Cutting downtime

Overall, Tivoly was pleased with ITM’s results. “It was quite a challenge for ITM because of the machine’s age,” Gowdy concluded. “They were exceptional in working with us on the new software, which they had to program from scratch. They tried to get the old programs out of the old controller, but it wouldn’t give them up.”

Gowdy is especially satisfied with only 2 hours of machine downtime so far this year.